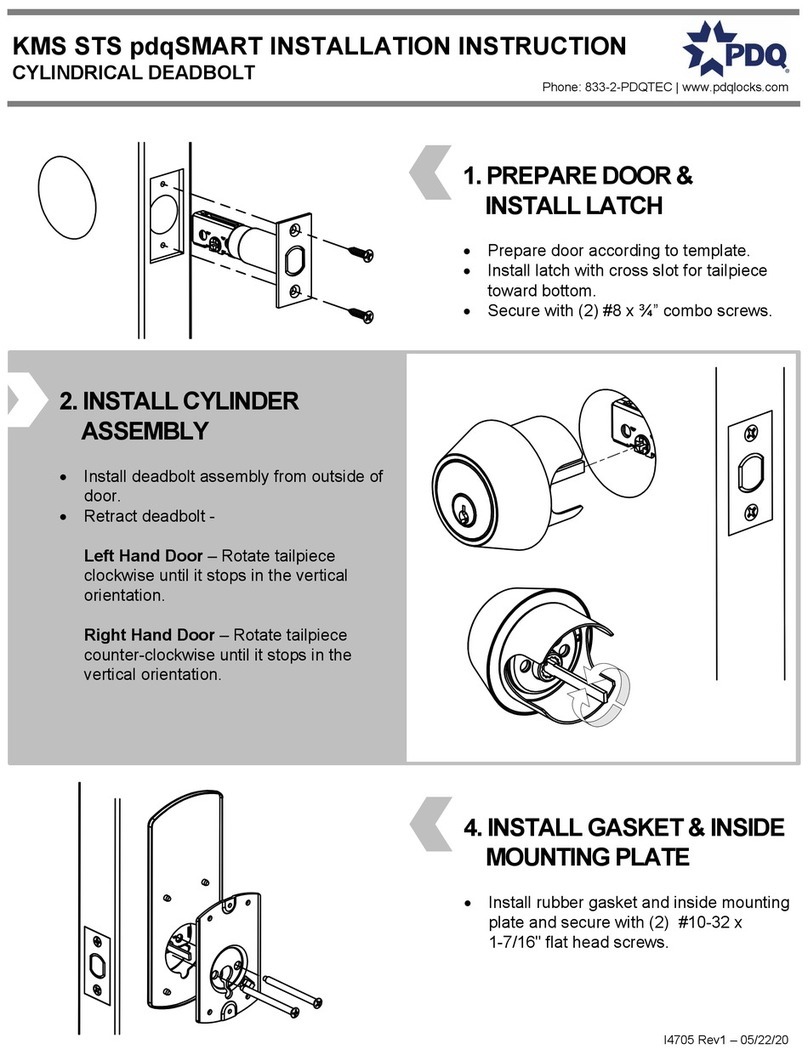

1. DOOR PREPARATION

Prepare the door for the mortise lock.

Generic template in box, function specific templates

located at www.pdqlocks.com

Install the mortise case and secure using two (2) #12-24

combo screws supplied in the hardware kit.

2. JAMB PREPARATION

Prepare the jamb for the mortise lock strike.

Install Dead Latch Plate behind strike with slider toward bottom for

dead latch.

Install the strike and secure with two (2) #12-24 combo screws

supplied in the strike screw pack.

