Materials Testing Machine Introduction

2012-13762C

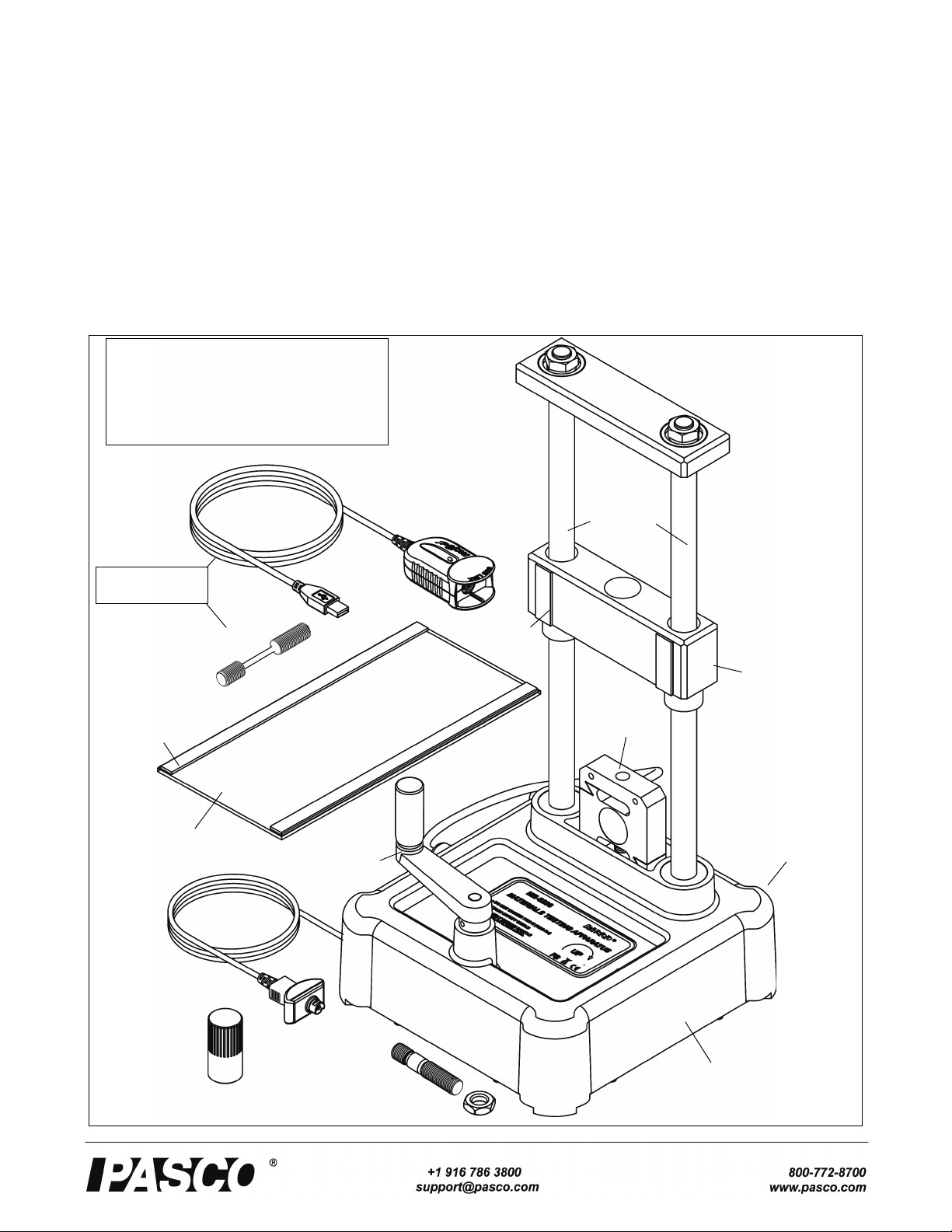

Materials Testing Machine (ME-8236)

.

*See the PASCO catalog or web site at

WWW.PASCO.COM

Materials Testing System (ME-8230)

.

Accessories and Other Items

.

.

*AP-8217A Replacement Test Coupons (Full Set) con-

sists of the AP-8222 Plastic Coupons and the AP-8223

Metal Coupons.

