IN-SERVICE OOLS -

AF ER OOLS HAVE BEEN IN SERVICE:

NEW OOLS -

BEFORE PLACING IN O SERVICE:

INSPEC ION/MAIN ENANCE

VISUAL INSPEC ION

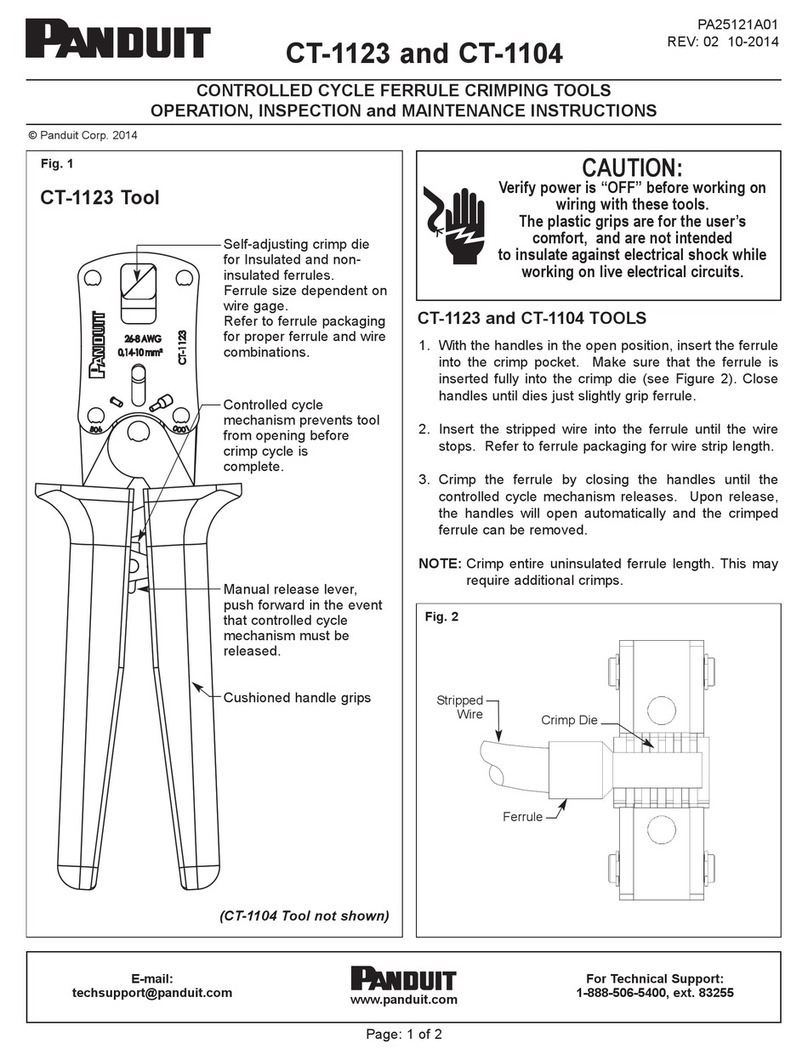

1. Visually inspect the tool for missing or loose

pins, then close the tool and note the return

action of the handles.

2. Inspect the crimping dies for worn, chipped

or broken edges.

3. If parts are missing, defective or damaged,

contact Panduit Customer Service for

information on repair or replacement of tools.

ROUBLESHOO ING

DIE CLOSURE INSPEC ION

Die closure is measured by using G /N G gage members (dimensions listed in Table 1).

PRELOAD FORCE INSPEC ION

1. Clean the crimping dies and gage member surfaces.

2. Close the tool handles until the crimping dies are bottomed and the controlled cycle mechanism

releases. Keep the handles closed together.

3. Using the appropriate gage member, attempt to insert the N G gage into the die opening. The N

G side may partially enter the die closure but must N T pass completely through. Perform this test

as shown in Table 1.

