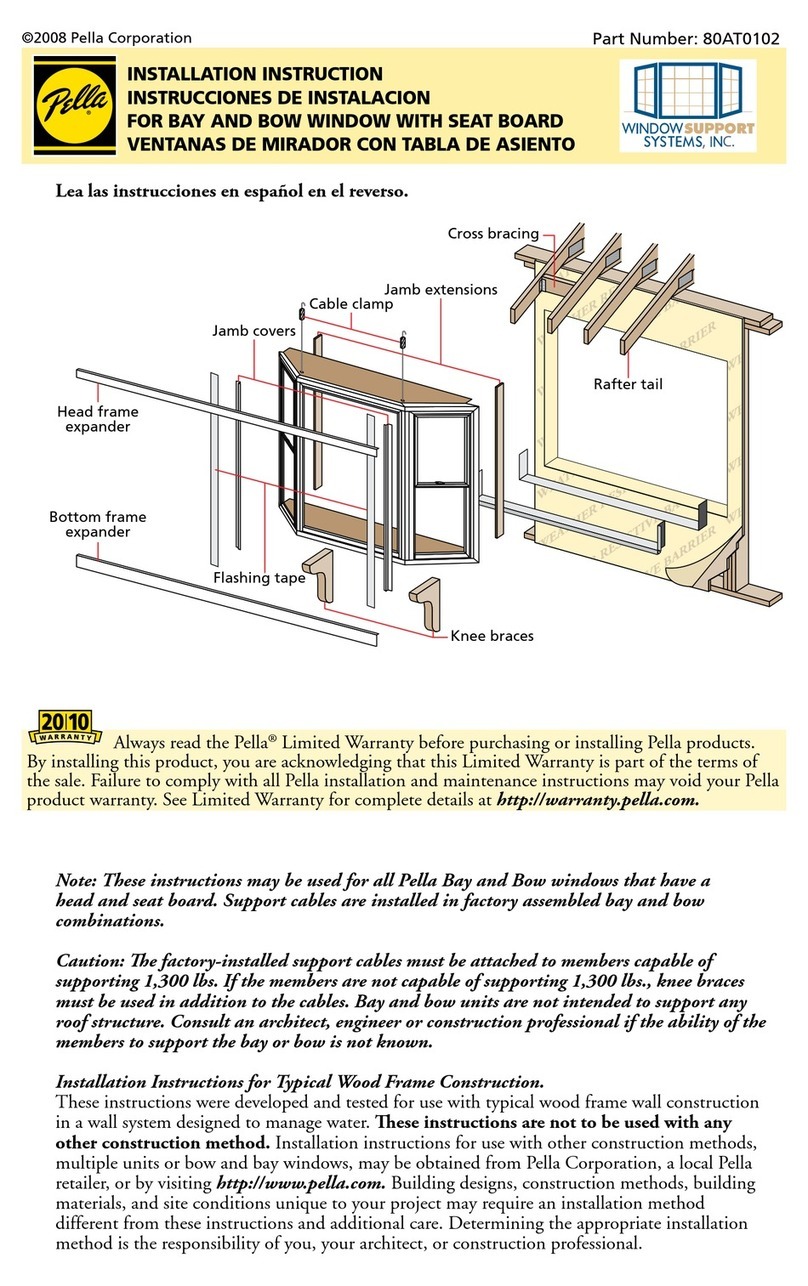

