176

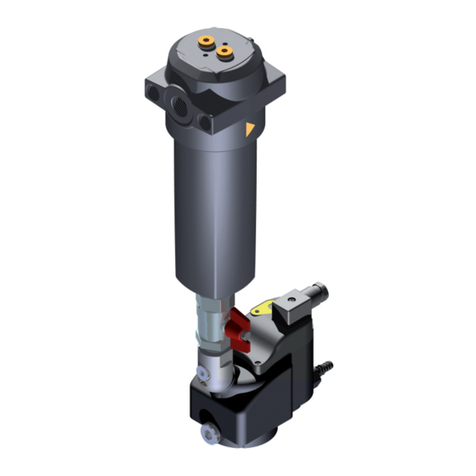

Assembly

1) Install hoses to inlet and outlet

filters by threading the hose end

with the straight thread “o”-ring

seal fitting into the filter flange.

2) Connect the PVC tube wands to

the swivel fitting on the hose end.

Whenever servicing the PVC tube

wand do not overtorque the metal

fittings going into the PVC coupling.

Overtorque will result in cracking the

coupling. Generally, 1/4 turn beyond

handtight is sufficient.

Operating Instructions

1) Insert the inlet wand assembly

into the supply fluid receptacle

(drum/reservoir). The “RF”. filter

is the inlet filter.

2) Insert the outlet wand assembly

into the clean fluid receptacle

(drum/reservoir). The “CF” fIlter

is the outlet filter.

Caution:

Do not kink the hose assemblies,

this may result in excessive

vacuum or pressure at the pump.

3) Verify that the ON/OFF switch is

OFF and plug the cord into a 115V

10A grounded outlet (3 wire).

4) Turn switch to ON position and

check outlet wand for oil flow.

Allow 30 to 60 seconds for filters

to fill with oil. If repeated attempts

to obtain oil flow fail, check pump

inlet fittings for tightness, remove

inlet filter access cover and verify

the cover sealing “o”-ring is in

place. For very viscous fluids it

may be necessary to pour 1 or 2

quarts of fluid into the “RF” inlet

filter housing to prime pump

initially.

