PARRY PGF600G Instruction sheet

Other PARRY Commercial Food Equipment manuals

PARRY

PARRY GBM2W Instruction sheet

PARRY

PARRY CPC Instruction sheet

PARRY

PARRY CPC User manual

PARRY

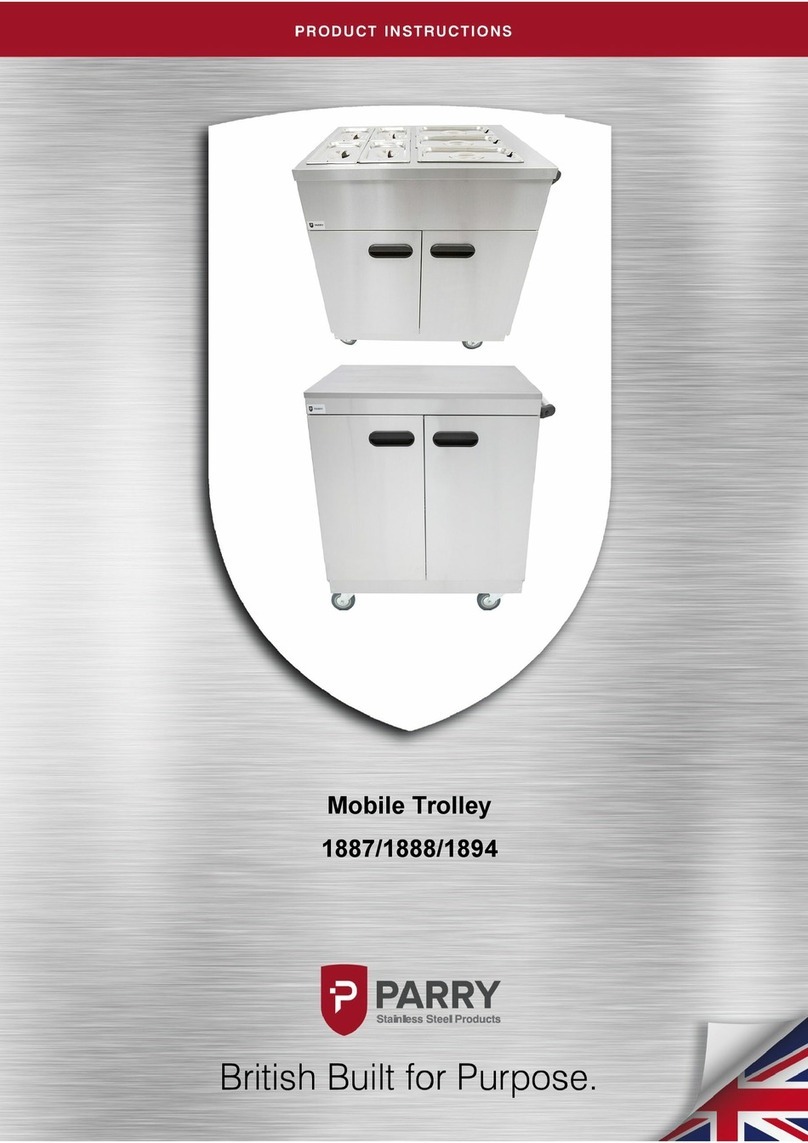

PARRY 1887 User manual

PARRY

PARRY HOT12 Instruction sheet

PARRY

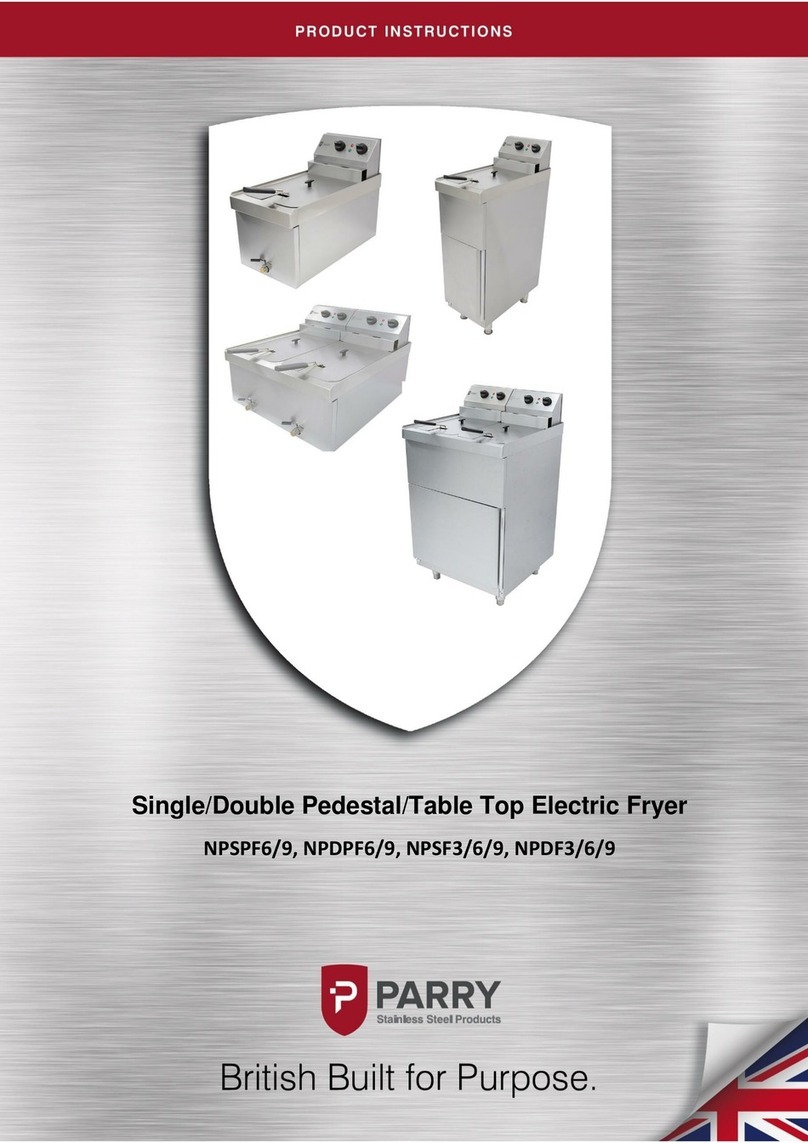

PARRY NPSPF6 User manual

PARRY

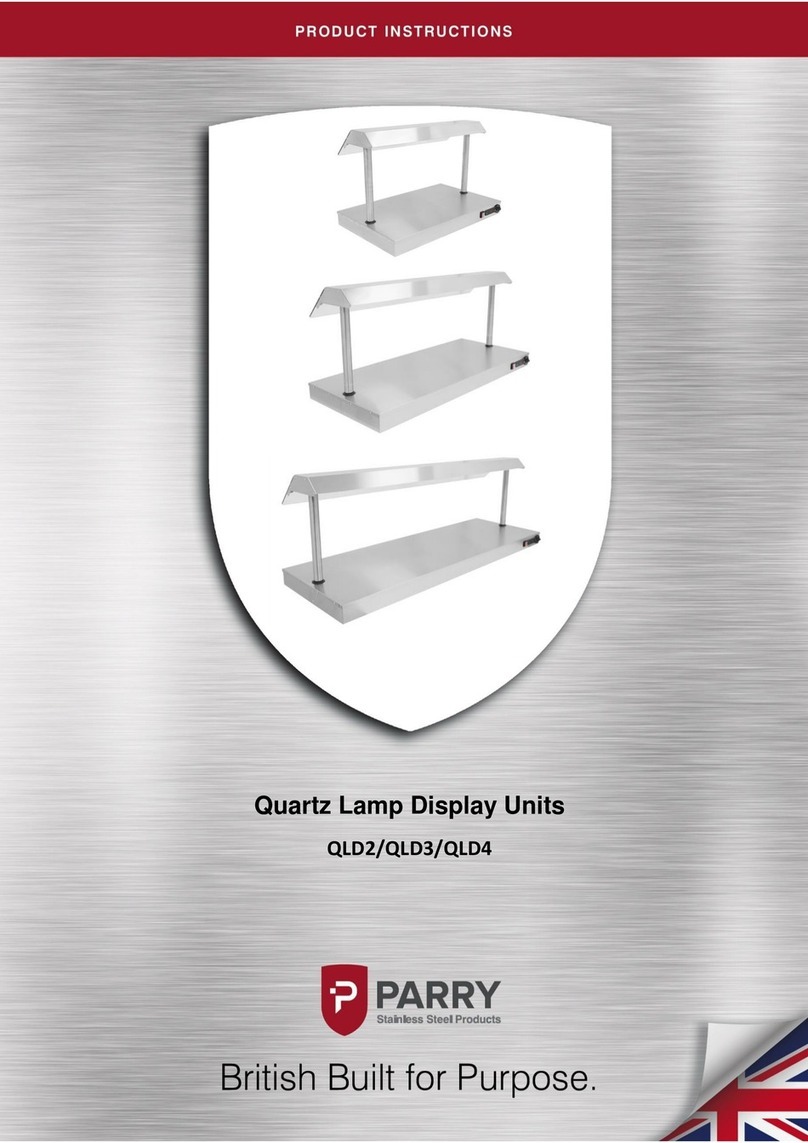

PARRY QLD2 Instruction sheet

PARRY

PARRY MSF9 Instruction sheet

PARRY

PARRY AITT1875-IFR Instruction sheet

PARRY

PARRY 1894 Installation instructions

Popular Commercial Food Equipment manuals by other brands

Blue Seal

Blue Seal EF30 Installation & operation manual

Tecfrigo

Tecfrigo Snelle 400 GS installation instructions

Follett

Follett PFT Series Operation and maintenance manual

MEFE

MEFE CAT 206 PTR User manual and maintenance

Premier

Premier 900cl Product manua

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Cambro

Cambro IBSD37 Setup guide and user manual