User Guide iii

Publication History ...............................................................................................................v

Safety ....................................................................................................................................vi

Safety symbols.................................................................................................................................vi

General safety regulations...............................................................................................................vi

Welding after installation.................................................................................................................vii

Construction regulations .................................................................................................................vii

Safety during installation.................................................................................................................vii

Safety during start-up.....................................................................................................................viii

Safety during maintenance and fault diagnosis.............................................................................viii

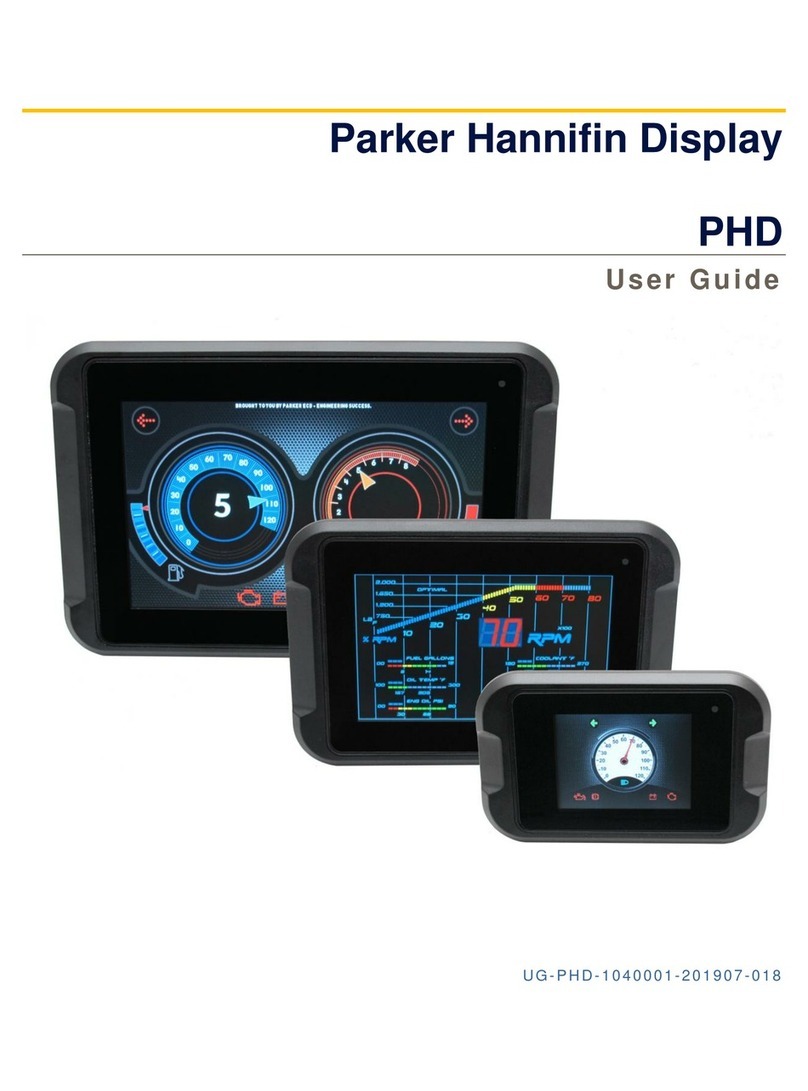

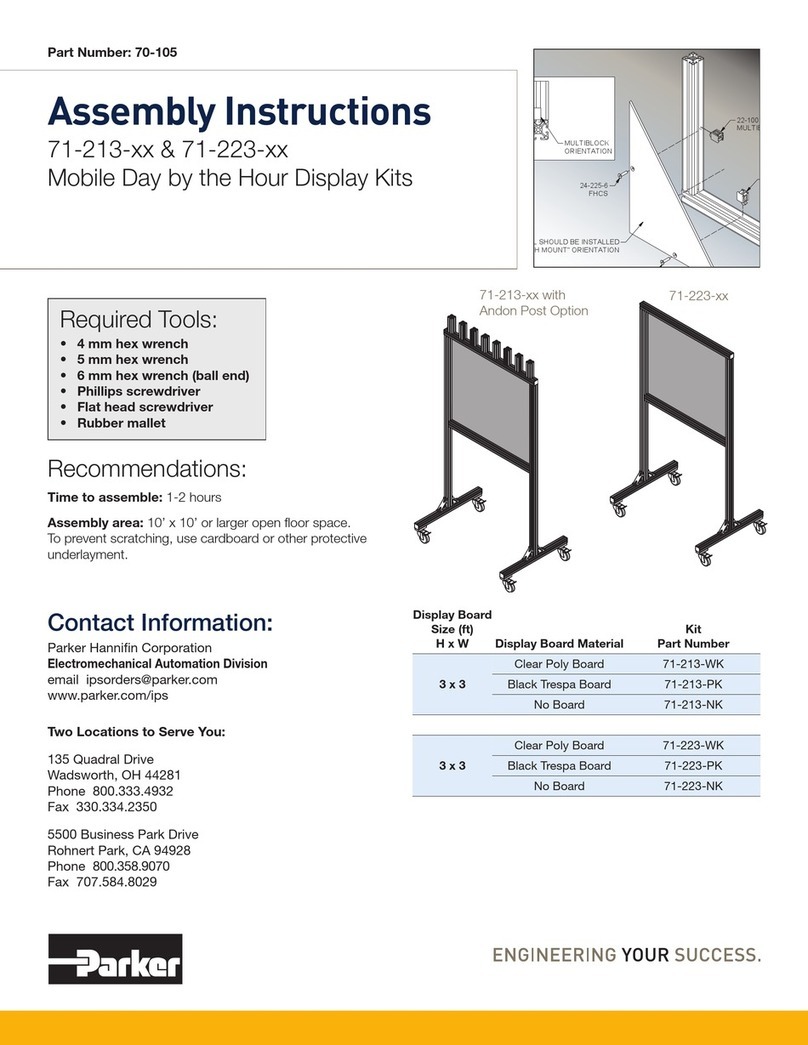

1. About the PHD (Parker Hannifin Display).......................................................................1

1.1. Diagram conventions ................................................................................................................4

2. Connectors........................................................................................................................6

2.1. Pinouts......................................................................................................................................7

3. Inputs ...............................................................................................................................12

3.1. PHD28 inputs..........................................................................................................................12

3.2. PHD50 inputs..........................................................................................................................13

3.3. PHD70 inputs..........................................................................................................................14

3.3.1. PHD28/PHD50 analog input capabilities...................................................................14

3.3.2. PHD28/PHD50/PHD70 digital input capabilities........................................................17

3.3.3. PHD50/PHD70 frequency input capabilities..............................................................18

3.4. Using inputs as low power outputs.........................................................................................20

3.4.1. Low power, high-side output capabilities...................................................................21

4. Outputs ............................................................................................................................23

4.1. Low-side outputs.....................................................................................................................23

4.1.1. Low-side output capabilities ......................................................................................23

4.2. Sensor and regulated supply outputs .....................................................................................25

4.2.1. Sensor and regulated supply capabilities..................................................................26

5. Power ...............................................................................................................................27

6. Communication...............................................................................................................28

6.1. Controller Area Network..........................................................................................................28

6.1.1. CAN capabilities ........................................................................................................28

6.1.2. J1939 CAN Installation Connections.........................................................................29