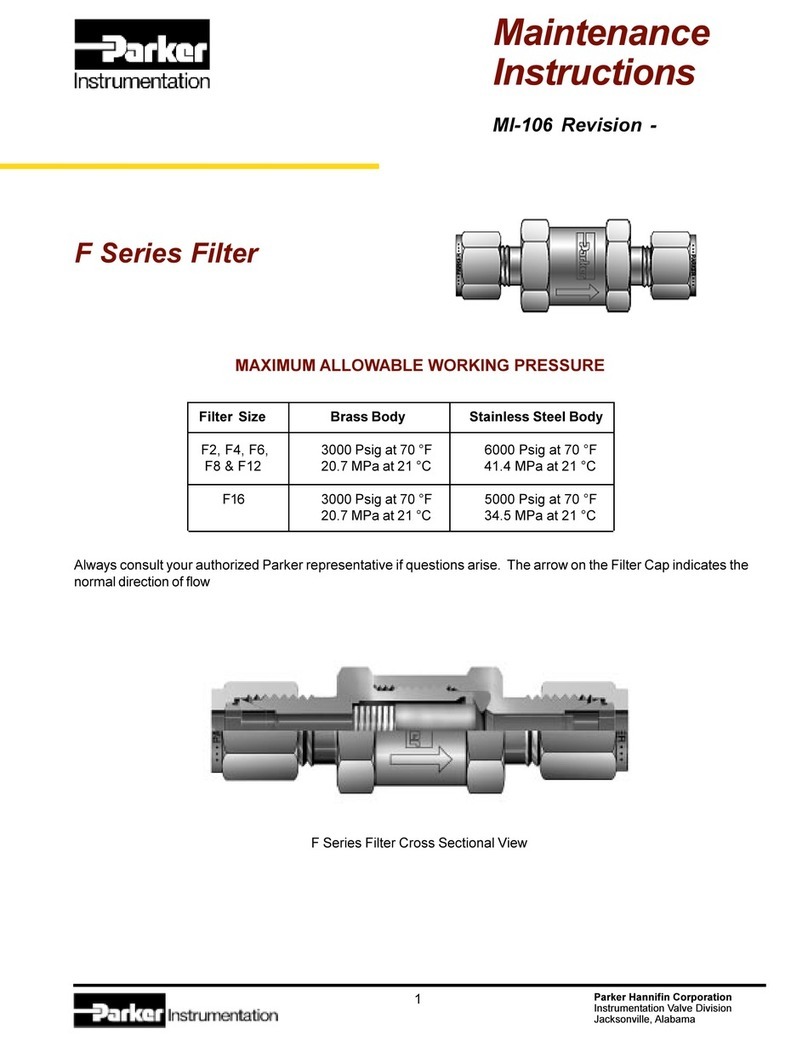

5) The condition of the filter

element should be monitored by

observing the cleanliness

indicator on the discharge

filter. When the Indicator is in the

CHANGE position, both inlet and

outlet filter elements MUST be

replaced to prevent fluid from

going into bypass in the filters.

6) The inlet filter Is provided with a

3PSI bypass spring, and prevents

the pump from cavitating If the

element is not changed. The outlet

filter is provided with a 25PSl

bypass spring to prevent excessive

pressure which may be harmful to

personnel or to the filter cart.

Warning:

The filter bypass spring acts as a

relief valve for the pump. Do not

restrict the discharge hose with

a shut-off valve which will defeat

the function of the bypass valve,

causing excessive pressure, which

may be harmful to personnel or to

the filter cart.

7) The cleanliness indicator works

on differential pressure and

will indicate the condition of the

element (CLEAN, CHANGE, or

BYPASS).

NOTE:

The filter cart must be in

operation for the indicator

to read properly.

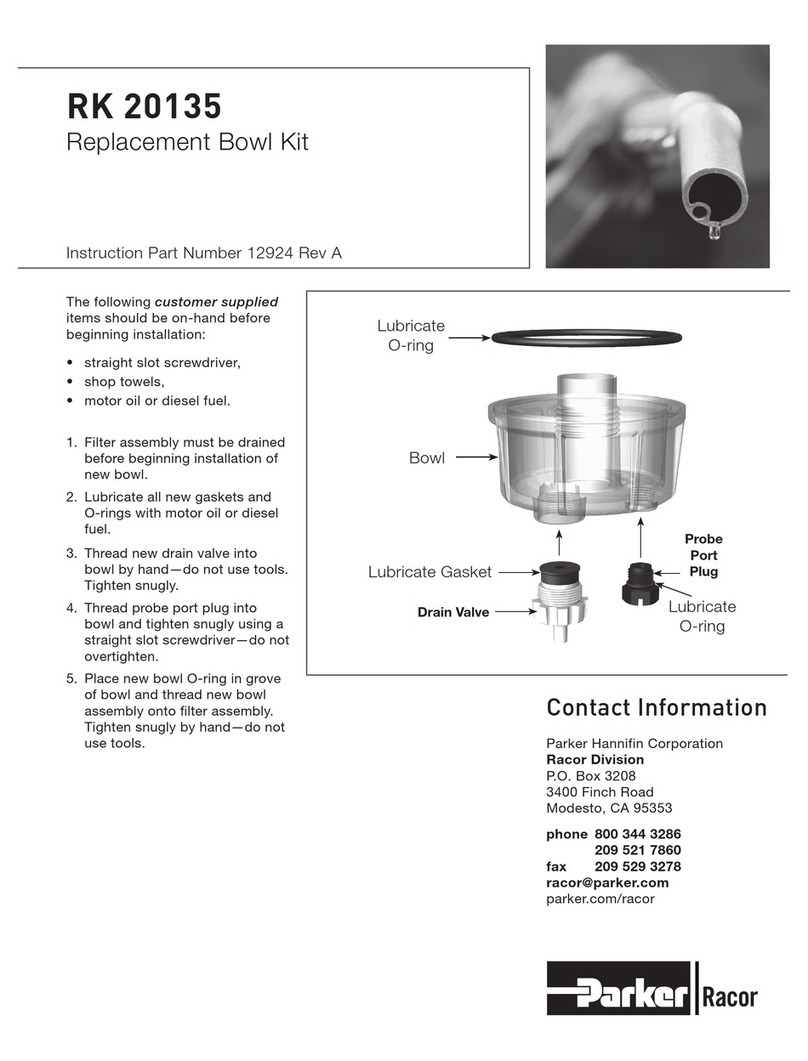

Maintenance

Instructions

1) Turn switch to OFF position and

unplug cord from electrical outlet.

2) Remove tube wands from oil to

prevent siphoning.

3) Loosen hex head screws on

filter cover. Turn cover to clear

screws, remove cover.

