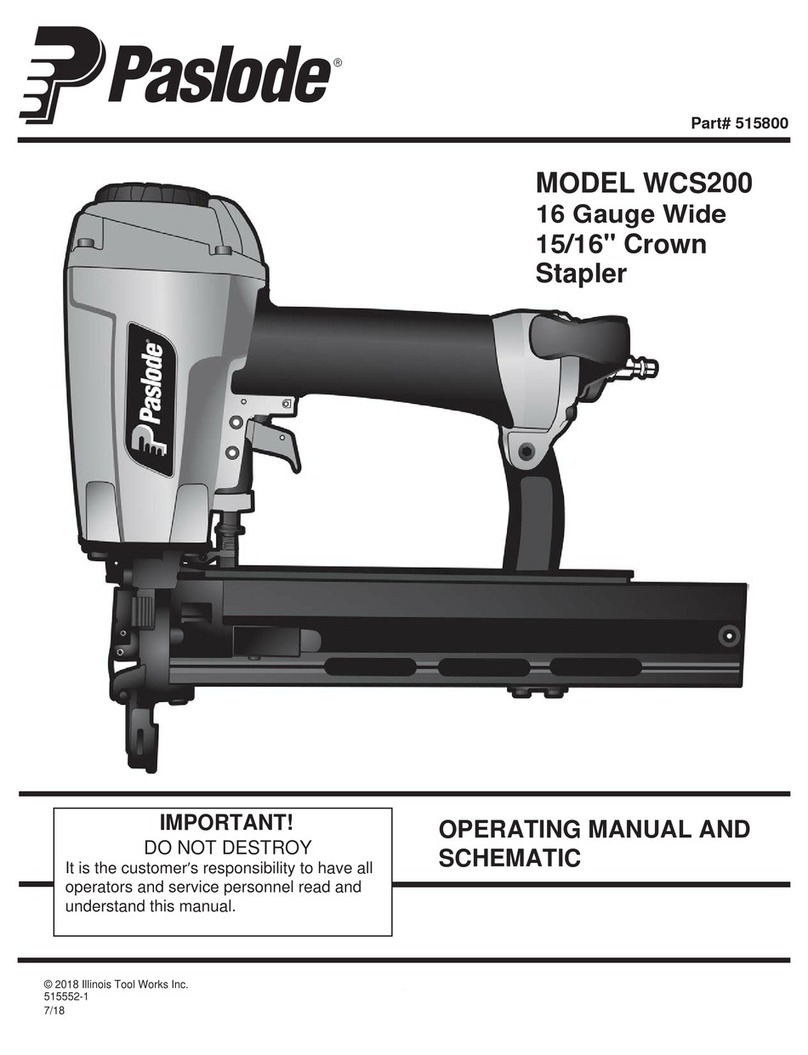

4

WARNING

Failure to follow any of the above instructions could result in severe personal

injury to tool user and bystanders or cause damage to tool and property.

SAFETY INSTRUCTIONS

SAFETY FIRST

These safety instructions provide information necessary

for safe operation of tools.

DO NOT ATTEMPT

TO OPERATE THE TOOL UNTIL YOU READ AND

UNDERSTAND ALL SAFETY PRECAUTIONS AND

MANUAL INSTRUCTIONS.

WEAR EYE AND HEARING PROTECTION

Always wear hearing and eye protection devices, that

conform to ANSI Z87.1 requirements, when operating

or working in the vicinity of a tool. As an employer you

are responsible for enforcing the use of eye protection.

Wear hard hats in environments that require their use.

THE TOOL MUST BE USED ONLY FOR THE PUR-

POSE FOR WHICH IT WAS DESIGNED

Do not throw the tool on the floor, strike the housing in

any way or use the tool as a hammer to knock

material into place.

NEVER ENGAGE IN HORSEPLAY WITH THE TOOL

The tool is not a toy so do not use it like one. Never

engage in horseplay with the tool or point it at yourself

or any other person, even if you think it is not loaded.

NEVER ASSUME THE TOOL IS EMPTY

Check the magazine for fasteners that may be left in the

tool. Even if you think the tool is empty or disconnected,

never point it at anyone or yourself. Unseen fasteners

could fire from the tool.

NEVER CLAMP THE TRIGGER IN A LOCKED OR

OPERATING POSITION

The trigger of the tool must never be tampered with,

disabled or clamped in a locked or operating position

since this will cause the tool to drive a fastener any time

the work contacting element depressed.

DO NOT LOAD FASTENERS WITH THE AIR LINE

CONNECTED, OR WITH THE TOOL TRIGGER OR

WORK CONTACTING ELEMENT DEPRESSED

When loading fasteners into the tool be sure you

disconnect the air line and that you do not depress

the trigger or work contacting element.

OPERATE THE TOOL ONLY ON A WORKPIECE

The tool should be operated only when it is in contact

with the workpiece. Even then you should be careful

when fastening thin material or working near the edges

and corners of the workpiece since the fasteners may

drive through or away from the workpiece.

DO NOT DISABLE OR REMOVE THE WORK

CONTACTING ELEMENT

This tool is equipped with a safety mechanism, called a

work contacting element, to help prevent

accidental firing. Never tamper with, disable or remove

the work contacting element. Do not use the tool unless

the work contacting element is working properly. The

tool could fire unexpectedly.

DISCONNECT THE TOOL WHEN NOT IN USE

Always disconnect the tool from the air line when it

is not in use, when you leave the work area or when

moving the tool to a new location. The tool must

never be left unattended because people who are

not familiar with the tool might handle it and injure

themselves or others.

CARRY THE TOOL ONLY BY THE HANDLE

Always carry the tool by the handle only. Never carry

the tool by the air hose or with the trigger depressed

since you could drive a fastener unintentionally and

injure yourself or someone else.

DO NOT WEAKEN THE TOOL HOUSING

The tool housing is a pressure vessel and should never

be weakened by having your company’s name, area of

work or anything else stamped or engraved into its

surface.

DISCONNECT THE TOOL WHEN PERFORMING

REPAIRS AND CLEARING JAMS

Never attempt to clear a jam or repair a tool unless you

have disconnected the tool from the air line and

removed all remaining fasteners from the tool.

ALWAYS USE THE PROPER FITTING FOR THE

TOOL

Only MALE pneumatic type air connectors should be

fitted to the tool, so that high pressure air in the tool is

vented to atmosphere as soon as the air line is

disconnected.

NEVER install FEMALE quick disconnect couplings on

the tool. Female couplings will trap high pressure air in

the tool when the air line is disconnected, leaving the

tool charged and able to drive at least one fastener.

DO NOT EXCEED THE MAXIMUM RECOMMENDED

AIR PRESSURE

.erusserpriadednemmocerehttaylnolootehtetarepO

Do not exceed the maximum air pressure marked on

the tool. Be sure the air pressure gauge is

operating properly and check it at least twice a day.

Never use any bottled air or gases such as oxygen to

operate the tool since they could cause the tool to

explode.

INSPECT TOOL FOR PROPER OPERATION

.deriuqersaetacirbuldnayliadtsaeltalootehtnaelC

Never operate a dirty or malfunctioning tool.

USE ONLY

Paslode

RECOMMENDED PARTS AND

FASTENERS

Use only parts and fasteners specifically designed and

recommended by

Paslode

for use in the tool and

for work to be done. Using unauthorized parts and

fasteners or modifying the tool in any way creates

dangerous situations. Replace all missing warning

labels---refer to tool schematic for correct placement

and part number.

®

®

Paslode

®