Always follow your engine

manufacturer’s guidelines for

priming the fuel system. To prime

the filter:

1. Spin bowl and filter off of

mounting head (together).

2. Fill filter with clean fuel.

3. Apply a coat of motor oil or

clean fuel to filter gasket.

4. Spin bowl and filter (together)

onto mounting head tighten by

hand—do not use tools.

5. Start engine and check for

leaks. Correct as necessary with

engine off.

Draining The Bowl

Water is heavier than fuel and

will settle to bottom of bowl and

appear different in color. In high

humidity environments, check

bowl frequently (daily if a poor fuel

source is suspected).

1. Make sure engine is off and

cool to touch.

2. Close shut-off valve between

fuel tank and filter, if applicable.

3. Open vent plug on mounting

head.

4. Slowly open drain on bottom

of collection bowl and allow

only water to drain out—do not

leave drain open for very long

as it will eventually drain the

entire filter of all water and fuel.

5. When fuel is detected coming

out of drain, close drain quickly

and tighten snugly.

6. Close vent plug and tighten

snugly.

7. Open Shut-off valve if

applicable.

8. Follow Priming instructions.

Danger! Great care must be

exercised to avoid potential fire

hazards during installations. Do

not smoke or permit open flames

or sparks near the fuel system.

Refer to Installation Diagram

on page 4 prior to beginning

installation.

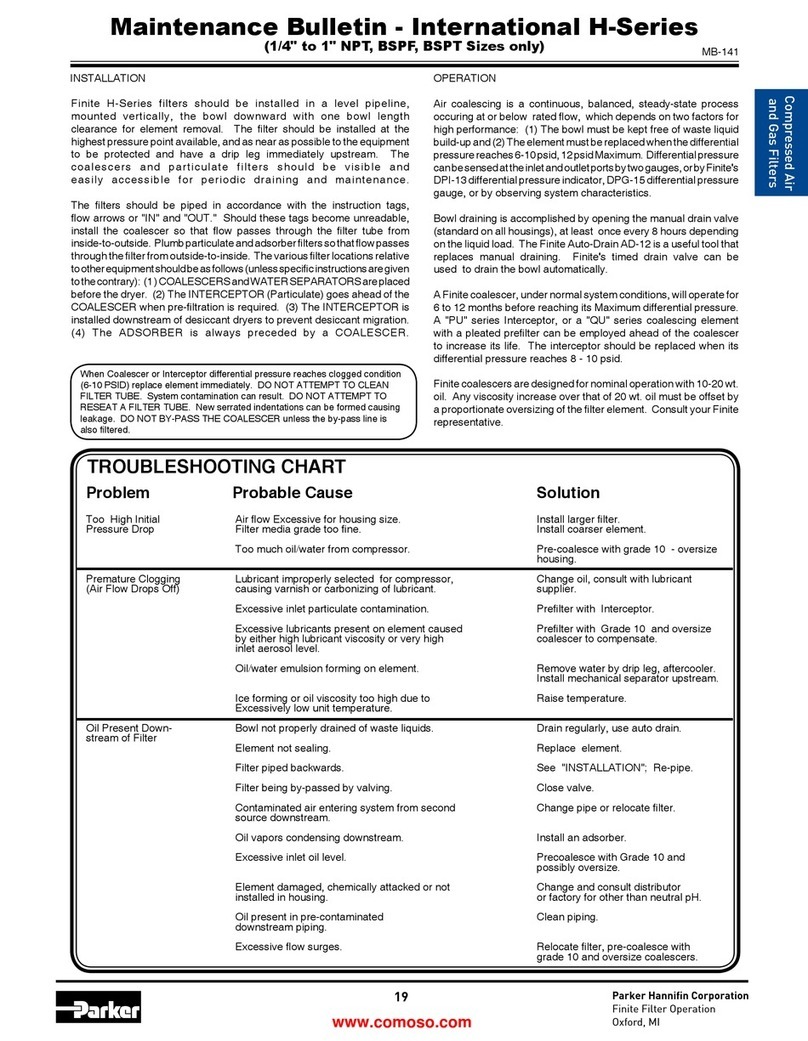

• Any secondary or pressure side

filters located between pump

and engine should be serviced

and left in place.

