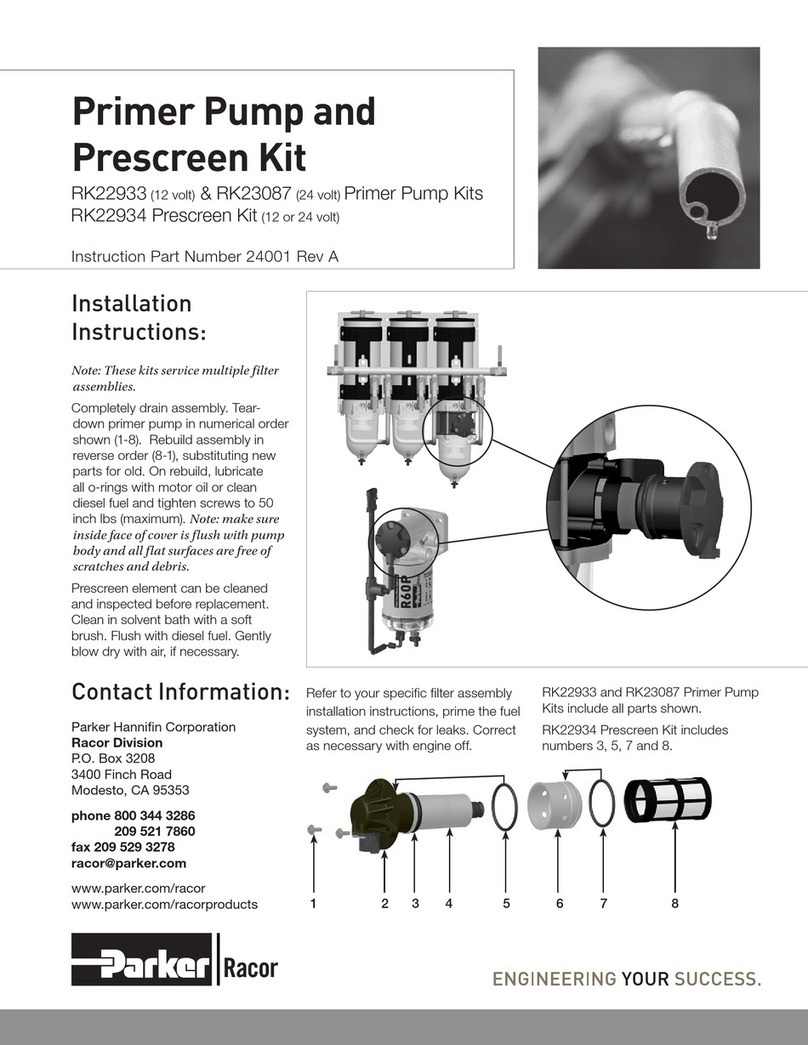

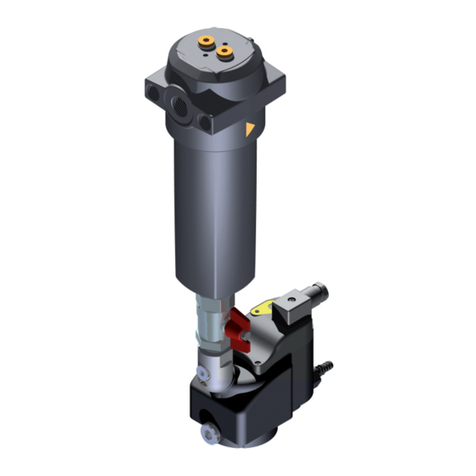

Refer to Mounting Instructions

and Installation Diagram and

install as follows:

Make sure engine is off and1.

cool to touch.

445R, 460R and 490R: Apply2.

thread sealant to NPT fittings

(do not use thread tapes

as particles may break off

and contribute to clogging

element). 4120R: Apply motor

oil or diesel fuel to O-ring on

UNF fittings.

Thread fittings into3.

appropriate fuel ports and

tighten snugly. Plug unused

ports (if any) with port plugs

and tighten snugly.

Mount filter vertically in a4.

protected area and away from

heat sources. Maintain at least

2.0” (5.1 cm) of clearance

below filter for draining water

and servicing element.

Attach fuel lines to filter.5.

