5 of 10 ISSUED: 05-02-06 SHEET #:202-9089-6 (2017-01-13)

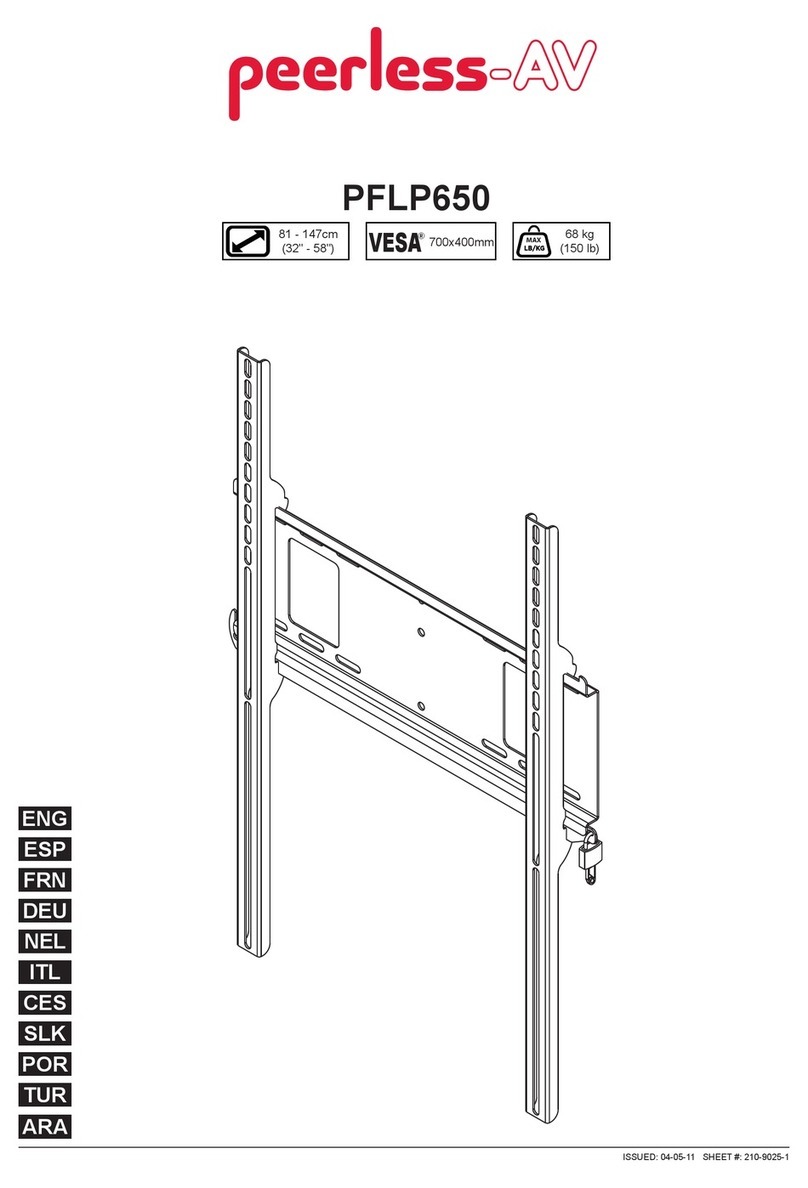

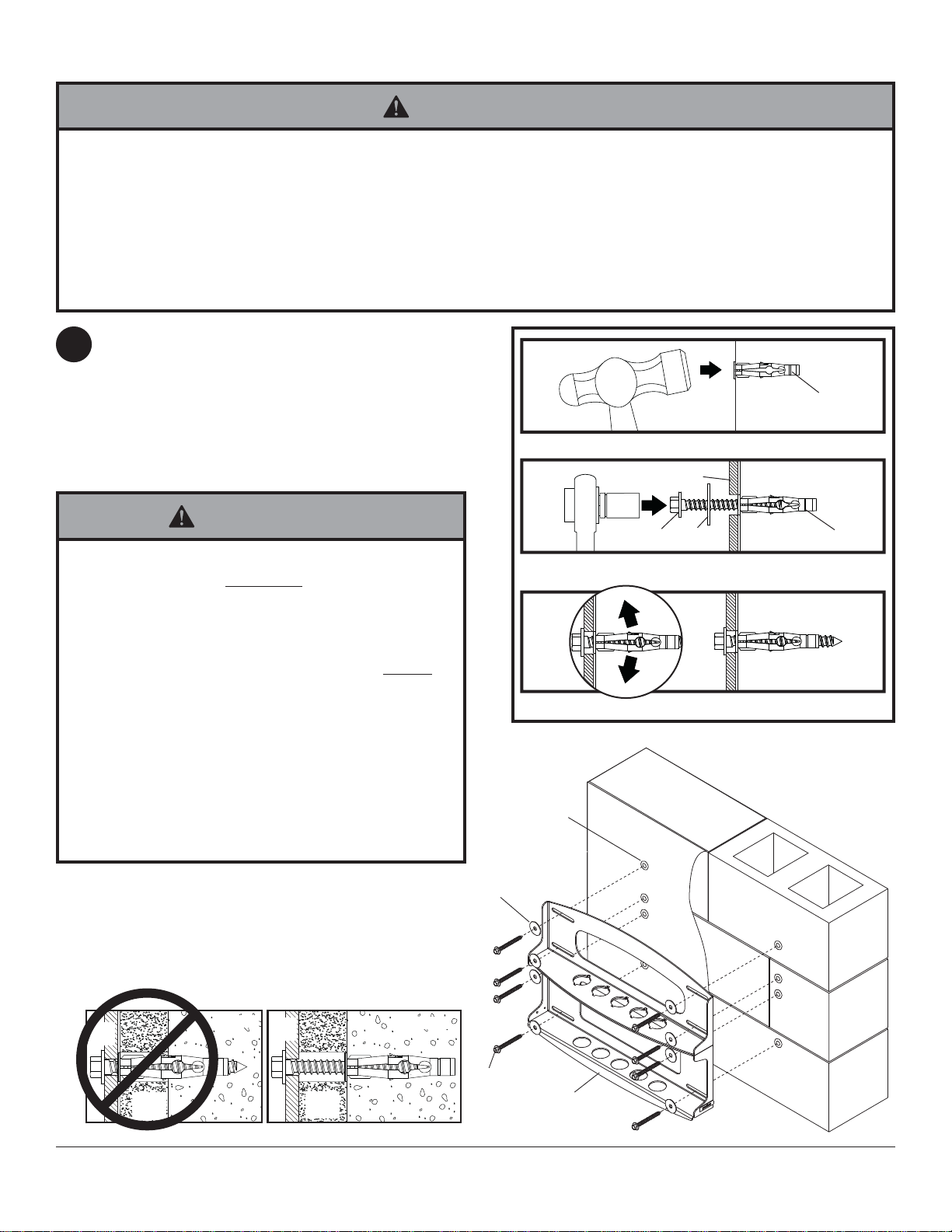

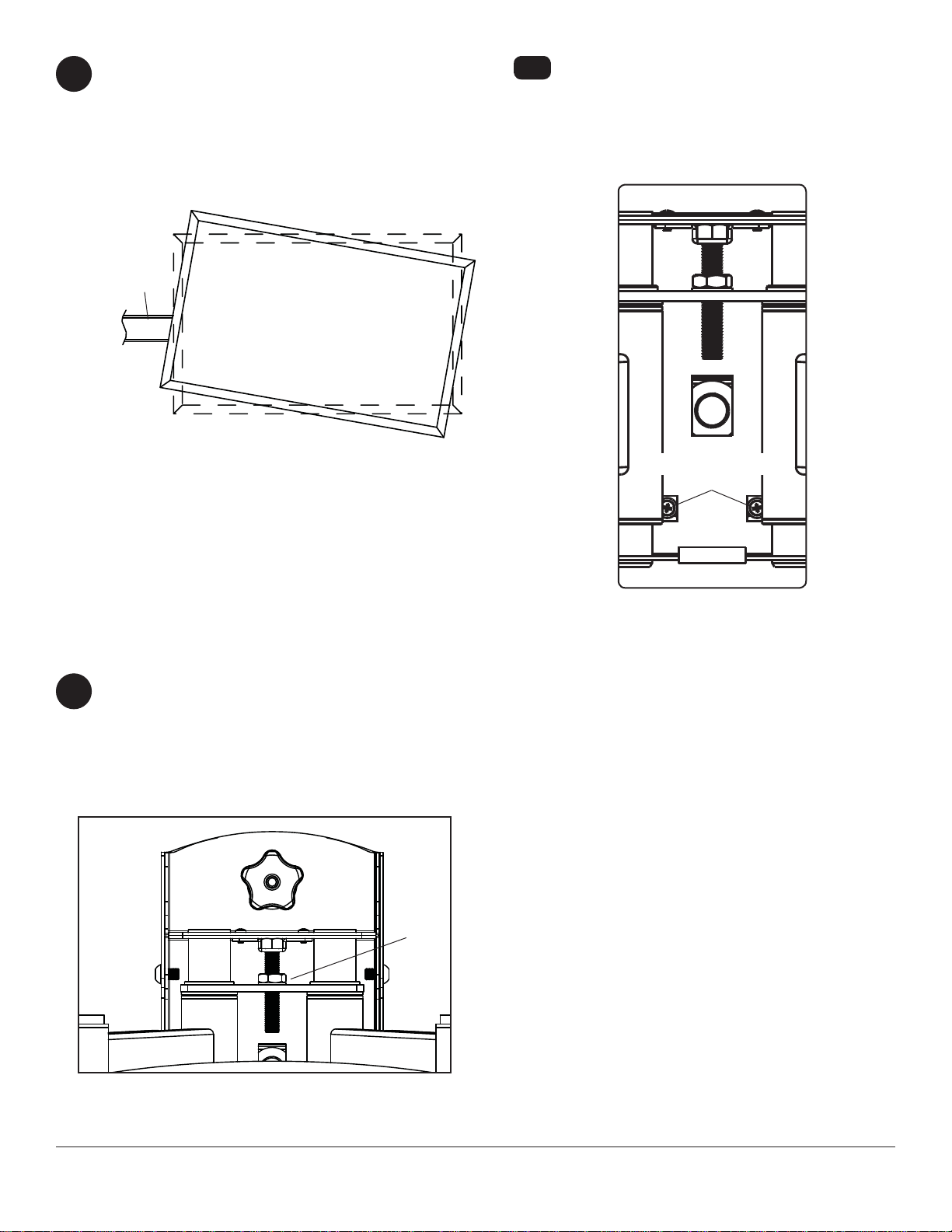

Use wall plate (A), making sure that it is level, as

a template to mark holes. The top mounting slots

should be located .43" below the desired screen

center. Use the masonry bit to drill 3/8" (10mm)

dia. holes to a minimum depth of 3" (76 mm). Insert

anchors (V) in holes flush with wall as shown (right).

Place wall plate (A) over anchors (V) and secure

with 5/16 x 3" wood screws (O) and washers (P).

