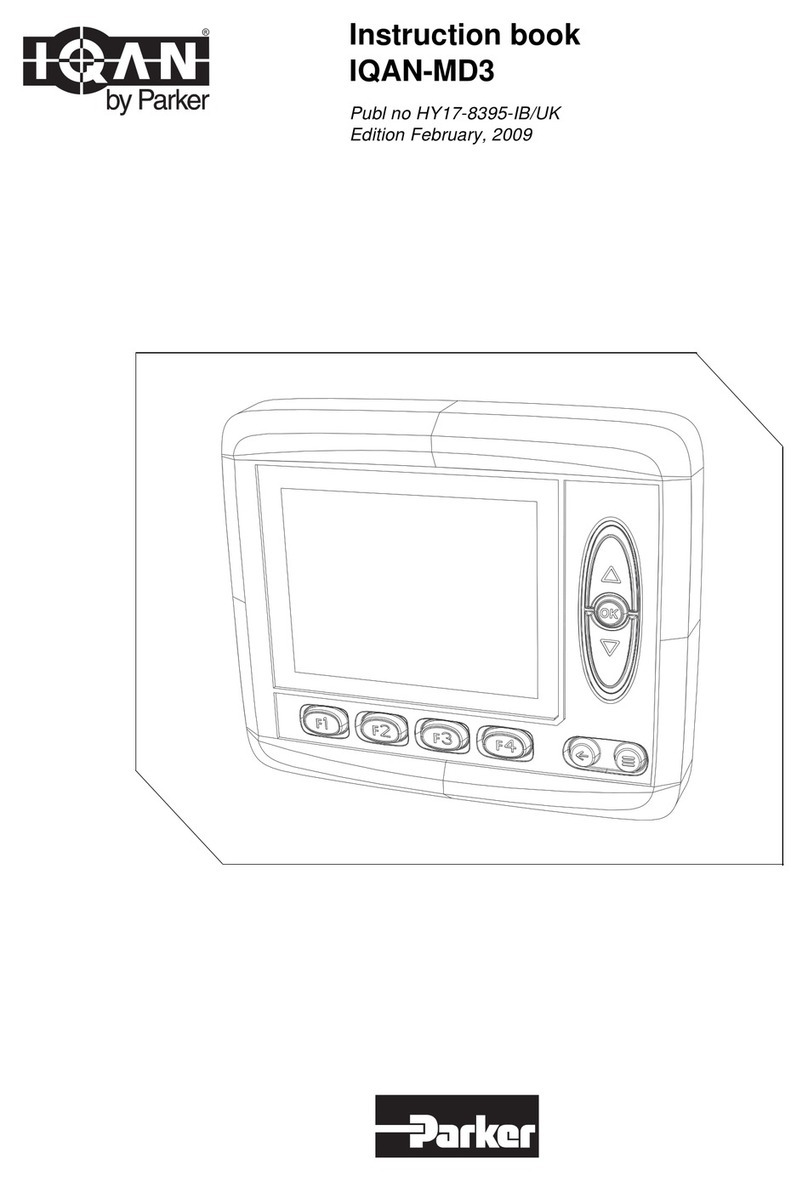

Parker Pro Display 12 Instruction Book 4/54

4.8.3. Real time clock ....................................................................................................25

4.8.4. EEPROM .............................................................................................................25

4.8.5. Diagnostic LEDs ..................................................................................................26

4.8.6. Temperature sensor ............................................................................................26

4.9. Mass storage.....................................................................................................................26

5. Software...................................................................................................................28

5.1. General .............................................................................................................................28

5.2. Parker UX Toolkit ..............................................................................................................28

5.2.1. Parker UX Platform (UXP)...................................................................................28

5.2.2. Parker Application Designer ................................................................................28

5.3. UXP Configuration ............................................................................................................28

5.4. Installing and removing applications .................................................................................29

5.5. Pro Display operation modes............................................................................................30

5.5.1. Sleep mode..........................................................................................................31

5.6. Diagnostics........................................................................................................................31

