C o n f i d e n t i a l P a r k e r S e a R e c o v e r y 0 6 1 2 2 0 1 7

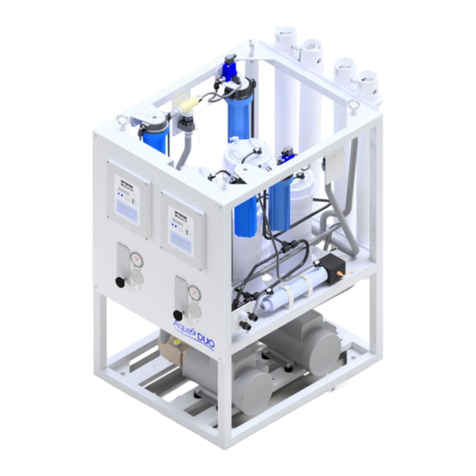

Service and maintenance for the RO system depends upon many factors such as the source water

type, quality, frequency of operation, hours of operation per day, ambient conditions, and overall

installation. Regular maintenace is required in order to keep the ULTROclear Z series RO

system operating efficiently. The table below provides GENERAL guidelines for maintaning the

RO system.

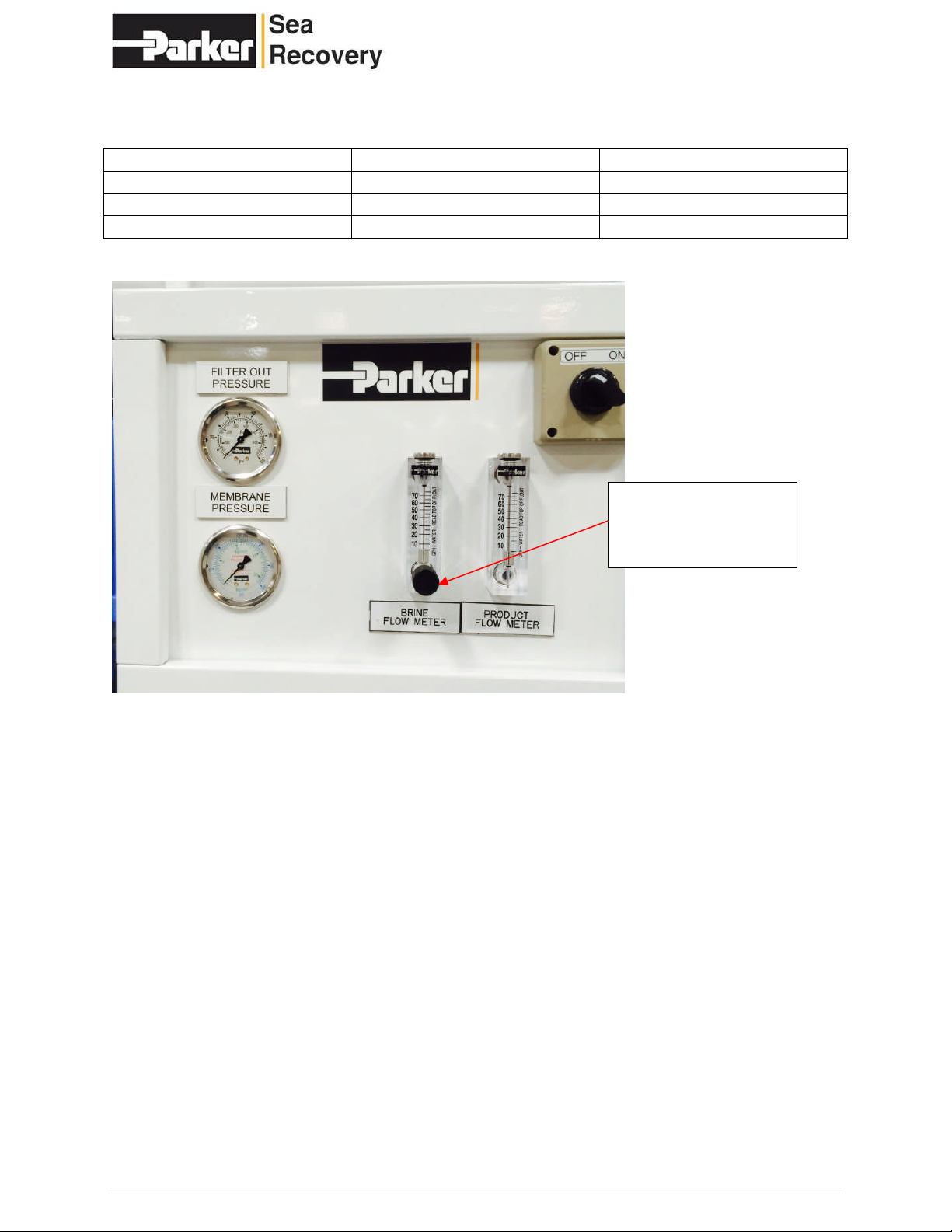

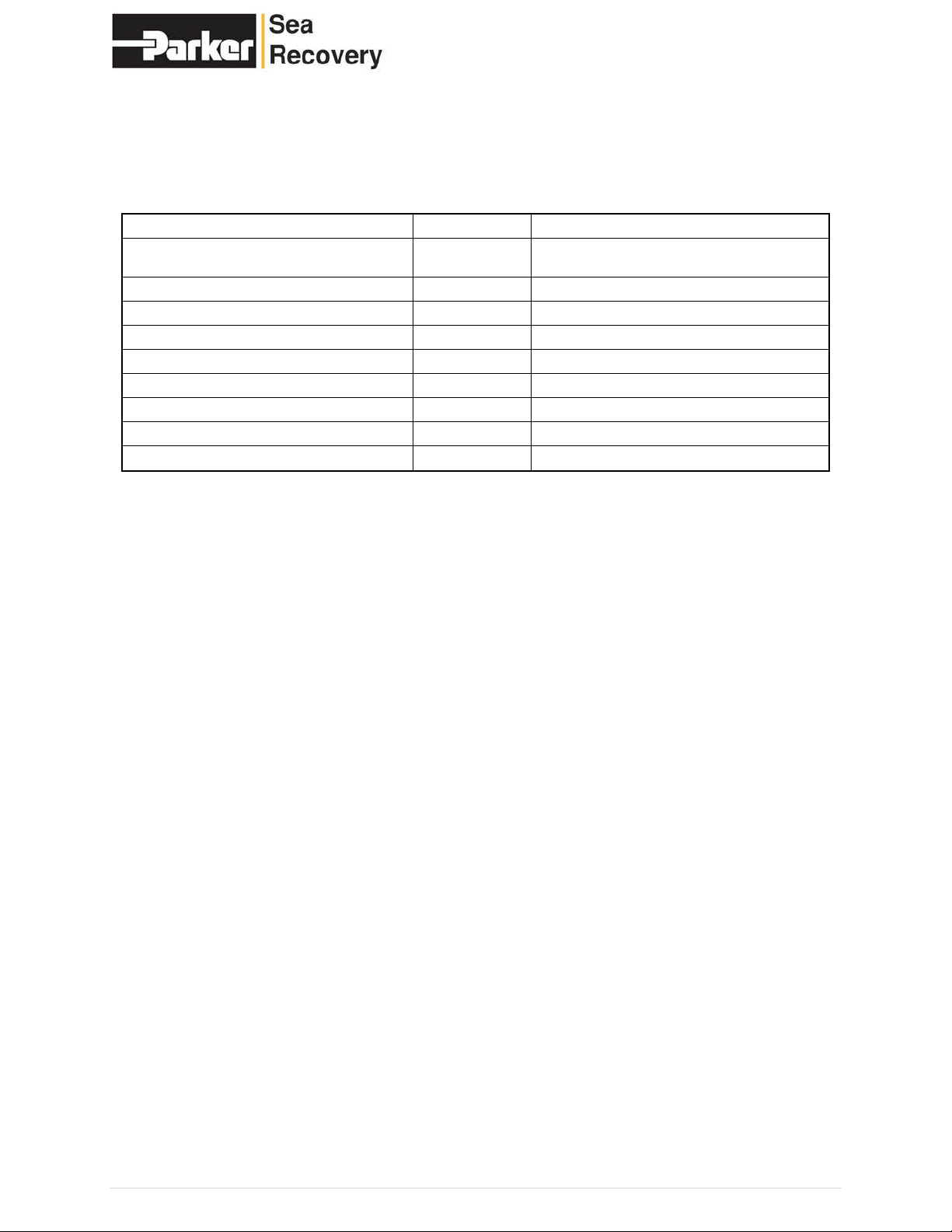

Description Frequency Other /notes

Clean RO membranes 1-4 months

depending upon water quality and

operations

Record keeping and system monitoring Daily recorded with photos

Replace cartridge filters Monthly more frequently with higher DP

Replace carbon cartridge filters 2-4 weeks ORP to RO to be < 300mV

Replace pH neutralizing cartridge 1-2x/month monitor pH, replace if < 7.5-8

Flush RO membranes as req'd when not operating for more than 2-7 days

RO membrane replacement 1-5 years depending upon operations & cleaning

Replace carbon pretreat tank media 6-18 months monitor ORP daily

Replace media in prefilter MMF 1-4 years relating to source water turbidity/quality

Note: System warranty requires the use of only Parker Hannifin/Water Purification spares,

consumables, chemicals, components and appurtenances. Use of any other products or

equipment voids all warranty for the system. Daily operational information for all pressure,