Dead Latch

Slider

MR – MORTISE LOCK F-TYPE SECTIONAL TRIM

INSTALLATION INSTRUCTION Phone: 833-2-PDQTEC | www.pdqlocks.com

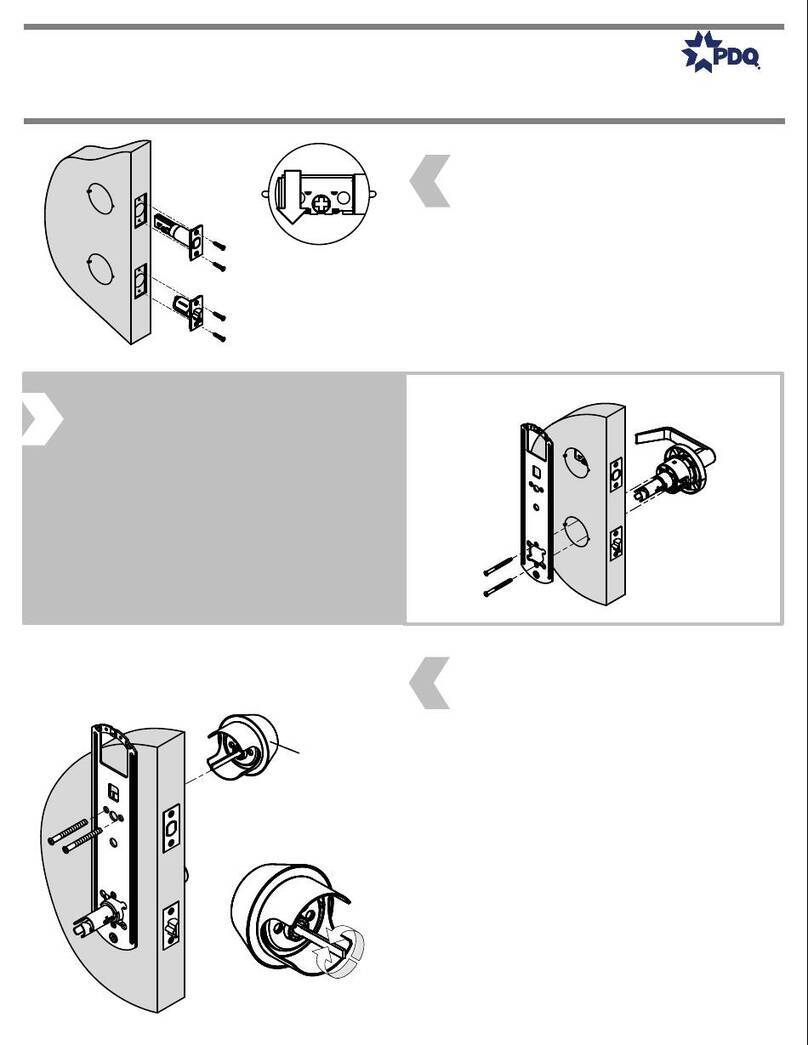

3. SECTIONAL TRIM HANDING

NOTE: The trim is handed as labeled from the factory.

OUTSIDE TRIM

Pull out on the spindle out of the lever and hold.

Note: The spindle is captured and will not be completely

removed from the trim assembly.

While holding the spindle and rose plate rotate the lever to the new operating

position.

Raise the lever to 60° above horizontal and hold.

Release the spindle and apply light pressure on the end of the spindle.

Lower the lever to the horizontal operating position.

- As the lever is lowered the spindle will re-engage with the lever

- Verify this by rotating the lever down from horizontal.

- The springs in the assembly will compress as the lever is rotated.

INSIDE TRIM

Remove the lever and rose scalp.

Orient the rose plate as it will be installed on the door and hold.

Note: The thru-bolt holes will be at 12 o'clock and 6 o'clock

- The rose plate does not have a top or a bottom.

Rotate the square spindle toward the hinge side of the door.

- RH and RHR doors, rotate the spindle CCW, counter clockwise.

- LH and LHR doors, rotate the spindle CW, clockwise.

6. INSTALL ARMOR PLATE

Install the armor plate with two (2) stainless steel #8-32 x 1/4"

flat head machine screws.