Introduction

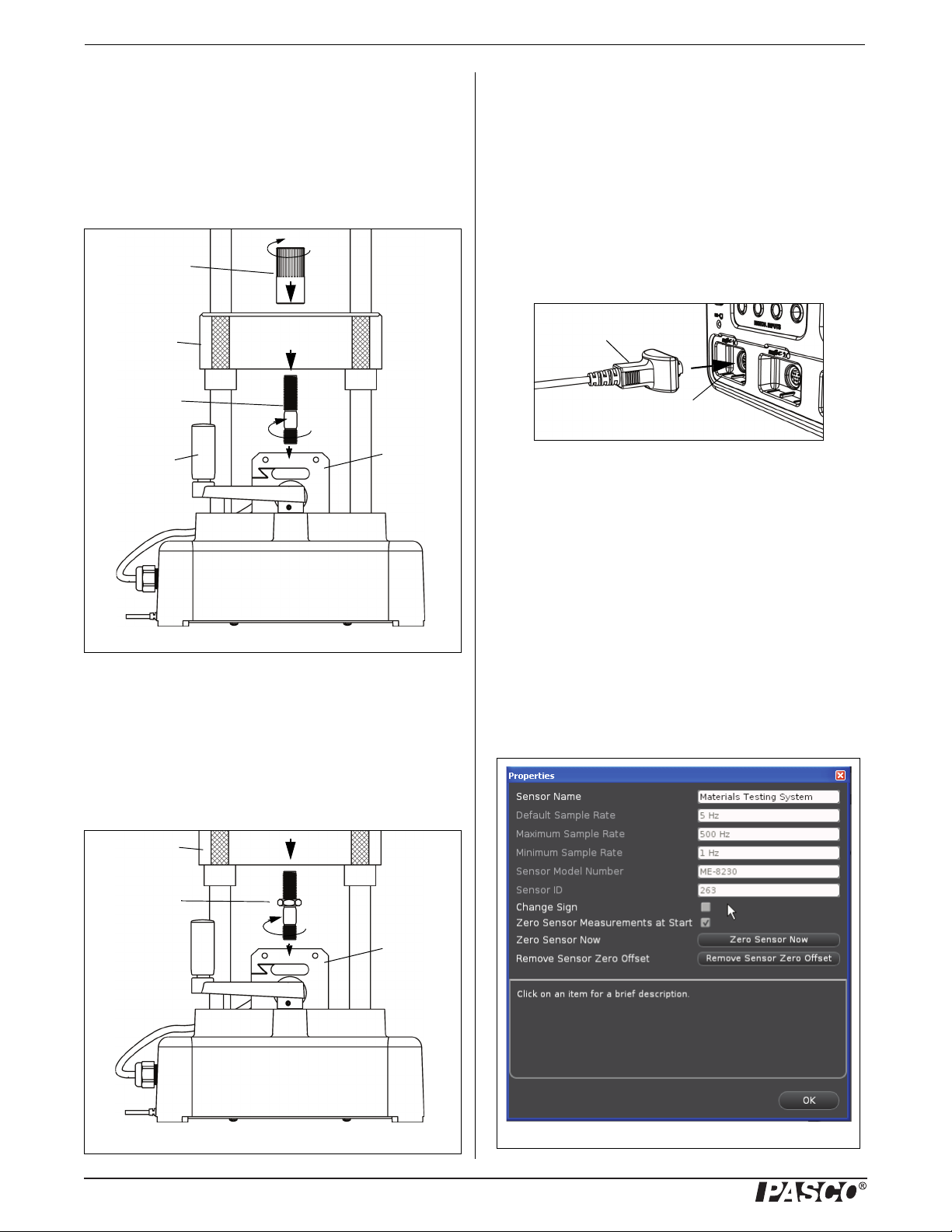

The PASCO Materials Testing Machine is a device for mea-

suring force and displacement for various materials as the

materials are stretched, compressed, sheared, or bent. The

Materials Testing Machine has a built-in load cell (strain

gauge transducer) capable of measuring up to 7100 newtons

(N) of force (1600 pounds), and an optical encoder module

that measures displacement of the load bar. A crank-and-gear

system raises or lowers the load bar on two leadscrews (also

known as power screws or translation screws). Force data

from the load cell and displacement data from the encoder

module can be recorded, displayed, and analyzed by a

PASCO Interface with PASCO Data Acquisition Software.

The sensor cable from the Materials Testing Machine con-

nects to a PASPORT input port. (See the PASCO catalog or

web site at www.pasco.com for more information about

PASCO interfaces and data acquisition software.)

