−B19 −− B18 −

English

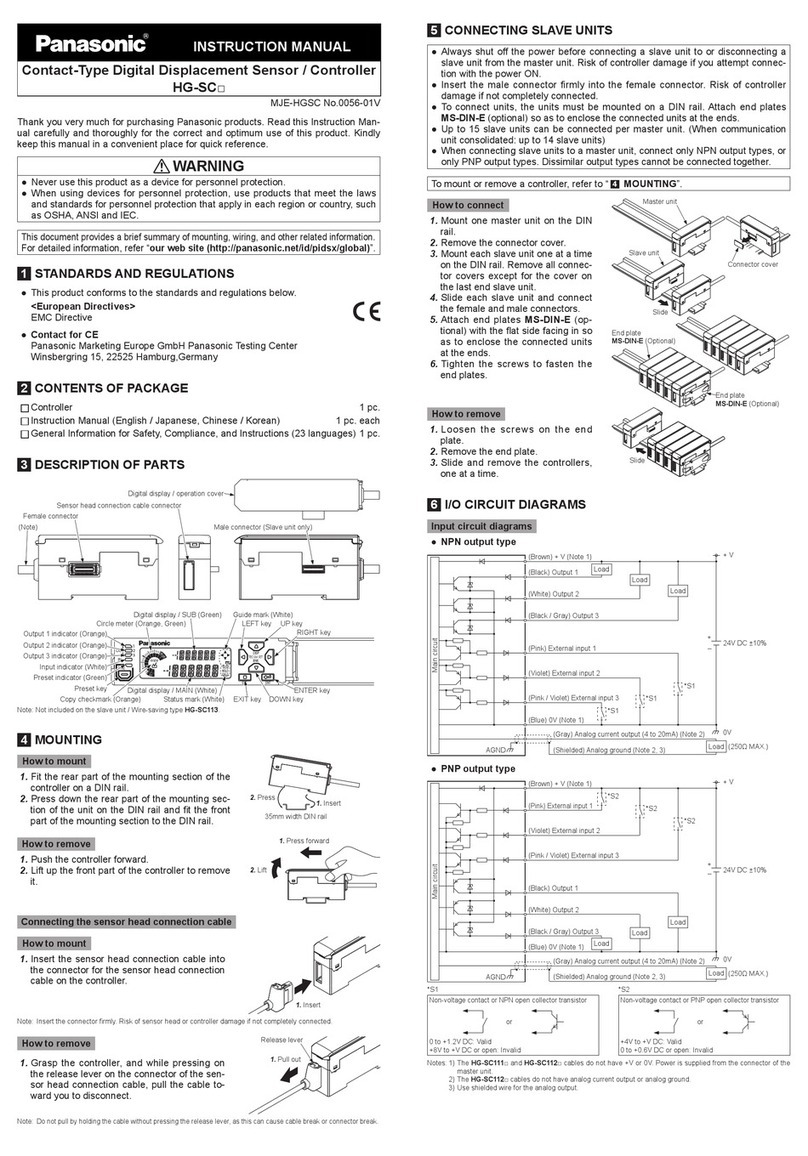

3. System Conguration and Wiring

Wiring of the Main Circuit (Terminal block type)

3. System Conguration and Wiring

Wiring of the Main Circuit (Terminal block type)

G-frame, 200 V type

•Wiringshouldbeperformedbyaspecialistoranauthorizedpersonnel.

•Donotturnonthepoweruntilthewiringiscompleted.

•

Nevertouchtheterminaltowhichhighvoltageisapplied.Thereisariskofelectricshock.

• Tips on Wiring

1)Takeoffthecoverxingscrews,anddetachtheterminalcover.

2)Makewiring

Useclamptypeterminalsofroundshapewithinsulationcoverforwiringtothe

terminalblock.Forcablediameterandsize,reterto"DriverandListofApplicable

PeripheralEquipments"(P.B16).Tightentheterminalblockscrewwithatorque

between2.0and2.4N•m(leftside)and1.0and1.7N•m(rightside).

3)Attachtheterminalcover,andxwithscrews.

TightenthescrewsecuringthecoverwiththetorquewrittenonP.B17.

Motor

Varistor

DC

24V

L1

U

V

W

E

L2

L3

B1

B2

NC

U

V

W

NC

L1C

L2C

NC

NC

DB1

DB2

NC

NC

DB3

DB4

NC

• Check the name plate of the driver for power

specifications.