W53053 Rev0 – 11/20/19

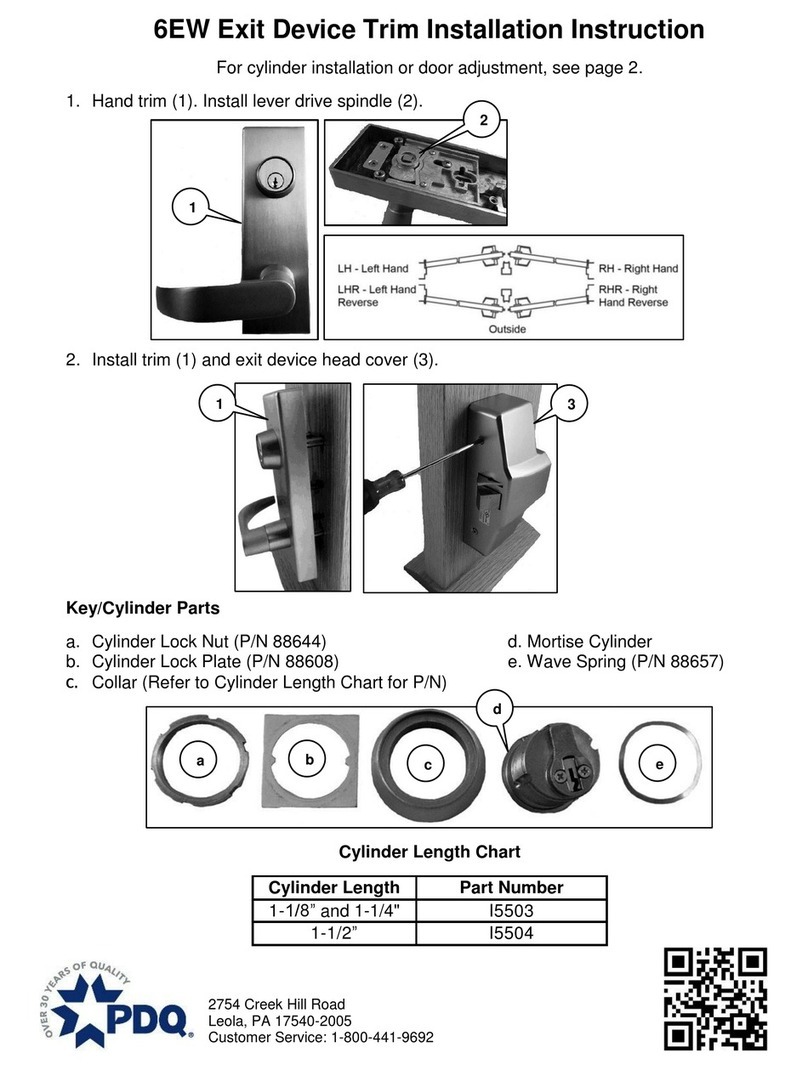

5. INSTALL CYLINDER / THUMB TURN

CYLINDER

Install cylinder and adjust, making it flush or slightly recessed

into the escutcheon

For I/C housings, install the slotted set screw through the I/C

bore to secure the housing.

Secure the cylinder by tightening the cylinder set screw

through the front of the case with the supplied 2.5mm hex key.

Does not apply to I/C when using slotted set screw.

THUMB TURN

Insert the thumb turn.

Secure the thumb turn with two (2) #6 truss head screws

supplied in the screw pack.

Cylinder Set

Screw –

Tighten

side(s) with

cylinder

Lever

Spindle

OUTSIDE TRIM

Rose

Plate

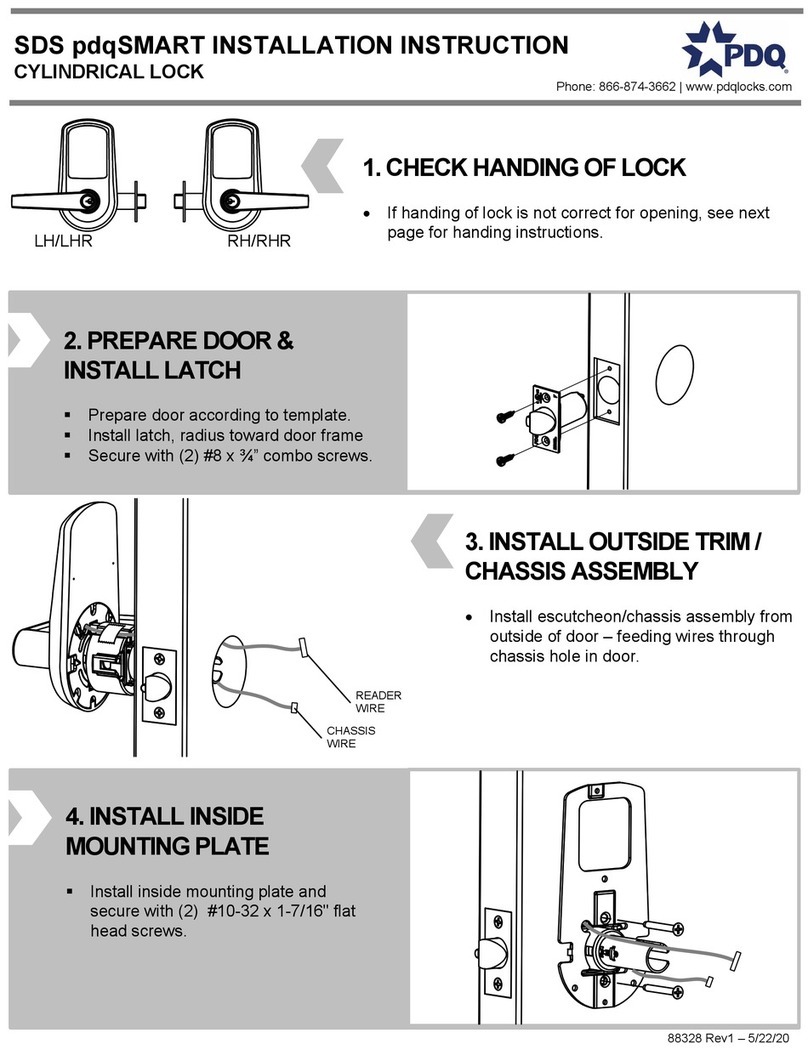

4. INSTALL SECTIONAL TRIM / ROSE

OUTSIDE TRIM

Install rose to door while aligning the spindle with the lock hub.

Confirm the spindle engagement in the lock by rotating the

lever down and verifying that the latch retracts.

INSIDE TRIM

Install the inside rose assembly to the inside of the door. Align

the spindle with the lever.

Secure inside rose assembly with #10-24x1-1/2" flat head

machine screws, supplied in the hardware kit, Confirm the

spindle engagement.

Install the rose scalp by aligning the dimples with the slots in

the rose plate. Secure by rotating clockwise until tight.

Set Screw

Rose

Plate

Rose

Spindle

INSIDE TRIM

Spindle