• Mount unit vertically on suction

side of fuel pump, transfer

pump, or non-removable filters,

whichever comes first.

• Maintain 2” (5.1 cm) vertical

clearance below lter for servicing

bowl and replacing lter.

• Ensure a suitable pipe thread

sealing compound is used on

NPT threads of tting prior

to installation into head. For

mounting exibility, there are

two inlet ports and two outlet

port. Plated steel ttings are

recommended. Plug unused ports

with provided steel NPT plugs—do

not use tapes on NPT threads.

• Use quality fuel hose in

maximum fuel line size

applicable to reduce potential

fuel flow restrictions. Note:

USCG accepted hose

recommended.

• Thread fittings into appropriate

fuel ports and tighten snugly.

Plug unused ports (if any) with

port plugs and tighten snugly.

• Attach fuel lines to filter. Avoid

tight bends, rubbing areas and

heat sources when routing hose.

• Follow Priming Instructions.

Installation Guidelines

Service

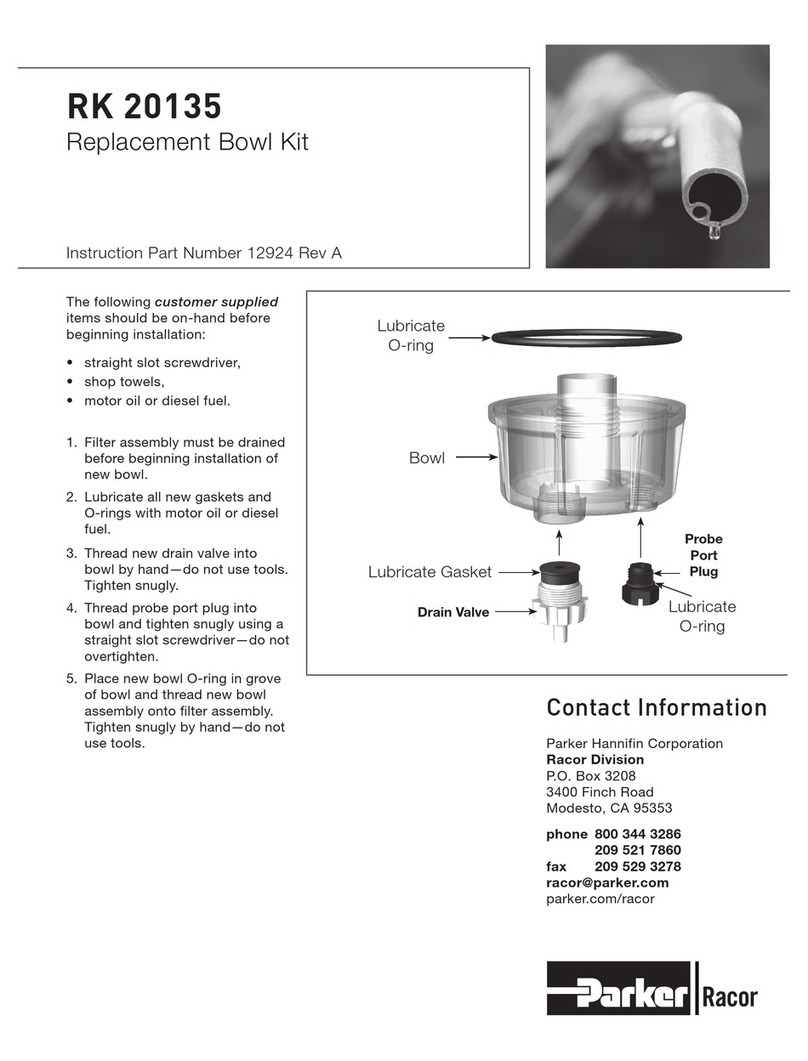

Filter Replacement

Filter replacement frequency is

determined by contamination

level in fuels. Fuel flow to engine

becomes restricted as filter

gradually plugs with contaminants,

resulting in noticeable power

loss and/or hard starting. As a

guideline, change filter every 500

hours, every other oil change,

annually, or at first indication of

power loss, whichever occurs first.

