Det är VIKTIGT att försäkra sig om att tappen

möter kolven rakt. Lyft och sänk locket och se

till att du kan höra mikrobrytaren fungera. Det

kan vara nödvändigt att böja tappen något för att

säkerställa korrekt funktion.

Remskivorna kan nu monteras. Observera att de

inte är utbytbara. Motoraxelremskivan är placerad

med en nyckel och en fjädrande tryckskruv, och

ett kilspår är därför förberett i borrningen, medan

växellådans remskiva inte har något kilspår och är

belägen med en fjädrande tryckskruv på en platta

fräst i axeln.

VIKTIGT. Vid montering, se till att den motor eller

drivhjul med minsta diameter driver den växellåda

eller bladskiva med störst diameter, dvs de är

monterade omvänt mot varandra. Det är normalt att

montera drivhjulet med minsta diameter inåt och

växellådans remskiva med minsta diameter utåt

(som illustreras i deldiagrammet, Fig 3, sida 6).

Placera växellådans remskiva på sin axel, se till att

tryckskruven hamnar i linje med plattan på axeln.

Dra åt tryckskruven helt. Montera motorskivan på

axeln så att den hamnar i linje med växellådans

remskiva. Detta kan göras med en rak kant över

remskivans topp för att säkerställa att spåren är i

linje. Vid korrekt inriktning, dra åt den medföljande

tryckskruven.

Observera att motorn svänger runt dess fästen.

För att passa in drivremmen lyfter du motorn

och låter remmen glida över remskivorna.

Remspänning utförs med hjälp av en bult genom

motorns monteringsplatta. Skruva fast bulten "in"

tills remmen kan tryckas ned ca 1,3cm i mitten.

Lås justerskruven med hjälp av den medföljande

låsmuttern.

VIKTIG. Överdra inte justeringsbulten eftersom det

kommer att förvrida motorns monteringsplatta.