Avoid tight bends and rubbing

areas when routing hose.

Connect water probe and6.

heater wires (if equipped).

Open vent plug and operate7.

hand primer pump until fuel

purges from vent.

Close vent plug and start8.

engine. Correct as necessary

with engine off.

Installation

Guidelines

Service

Element replacement frequency

is determined by contamination

level in fuels. Fuel flow to

engine becomes restricted as

element gradually plugs with

contaminants, resulting in

noticeable power loss and/or

hard starting. As a guideline,

change element every 500

hours, 10,000 miles, every

other oil change, annually,

or at first indication of power

loss, whichever occurs first.

Always carry extra replacement

elements as one tankful of

excessively dirty fuel can quickly

plug a filter.

Make sure engine is off and

1.

cool to touch.

Close all fuel valves, if2.

applicable, to make sure

excess fuel does dot spill

during servicing.

Disconnect water probe3.

and heater connectors,

if equipped.

Open vent plug on4.

mounting head.

Drain unit of fuel.5.

Remove bowl and element.6.

Dispose of element properly.

Bowl is reusable.

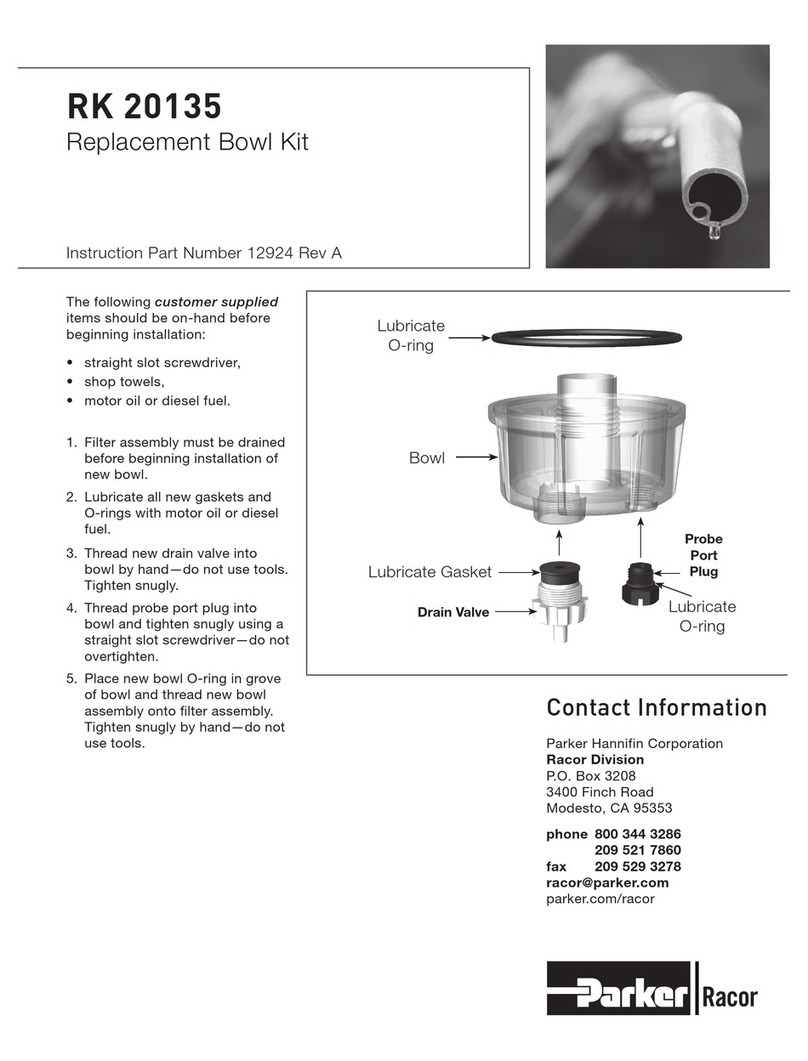

Lubricate new element7.

seals with motor oil or clean

fuel and install only with

new element.

Re-install bowl and tighten by8.

hand only - do not use tools.

Connect water probe9.

and heater connectors,

if equipped.

Open all fuel valves,10.

if applicable.

Operate hand primer pump11.

until fuel purges from vent.