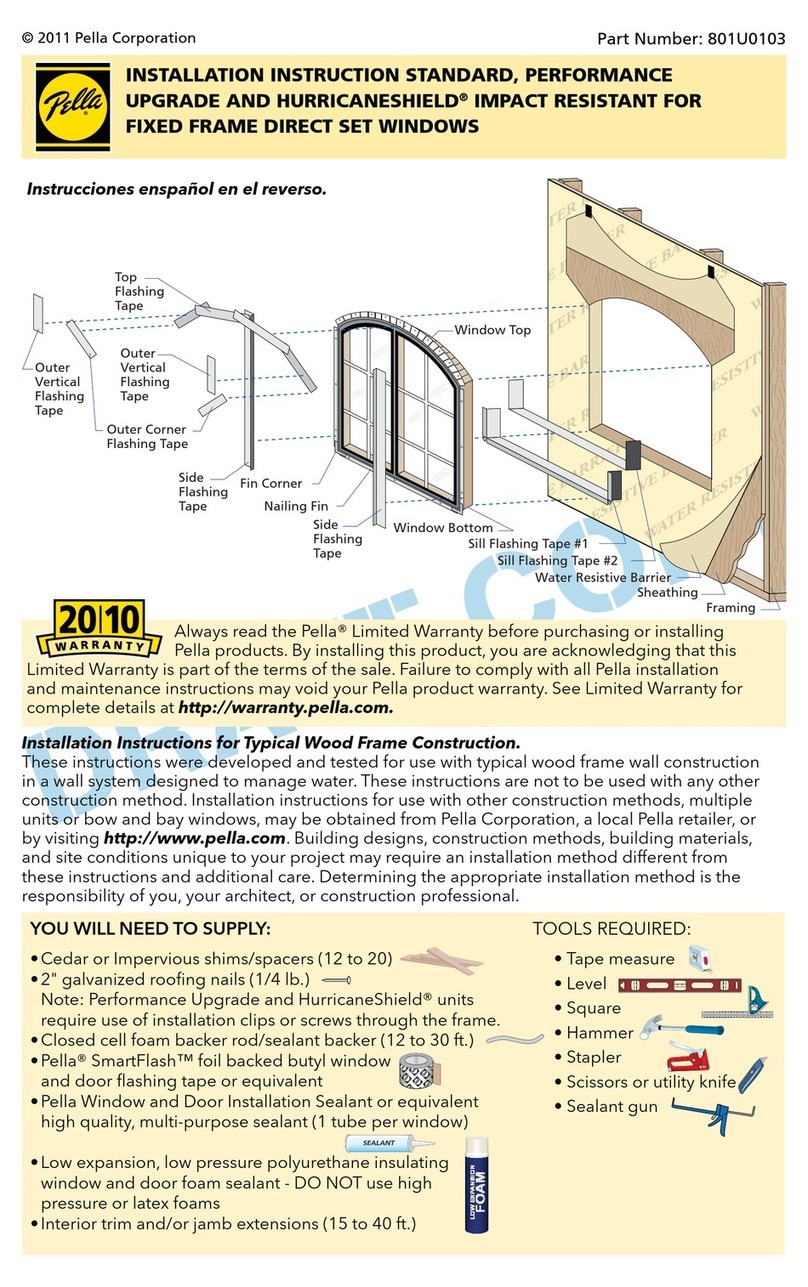

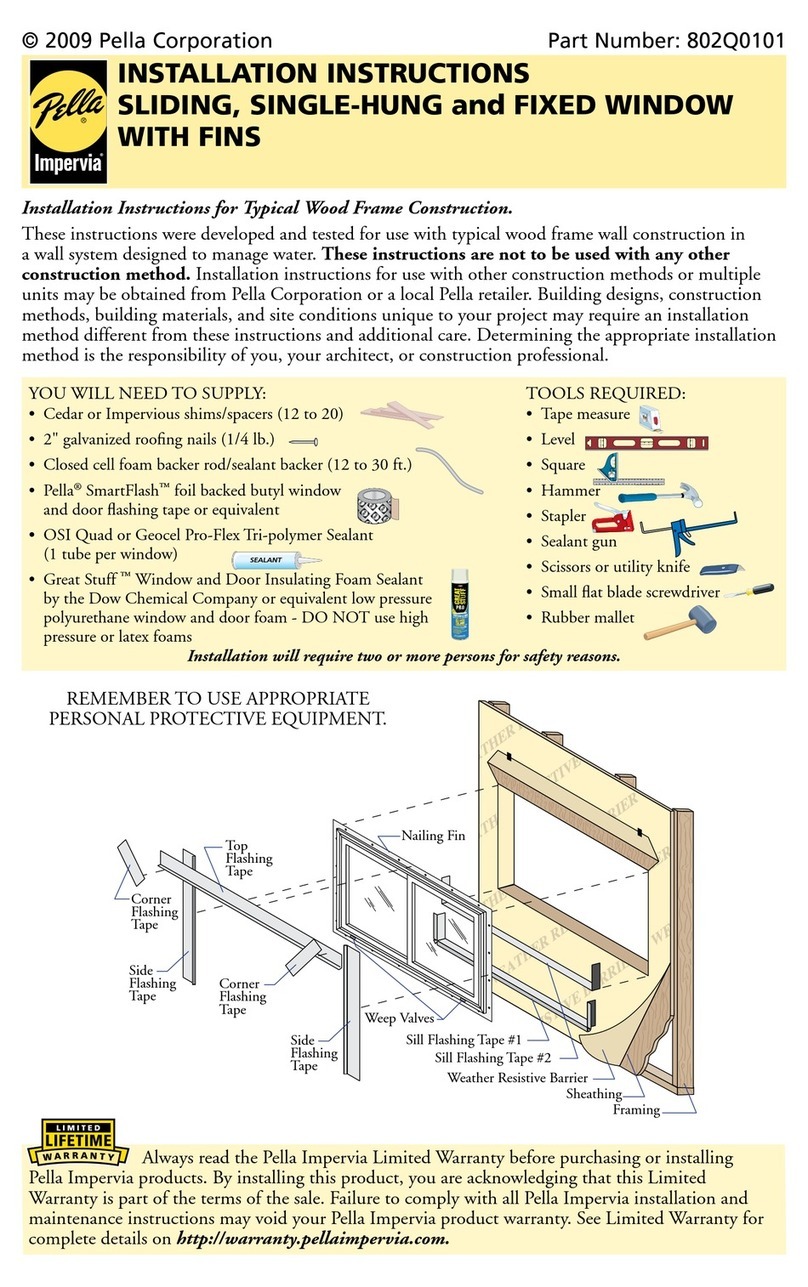