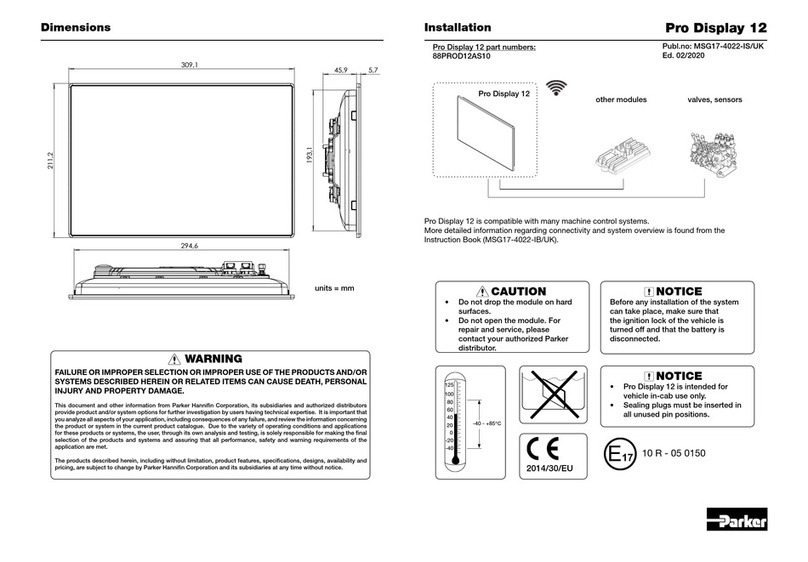

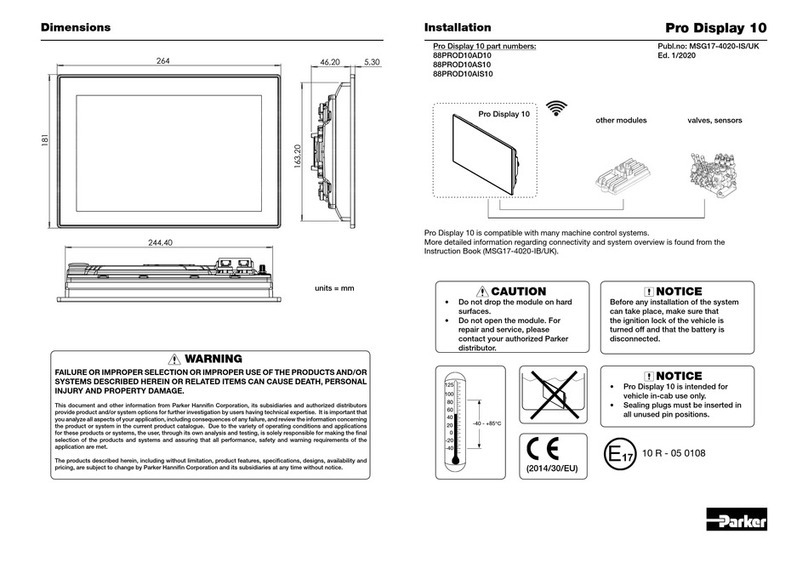

6. Mechanics................................................................................................................32

6.1. Mechanical construction ...................................................................................................32

6.2. Dimensional drawing.........................................................................................................32

7. Mounting..................................................................................................................33

7.1. Mounting the module.........................................................................................................33

7.1.1. Assembly surface conciderations ........................................................................33

7.2. Dashboard or panel assembly ..........................................................................................33

7.2.1. Panel assembly ...................................................................................................33

7.3. Ball / swivel mount ............................................................................................................34

8. Installation ...............................................................................................................37

8.1. Electrical connections .......................................................................................................37

8.1.1. Main connectors C1 and C2 ................................................................................38

8.1.2. USB connections C3 and C4...............................................................................39

8.1.3. Video connection C5 ...........................................................................................40

8.1.4. Ethernet connection C6 .......................................................................................41

8.1.5. Micro SD card interface .......................................................................................42

8.1.6. Radio antenna connection...................................................................................44

8.2. Power supply considerations ............................................................................................45

8.2.1. Supply voltage .....................................................................................................45

8.2.2. Emergency stop...................................................................................................45

8.2.3. Connecting of supply voltage ..............................................................................45

8.2.4. RTC back-up supply ............................................................................................45

8.2.5. Polarity reversal ...................................................................................................46

9. Start-up ....................................................................................................................46

9.1. Procedures with software..................................................................................................46

10. Appendix A – Technical summary .......................................................................47

11. Appendix B – Environmental summary ...............................................................49

12. Appendix C - Ordering codes ...............................................................................54