• Provide a residual current device. The

residual current device to be the one designed

for "Inverter" and is equipped with counter-

measures for harmonics.

• Provide a circuit breaker.

• Make sure to provide a noise filter.

• Provide coil surge suppression units to the coil

of the Magnetic Contactor recommended by

manufacturer. Never start/stop the motor with

this Magnetic Contactor.

• Provide an AC Reactor (to be supplied by customer).

• The voltage applied across DB1 and DB2 must

be 300 VAC or below or 100 VDC or below.

• Match the connector of the motor and driver “U,

V, W”.

• Avoid shorting and grounding.

Don't connect the main power.

• For normal operation, do not disconnect the

shorting bar from DB3 and DB4: remove the bar

only when the external dynamic brake resistor

is used.

• Earth-ground this.

•

To prevent electric shock, be sure to connect the

ground terminal ( ) of the driver, and the ground

terminal (ground plate) of the control panel.

The ground terminal ( ) must not be shared

with other equipment.

Two ground terminals are provided.

• Don't connect the earth cable to other

inserting slot, nor make them touch.

• Compose a duplex Brake Control Circuit so that

the brake can also be activated by an external

immediate stop signal.

• The holding brake has no polarities.

• For the holding brake power supply capacity

and how to use the brake, refer to “Specifica-

tions of Built-in Holding Brake” on P.B47.

• Provide a varistor.

• Connect a 10A fuse in series with the varistor.

* Do not connect anything to NC.

Ground resistance: 100 Ω max.

For applicable wire, refer to P.B16.

Left

side Right

side

DC power

supply

for brake

Fuse (125 V 10 A)

MCCB

Power

supply NF MC

L

RCD

H-frame, 200 V type

•Wiringshouldbeperformedbyaspecialistoranauthorizedpersonnel.

•Donotturnonthepoweruntilthewiringiscompleted.

•

Nevertouchtheterminaltowhichhighvoltageisapplied.Thereisariskofelectricshock.

• Tips on Wiring

1)Takeoffthecoverxingscrews,anddetachtheterminalcover.

2)Makewiring

Useclamptypeterminalsofroundshapewithinsulationcoverforwiringtothe

terminalblock.Forcablediameterandsize,reterto"DriverandListofApplicable

PeripheralEquipments"(P.B16).Tightentheterminalblockscrewwithatorque

between0.7and1.0N•m(upperside)and2.2and2.5N•m(lowerside).

3)Attachtheterminalcover,andxwithscrews.

TightenthescrewsecuringthecoverwiththetorquewrittenonP.B17.

Power

supply

Motor

Varistor

DC

24V

L1

U

V

W

E

L2

L3

B1

B2

NC

U

V

W

L1C

L2C

DB1

DB2

• Check the name plate of the driver for power

specifications.

• Provide a residual current device. The

residual current device to be the one

designed for "Inverter" and is equipped with

countermeasures for harmonics.

• Provide a circuit breaker.

• Make sure to provide a noise filter.

• Provide coil surge suppression units to the coil

of the Magnetic Contactor recommended by

manufacturer. Never start/stop the motor

with this Magnetic Contactor.

•

The voltage applied across DB1 and DB2 must

be 300 VAC or below or 100 VDC or below.

• Provide an AC Reactor

(to be supplied by customer)

.

• Do not connect anything to NC.

• Match the connector of the motor and driver

“U, V, W”.

• Avoid shorting and grounding.

Don't connect the main power.

• Earth-ground this.

• To prevent electric shock, be sure to connect

the ground terminal ( ) of the driver, and the

ground terminal (ground plate) of the control

panel.

• The ground terminal ( ) must not be shared

with other equipment.

Two ground terminals are provided.

• Don't connect the earth cable to other

inserting slot, nor make them touch.

• Compose a duplex Brake Control Circuit so

that the brake can also be activated by an

external immediate stop signal.

• The holding brake has no polarities.

• For the holding brake power supply capacity

and how to use the brake, refer to “Specifica-

tions of Built-in Holding Brake” on P.B47.

• Provide a varistor.

• Connect a 10A fuse in series with the varistor.

Ground resistance: 100 Ω max.

For applicable wire, refer to P.B16.

DC power

supply

for brake

Fuse (125 V 10 A)

MCCB

NF MC

L

RCD

Upper

side

Lower

side

Power supply for

regenerative resistor

DC

24V