1

Installation to Solid Concrete or Cinder Block Wall

A

O

P

V

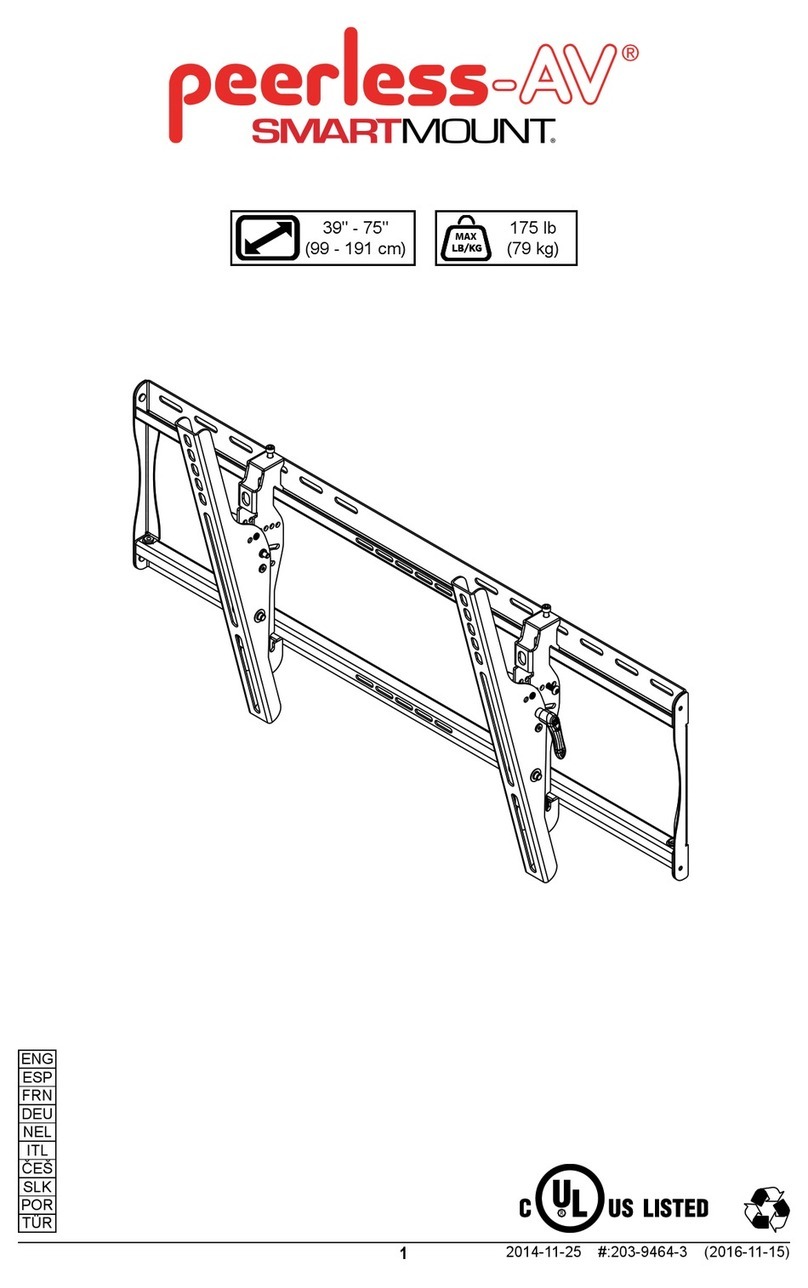

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a

solid part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90

specifications. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

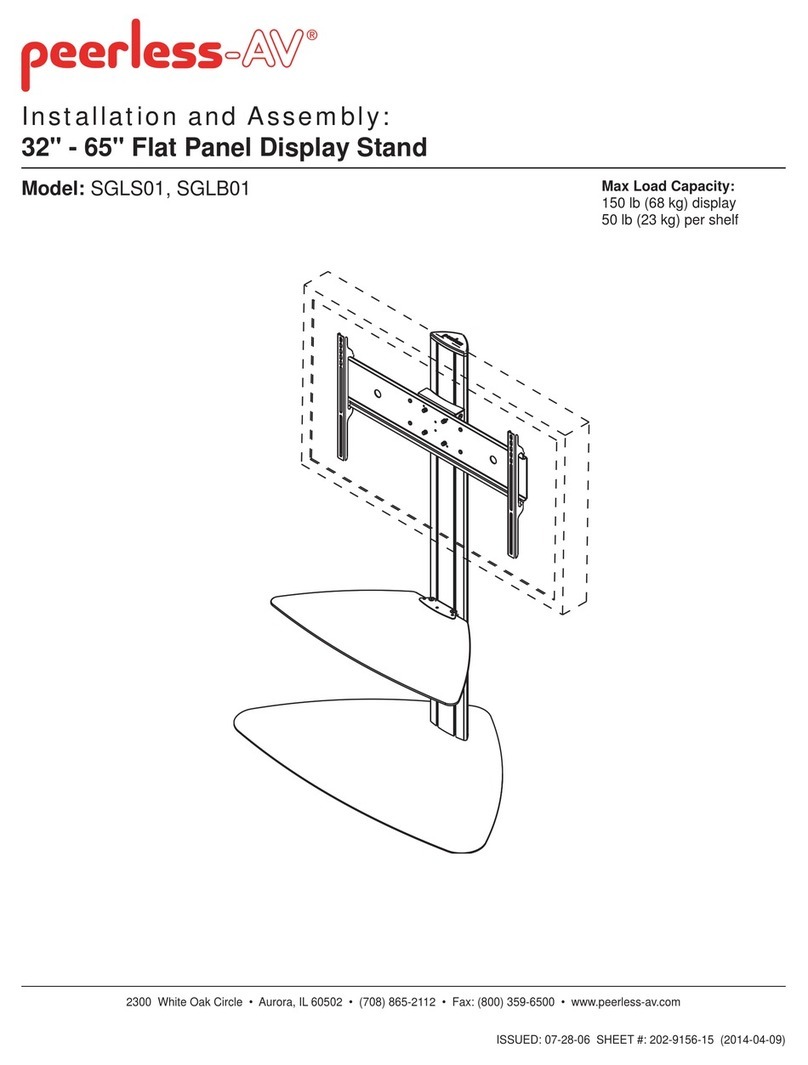

WARNING

• Tighten wood screws so that wall plate is firmly

attached, but do not overtighten. Overtightening

can damage screws, greatly reducing their holding

power.

• Never tighten in excess of 80 in • lb (9 N.M.).

• Always attach concrete expansion anchors directly

to load-bearing concrete.