Included Equipment

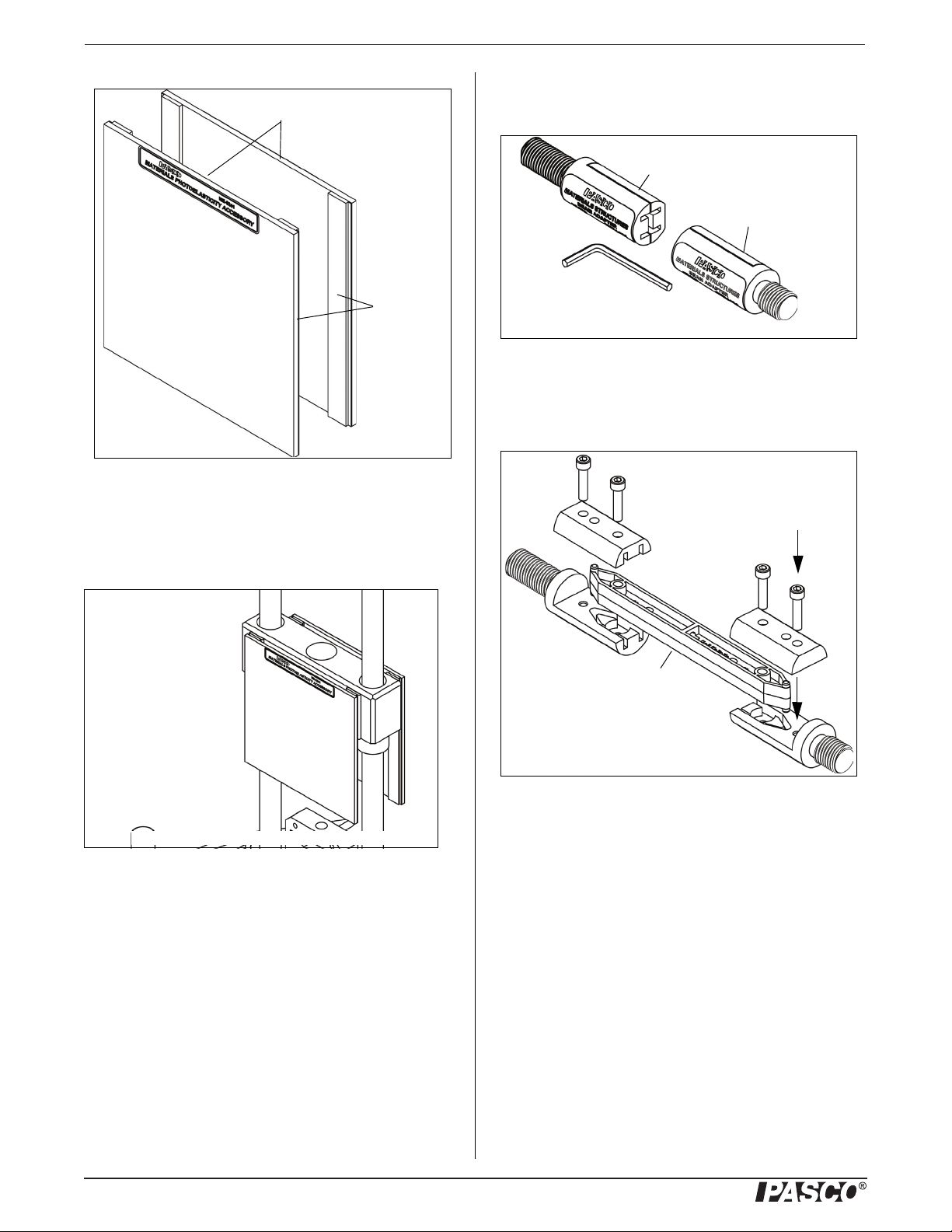

The Materials Testing Machine includes a calibration rod

and nut, a load bar round nut, and a pair of safety shields

with Velcro® hook material.