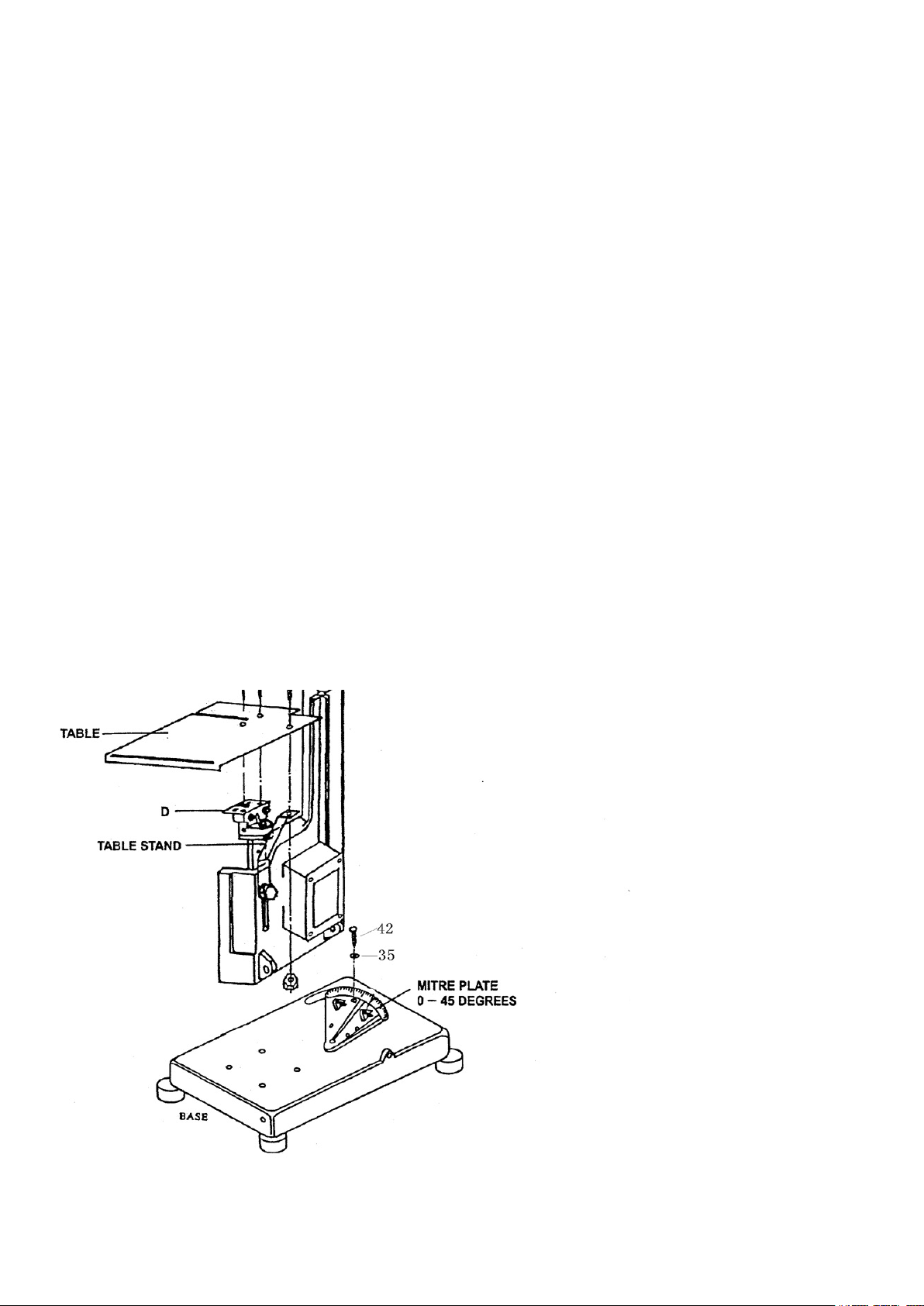

Arbetsstoppmontering:

Ett arbetsstopp (Fig. 1, punkt 7) medföljer, vilket

används för att låta arbetsstycken av samma

längd skäras utan att man behöver mäta varje

stycke individuellt. Den består av två delar,

arbetsstoppet och monteringsstången. Skjut

stången i hålet i städets kant och säkra med

medföljande tryckskruv. Montera arbetsstoppet på

stången, med det platta riktat mot sågklingan och

säkra tillfälligt med den medföljande tryckskruven,

se till att den inte trycks in för långt, eftersom det

kan störa sågklingan när den sänks.