4. Repeat Step 3 with the appropriate G gage as shown in Table 1. The G side must enter and pass

completely through the die closures.

5. If both gage conditions are met, the tool is dimensionally correct. If either condition fails, contact

Panduit Customer Service.

1. Close the handles until the controlled cycle

mechanism is engaged, but before the

mechanism releases.

2. Apply a force to the handles 1-1/4" (32 mm)

from the end of the handles, until the

controlled cycle release mechanism

releases. Record the reading using a force

gauge.

3. The force required to release the controlled

cycle release mechanism should be a

minimum of 15 pounds-force (67 N). If the

force required is less than 15 pounds-force

(67 N), contact Panduit Customer Service.

able 1

Page: 2 of 2

All Panduit crimping tools are calibrated and

inspected before they are shipped from the

factory. All new tools should be inspected before

being used.

New tools are shipped, factory lubricated, in

protective packaging. After inspection, simply

clean any excess oil from the crimping dies and

place into service.

When the tool is not in use, keep the handles

closed to prevent objects from becoming lodged

in the crimping area. Store the tool in a clean, dry

area.

It is recommended that each operator of the tool be made aware of - and responsible for following these

maintenance steps.:

In-service tools should be cleaned and inspected at least NCE A M NTH. To clean-wipe with a clean

cloth.

In-service tools should be lubricated NCE A WEEK, and after every cleaning. Lubricate all pins,

pivots and bearing surfaces with D W C RNING Molykote BR2 Plus. Do not use oil excessively.

Be sure to clean any excess oil from the crimping dies before using.

® Molykote BR2 Plus is the Registered Trademark of D W C RNING

DIE CLOSURE GO / NO GO GAGE MEMBERS - OOL NO. C -300-1

CRIMP

P CKET

AWG / mm2

ENGLISH G / N G GAGE MEMBERS METRIC G / N G GAGE MEMBERS

“G” Dia. (G ) “NG” Dia. (N G ) “G” Dia. (G ) “NG” Dia. (N G )