Always carry extra replacement

filters as one tankful of excessively

dirty fuel can quickly plug a filter.

1. Clean all debris or dirt away

from head of filter assembly

prior to servicing.

2. Place a container of sufficient

volume below filter assembly

to collect contaminants.

3. Close tank outlet valve if tank

is mounted higher than filter, if

equipped.

4. Open drain (remove plug on

-02 model) to empty filter

assembly of fuel.

5. Spin filter and bowl off

together, then remove bowl

from filter.

6. Dispose of filter properly.

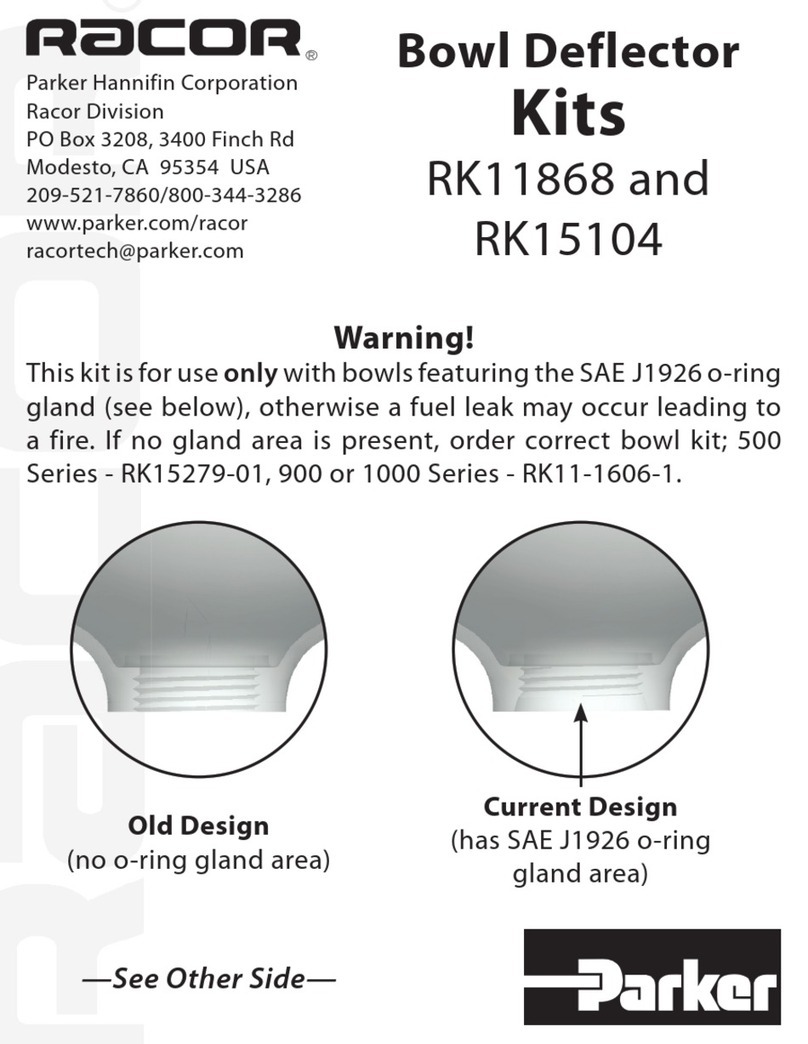

7. Clean bowl O-ring gland and

sealing surface of mounting

head free of dirt, debris, or

gums.

8. Apply motor oil to new filter

seal and bowl O-ring (supplied

with new filter).

9. Place filter seal onto filter and

O-ring into bowl gland.

10. Spin bowl onto new filter

snugly by hand—do not use

tools.

11. Priming fuel system following

your manufacturer’s

procedures, if necessary;

otherwise, see Priming

section.

Priming