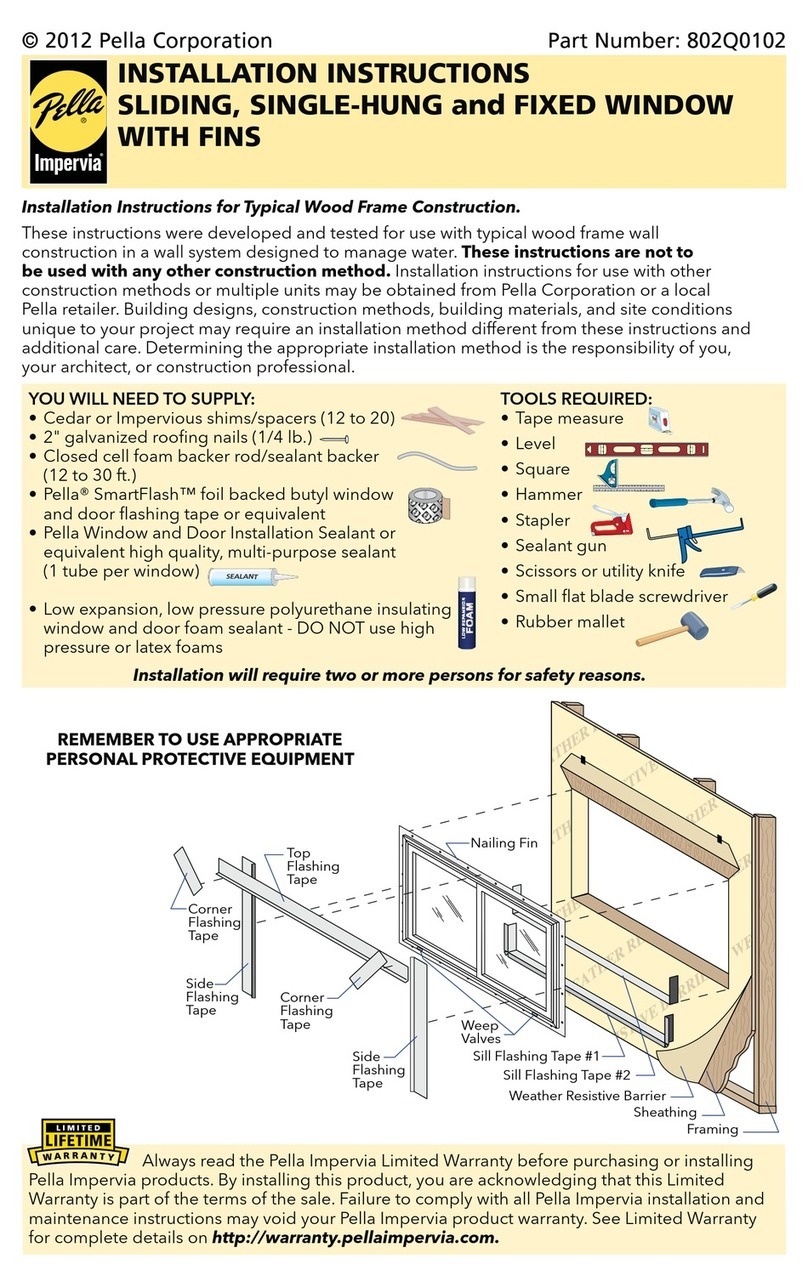