22-14 / 0,5-2,5 .062” .072” 1.57 mm 1.83 mm

C -300-1

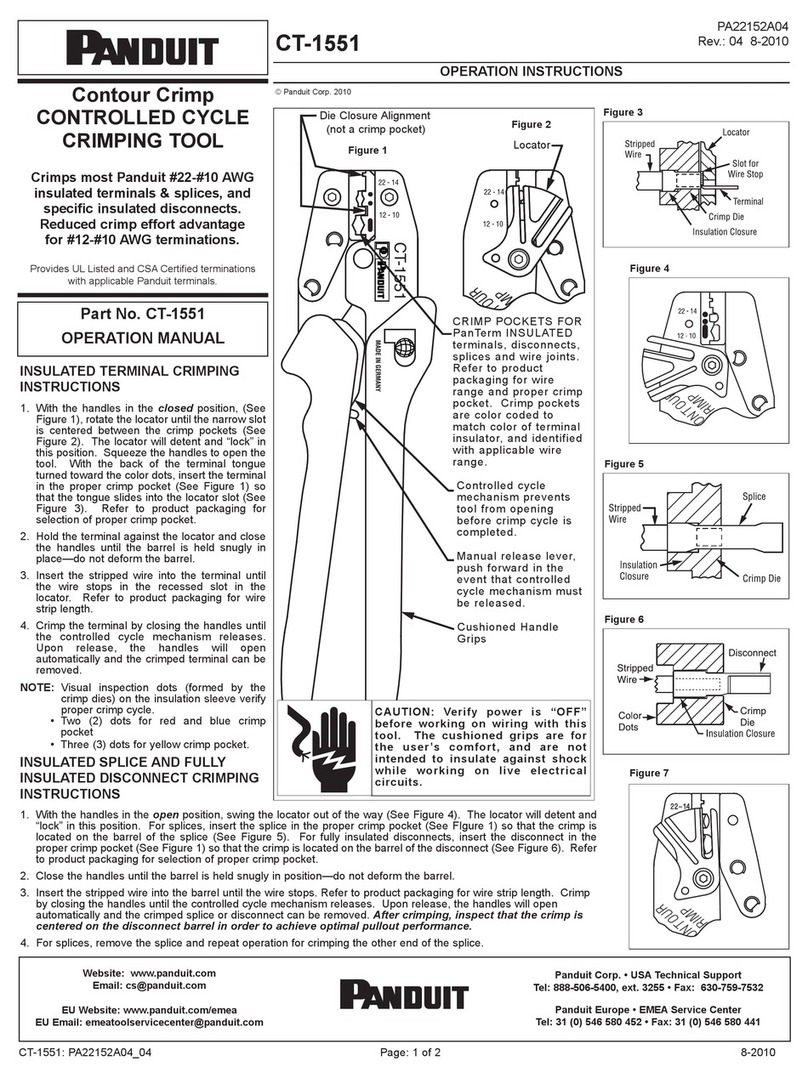

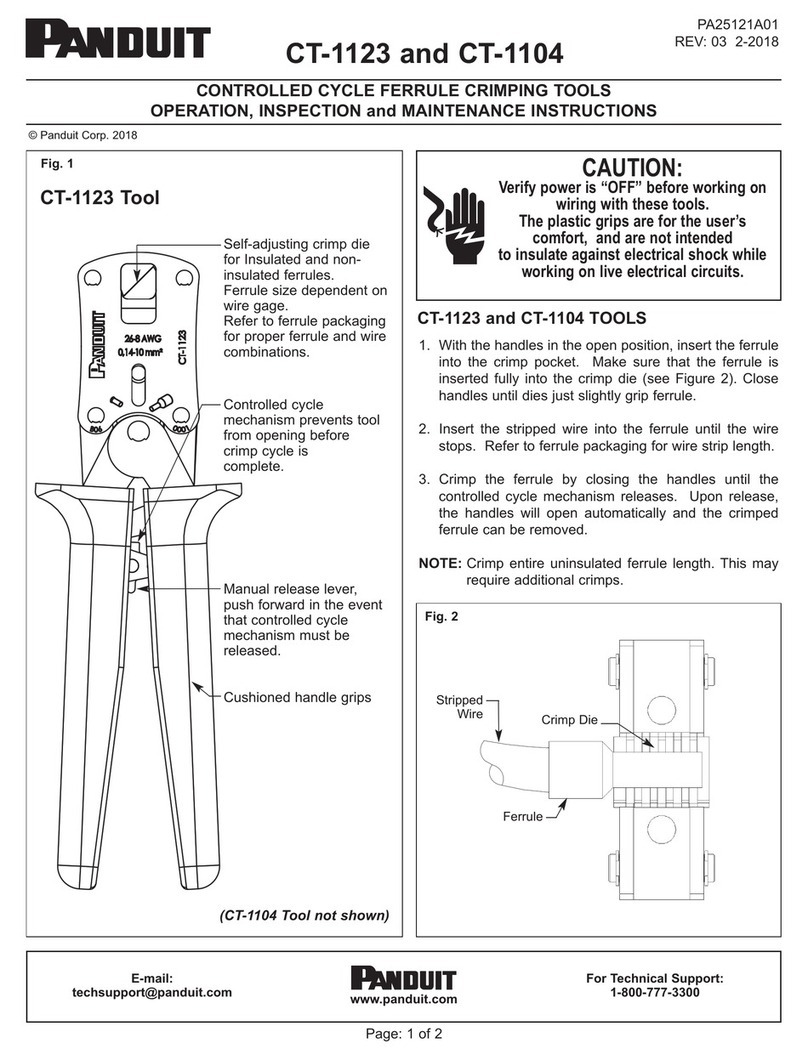

OPERA ION INS RUC IONS

© Panduit Corp. 2017