Close vent plug and start12.

engine. Correct as necessary

with engine off.

Draining the

Collection Bowl

Water is heavier than fuel and

will settle to bottom of bowl

and appear different in color if

collected in a clear jar. In high

humidity environments, check

bowl frequently (daily if a poor

fuel source is suspected). 400

Series bowls are equipped with a

water sensor port that will accept

a water probe (sold separately)

and will alert operator of a high

water condition in the filter.

Do NOT use water probe

electronics in gasoline

applications - an explosion

could occur.

Make sure engine is off and1.

cool to touch.

Open vent plug.2.

Drain water from filter by3.

opening self-venting drain.

Close as soon as all water

has evacuated.

If drain is open too long, the

entire filter may drain completely

of water and fuel.

Follow priming instructions.4.

Priming

Prime filter by operating hand1.

primer pump until fuel spills

out of vent port.

Close vent plug snugly.2.

Verify all other connections3.

are tight.

Start engine and check for4.

leaks. Correct as necessary

with engine off.

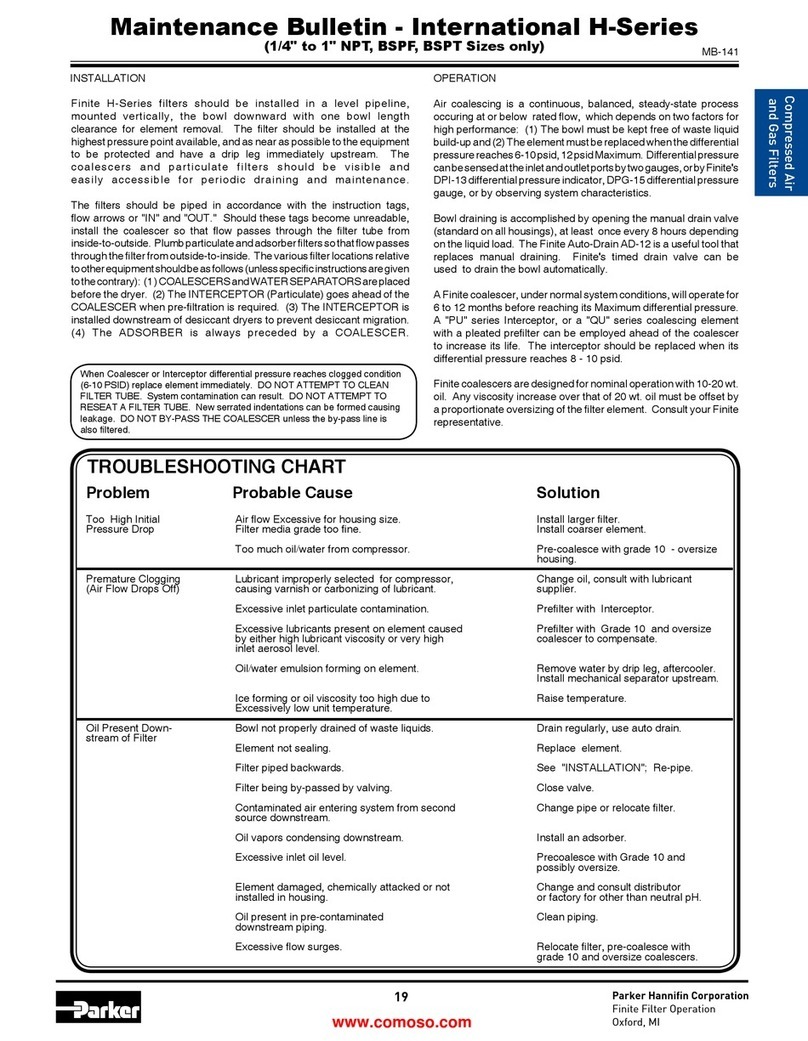

Trouble Shooting

If filter fails to hold prime, first

check vent plug, drain valve,

fittings, head, element, and bowl

are properly tightened. Next,

check fuel line connections and

verify they are free of pinches or

unnecessary bends and check to

see if fuel tank strainer (or pick-

up tube) is clogged. If problems

persist and element is new,

call Racor Technical Support

at 800-344-3286, 8 AM to 5 PM,

Pacific Standard Time.