flow, and conductivity in the system is required to be provided in the case of any warranty

claims. Pressure, flows, and conductivity must be provided for each flow stream with daily

recordings, photos and documentation.

ULTROclear (DF) System Cleaning

The ULTROclear DF RO system should be cleaned when the membrane pressure is observed to

increase by approximately 10-15% or at least once every 2-6 months. Cleaning involves

introducing Parker cleaning chemicals onto the membranes, soaking, and flushing the chemicals

out of the system. Cleaning always involves flushing the ULTROclear unit with clean

dechlorinated fresh water (or permeate) followed by the use of cleaner 1 and then cleaner 2.

1. Record all current flows, pressure and permeate conductivity for the system

2. Stop the UC system and flush the unit with dechlorinated fresh water or permeate with

the brine control black knob fully open, counterclockwise.

3. Turn the system off, open the downstream prefilter housing AC-20B and remove the

carbon/sediment prefilter.

4. Install cleaner 1, into the AC-20B housing

5. Remove the carbon/sediment filter from AC-20A and install a new carbon/sediment filter

6. Using fresh water feeding the system, turn the UC unit ON with the black brine control

knob fully open and flush the unit with cleaning chemical for approximately 5 minutes

7. Route the brine and product lines to drain

8. Stop the UC system and allow the chemical 1 solution to soak on the membranes for 5 to

60 minutes (longer soaks for more heavily fouled membranes)