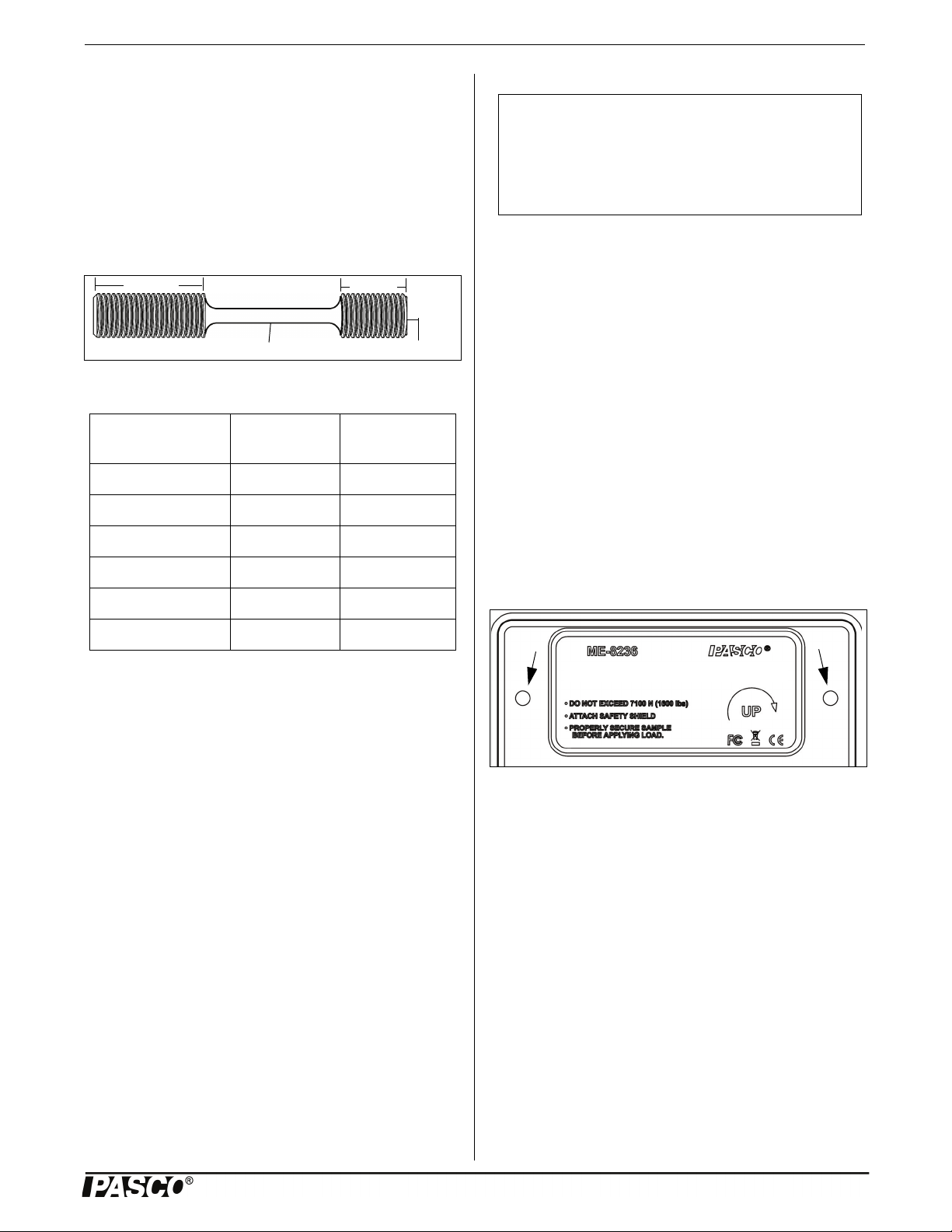

Calibration Rod and Nut, Load Bar Round Nut,

Safety Shields

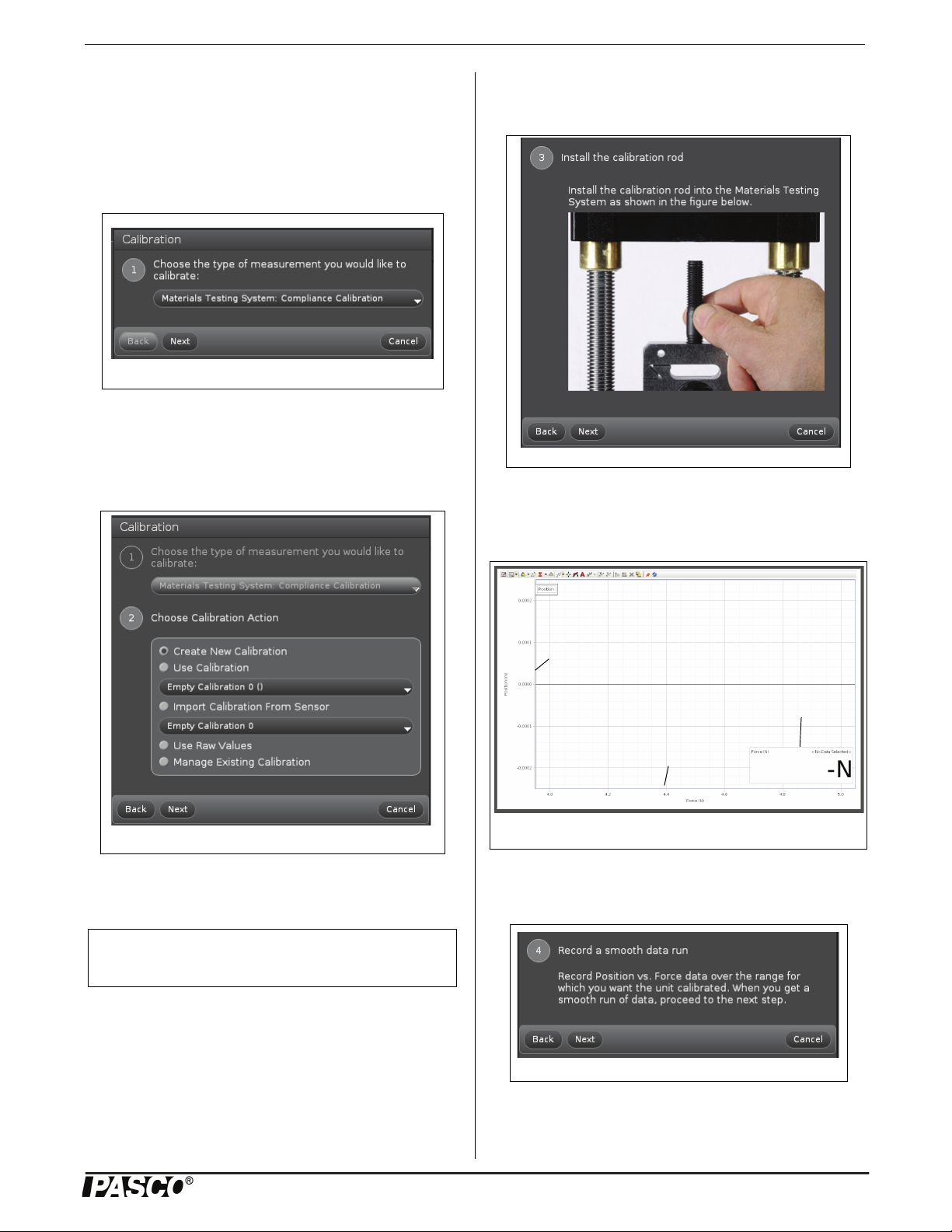

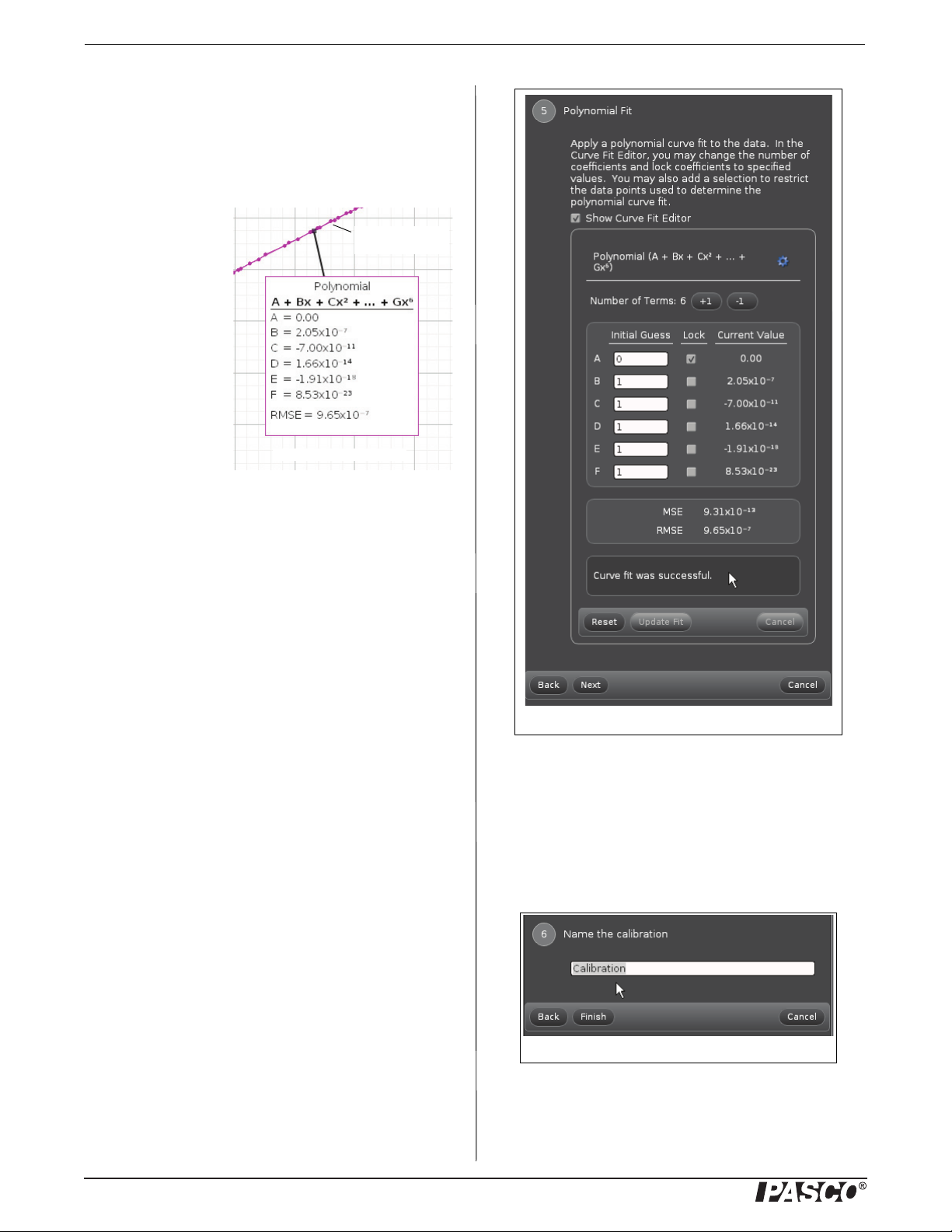

• The calibration rod and nut can be used to determine

how much the Machine itself flexes as force is applied,

either in tension or in compression.

• The load bar round nut is used to connect one end of a

tensile sample to the load bar, for example, or can be

used to attach an accessory or adapter to the load bar.

• The safety shields attach to the Velcro® loop material

on the front and back of the load bar.

Materials Testing System

The Materials Testing System (ME-8230) consists of the

Materials Testing Machine, plus a PASPORT interface called