4) Pull flow diverter assembly

from the filter head. Filter

element will follow the diverter.

a) Replace the cellulose,

synthetic or Microglass II

elements. Verify replacement.

b) Wire mesh elements can be

cleaned. Ultrasonic cleaners

provide best results.

5) Install element on flow diverter

and reinstall in filter housing.

Make sure diverter “o”-rings seat

properly into the head.

6) Check to be sure that the notch

on the flow diverter lines up with

the notch in the head.

7) Inspect the cover “o”-ring and

replace if necessary.

8) Replace cover and tighten hex

head screws until they are snug.

Do not over-torque these screws.

Do not interchange the inlet filter

cover with the outlet filter cover.

(The inlet filter has a “RF” prefix,

the outlet filter has a “CF” prefix).

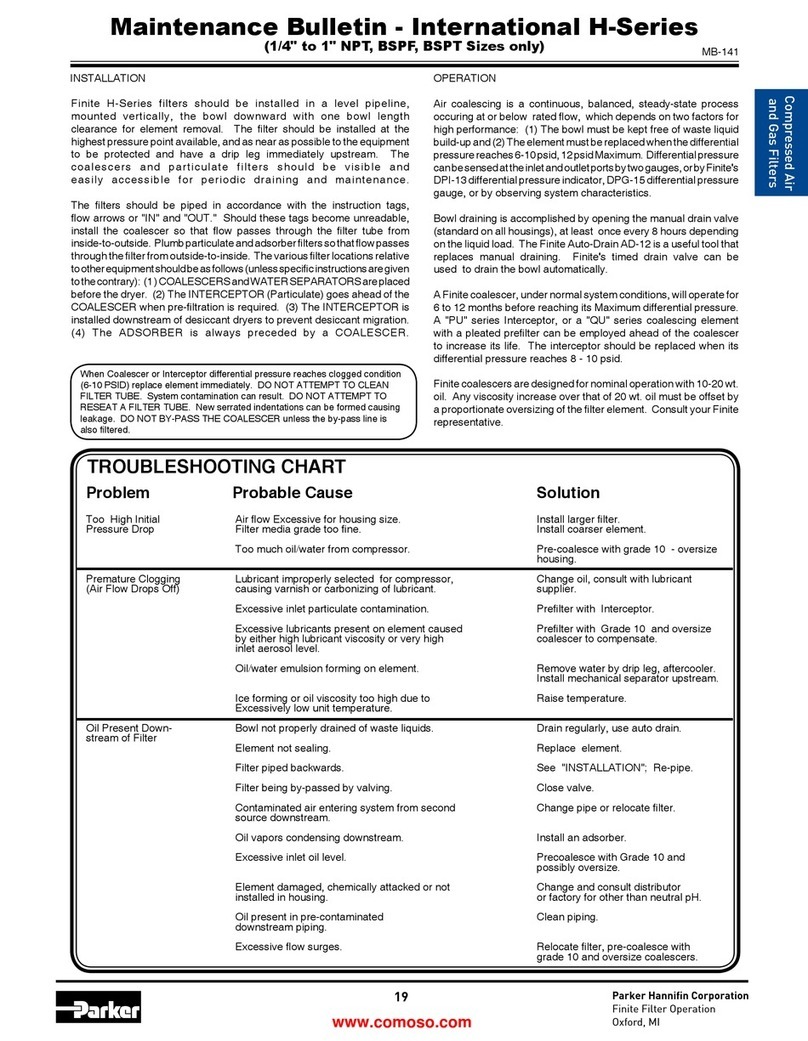

Problem Cause Solution

Does not start. ON/OFF switch. Turn switch ON, replace switch if defective.

No electrical power. Plug in cart.

Defective motor. Replace.

Filter housing not filled with oil. Allow pump to run 30 to 60 seconds.

Suction leak. Check tightness of inlet fittings.

Check “o”-ring in inlet filter cover for nicks.

Kink or restriction in inlet hose.

Add 1 or 2 quarts of oil to inlet filter.

Defective pump. Replace pump.

Element dirty.

Replace or clean elements (both filters).

Oil extremely cold or viscous. Change element to coarser micron rating.

or BYPASS.

No outlet element. Install element.

40 micron element installed

Check cart model number to verify correct

in outlet filler. element. The inlet filter has a rating “RF”

prefix; the ouflet filter has a “CF” preflx.

Trouble Shooting

No oil flow or

erratic pump noise.

Indicator does not

seem to move.

Indicator reads

CHANGE