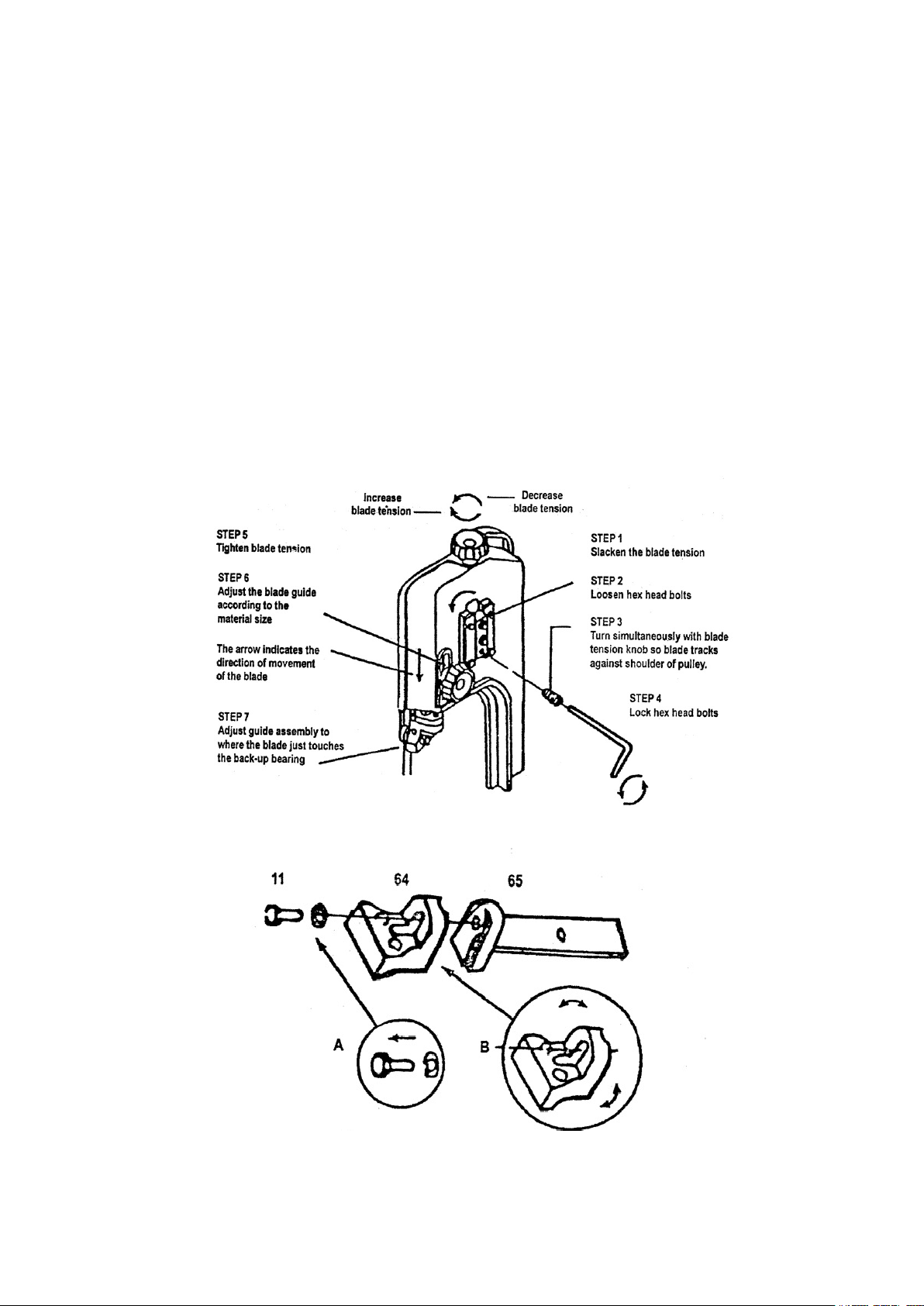

Justering av sågbladsstyrningen:

Metallbandsågen är utrustad med två justerbara

bladstyrningsaggregat (gur 1, punkt 8). Med den

här funktionen kan du justera bladstyrningarnas

position för olika bredder av arbetsstycken.

Bör justeras för att förbereda för det stycke som

ska skäras. Detta görs enligt följande:

1. Placera arbetsstycket i städet på bandsågen

och kläm fast. ·

2. Justera fästbladets styrenhet till önskat läge

genom att lossa handskruvar och positionera

styrningarna efter behov.

3. Dra åt handskruvarna.

Justering av sågbladsstyrningens lager:

Detta är den viktigaste justeringen på din såg. Det

är omöjligt att få tillfredsställande prestanda från

din såg om bladstyrningarna inte är rätt inställda.

Bladstyrningens lager för din metallbandsåg har

justerats och testats med era provskär innan

den lämnar fabriken för att säkerställa korrekt

inställning. Behovet av justering bör sällan ske

om sågen används korrekt. Om guiderna ändå går

ur justering är det extremt viktigt att omedelbart

justera. Om korrekt justering inte upprätthålls, skär

inte bladet rakt och om situationen inte korrigeras

kommer det att orsaka skador på bladet.

Eftersom styrjustering är en kritisk faktor vid

prestanda för sågen är det alltid bäst att prova ett

nytt blad för att se om det här kommer att korri-

gera dålig skärning innan du börjar justera lagren.

Om ett blad blir matt på ena sidan tidigare än det

andra, börjar det till exempel skära krokigt. Ett

enkelt klingbyte bör korrigera detta problem - ett

svårare behov av styrjustering kommer inte att

göra det.

Om ett nytt blad inte löser problemet, kontrollera

bladstyrningarna för korrekt avstånd. Det ska

nnas 0,0025cm frigång mellan 0,06cm tjockt

blad och styrlager. För att få denna frigång justera

enligt följande (se Fig 4, steg 7):