Connect a hose to the cooling water nipple, and connect another hose to the

nipple of the dephlegmator. You will need 170 to 300 litres of cooling water

depending on the quantity of mash. Before heating up, test the cooling of the still.

Let some water flow through the cooling pipes to avoid surprises.

Prepare the appropriate gas burner (26 cm diameter, flat flame) for heating. There

should be a distance of 7 to 10 cm from the gas burner to the bottom plate of the

boiler. (You may purchase a gas burner stand prepared this way from us.) For

safety reasons use the canister with a reductor. The heat up flame and the

distilling flame can be fine-tuned with a tap controlled gas burner.

For electrical operations connect the filament to the mains.

/The 4.5kw filament requires 20 Amperes, while the 6kw filament requires 25

Amperes. The smaller ones may need up to two and half hours heating up time,

while the bigger ones need only two hours. In a consecutive distillation, that is

when the system is still hot, you can save 15-20 minutes in both cases. As for the

electronic operation the longer heat up time is compensated by accurate control

and cheaper operation costs. The temperature in the distillation phase may be

held constant, which makes the process simple as the operator does not have to

monitor the ever changing tiny gas flame coming out of the canister./

Set the controller to 100% and before the foreshot starts to flow regulate the

4.5kw filament to 70%, and the 6kw filament to 60%.

Turn on the digital thermometer. If it does not turn on, remove the battery saving

foil in the back of the unit.

Create a pedestal at the condenser's end. Put a measure next to the pipe's end.

The measure will collect the heads. Prepare the eprouvette, the hydrometer with

thermometer and a pot or jar to collect the heart run.

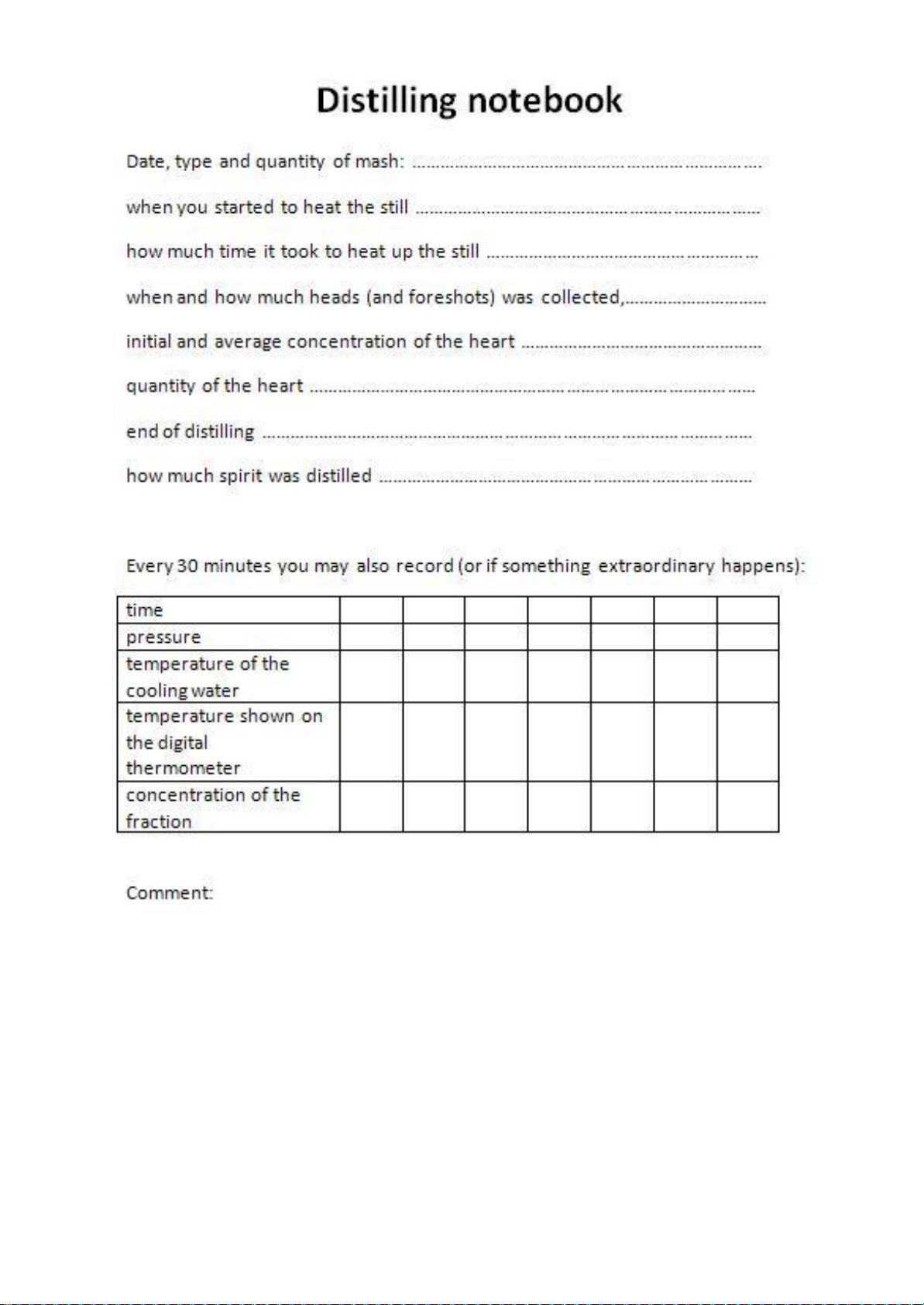

Keep a distilling notebook. The documented data may serve useful information in

the future. Record the following in the template provided:

Date, type and quantity of mash, when you started to heat the still, how much

time it took to heat up the still, when and how much heads (and foreshots) was

collected, initial and average concentration of the heart, quantity of the heart, end

of distilling, how much spirit was distilled. Every 30 minutes you may also record

(or if something extraordinary happens): the time, pressure, temperature of the

cooling water, temperature shown on the digital thermometer, concentration of

the fraction.