panel PMG2 Series User manual

Other panel Touchscreen manuals

panel

panel PSR1-FO Series User manual

panel

panel PVR-EM Series User manual

panel

panel PC PSR110-FM Series User manual

panel

panel PSR110-EM Series User manual

panel

panel PSR3-EM Series User manual

panel

panel PSG2-EM Series User manual

panel

panel PC PSG2-EP Series User manual

panel

panel PSR3-EK Series User manual

panel

panel PSR3-EP Series User manual

panel

panel PC PSG2-EN Series User manual

Popular Touchscreen manuals by other brands

Element

Element VK Series user manual

Johnson Controls

Johnson Controls Advanced Graphic Touchscreen Display Installation and operation manual

Elo TouchSystems

Elo TouchSystems 2799L user manual

Elo TouchSystems

Elo TouchSystems 2020L Product dimensions

Wiggly-Amps

Wiggly-Amps Engage installation instructions

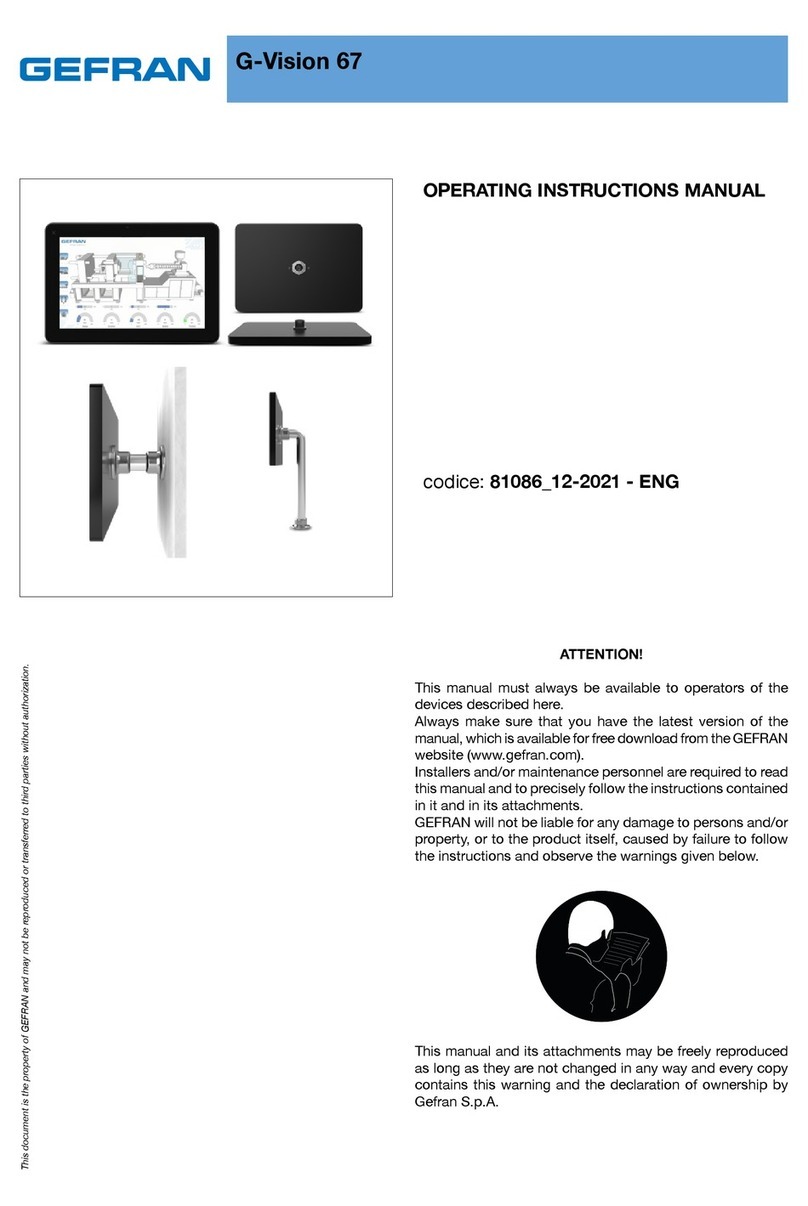

gefran

gefran G-Vision 67-070 Operating instructions manual