3

Trademarks

Pax®, MZ-One®and Clust-Air®are protected trademarks of Pax GmbH. Any other designation used

in this documentation may be a trademark whose use by any third party and for the purposes of such

third party may violate the rights of its holders.

Disclaimer of liability

This documentation is an English translation of the original German installation and operating

instructions. After completion of the installation, it should be passed onto the user (tenant, owner,

building management, etc.).

The contents of this documentation have been checked for compliance with the hardware and

software described. However, discrepancies cannot be ruled out, so complete compliance cannot be

guaranteed. This documentation will be updated on a regular basis. Any correction required or any

useful additions will be included in subsequent editions as a general rule.

Version 1.5.00

Table of contents

1 User and safety instructions .................................................................................................. 4

1.1 Safety instructions.......................................................................................................... 4

1.2 Intended use .................................................................................................................. 5

1.3 Incorrect use .................................................................................................................. 5

1.4 Qualied personnel ........................................................................................................ 5

1.5 General symbols ............................................................................................................ 5

2 System overview ..................................................................................................................... 6

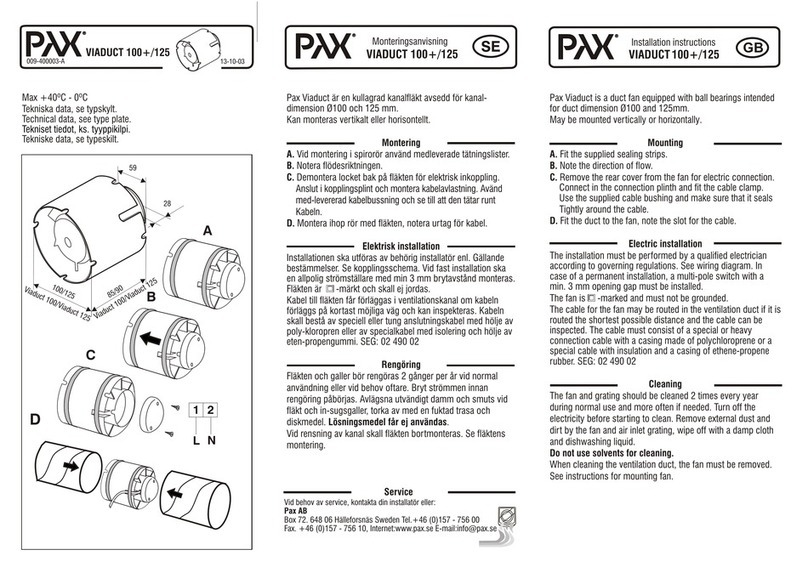

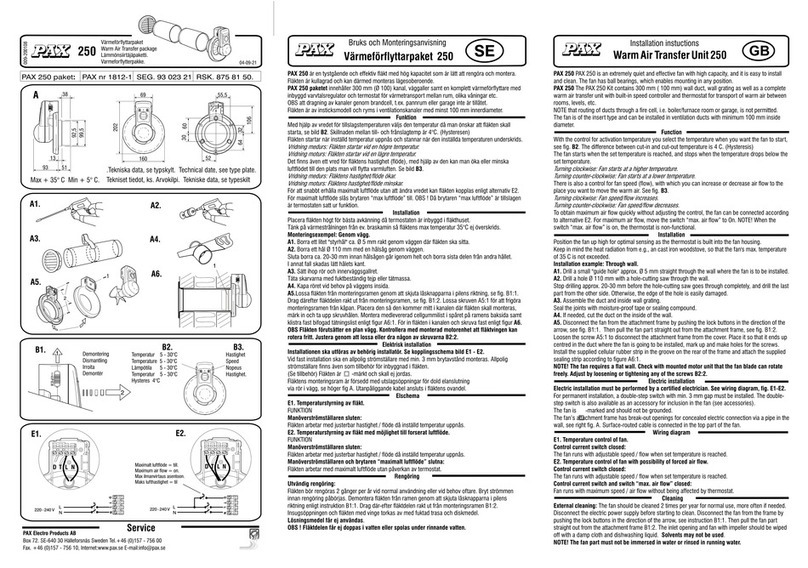

2.1 Layout ............................................................................................................................ 7

2.2 Function ....................................................................................................................... 10

2.3 Control elements ...........................................................................................................11

3 Preparations prior to installation ......................................................................................... 14

3.1 Dimensions .................................................................................................................. 14

3.2 Dimensioned drawings................................................................................................. 15

4 Electrical connections .......................................................................................................... 19

5 Assembly and installation .................................................................................................... 20

5.1 Preparation sets ........................................................................................................... 20

5.2 Completion set ............................................................................................................. 21

5.3 Information on RAL-compliant installation.................................................................... 21

5.4 Creating the wall opening/plaster groove..................................................................... 22

5.5 Laying the controller cable ........................................................................................... 23

5.6 Fitting the wall sleeve................................................................................................... 24

5.7 Fitting the weather protection hood.............................................................................. 28

5.8 Installing the corner at tube........................................................................................ 34

5.9 Installing the embrasure lattice .................................................................................... 37

5.10 Installing the thermal accumulator ............................................................................... 39

5.11 Starting the ventilation system ..................................................................................... 41

5.12 Fitting an inner cover.................................................................................................... 42

6 Operation................................................................................................................................ 45

6.1 Opening/closing the inner cover................................................................................... 45

6.2 Replacing the dust lter................................................................................................ 47

6.3 Installing/removing the thermal accumulator................................................................ 50

6.4 Cleaning the thermal accumulator ............................................................................... 54

7 Specication .......................................................................................................................... 55

8 Standard delivery, accessories and spare parts ................................................................ 58

9 Servicing and maintenance .................................................................................................. 63

10 Troubleshooting and disposal ............................................................................................. 65

11 Warranty and service ............................................................................................................ 67

Company details.................................................................................................................... 71

TABLE OF CONTENTS