• Never attach concrete expansion anchors to con-

crete covered with plaster, drywall, or other finishing

material. If mounting to concrete surfaces covered

with a finishing surface is unavoidable (not evaluated

by UL), the finishing surface must be counterbored

as shown below. If plaster/drywall is thicker than

5/8", custom fasteners must be supplied by installer

(not evaluated by UL).

WARNING

1

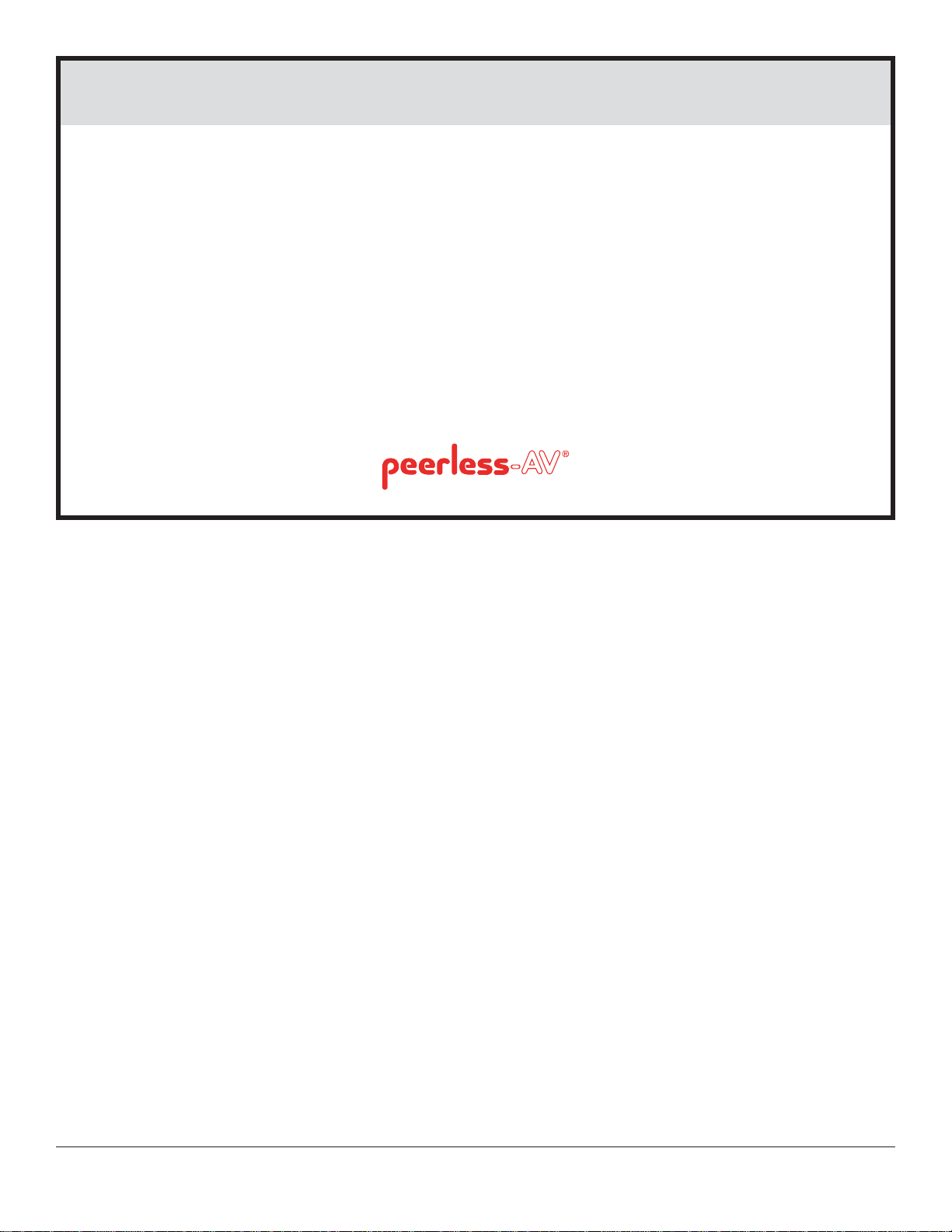

3

2

V

Drill holes and insert anchors (V).

Place plate (A) over anchors (V) and secure with screws (Q).

Tighten all fasteners.

A

V

O

concrete

surface

CUTAWAY VIEW

INCORRECT CORRECT

wall

plate wall

plate

plaster/

drywall plaster/

drywall

concrete concrete

P