the USB Link, PASCO Capstone Software, and sixty tensile

samples.

The USB Link connects the sensor cable of the Materials

Testing Machine to a USB port on a computer. The PASCO

Capstone software records, displays, and analyzes the data

from the Materials Testing Machine. The software is avail-

able as an automatic digital download from PASCO.

Included Items Included Items

Materials Testing Machine Calibration Rod and Nut

Load Bar Round Nut Safety Shield (2)

Required Items*

PASCO Interface (PASPORT compatible)

PASCO Capstone Data Acquisition Software

Model Materials Testing System Items

ME-8236 Materials Testing Machine

PS-2100A USB Link

UI-5401 PASCO Capstone Software

ME-8231 Tensile Sample, Aluminum (10)

ME-8232 Tensile Sample, Brass (10)

ME-8233 Tensile Sample, Annealed Steel (10)

ME-8234 Tensile Sample, Acrylic (10)

ME-8235 Tensile Sample, Polyethylene (10)

ME-8243 Tensile Sample, Steel (10)

Model Accessories

ME-8237 Materials Bending Accessory

ME-8238 Materials Coupon Adapter

ME-8239 Materials Shear Accessory

ME-8241 Materials Photoelasticity Accessory

ME-8242 Materials Structures Beam Adapter

ME-7011 Photoelastic I-Beams (24 each size)

Model Other Items

ME-8240 Materials Shear Samples (3 ea. of 3)

AP-8222* Coupons, Plastic (10 each of 4 types)

AP-8223* Coupons, Metal (10 each of 5 types)

Recommended Items

Structures Cast Beam Set (ME-7009)

Truss Set Members (ME-6993)