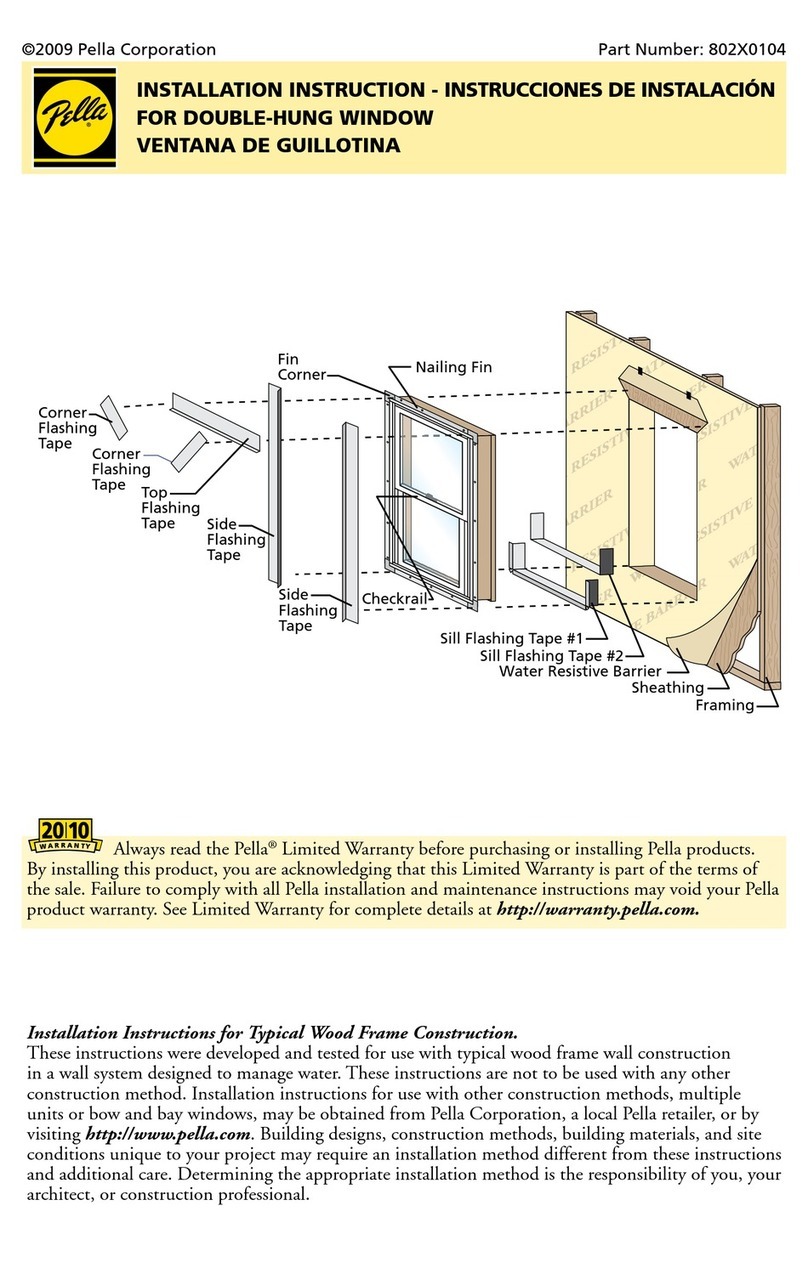

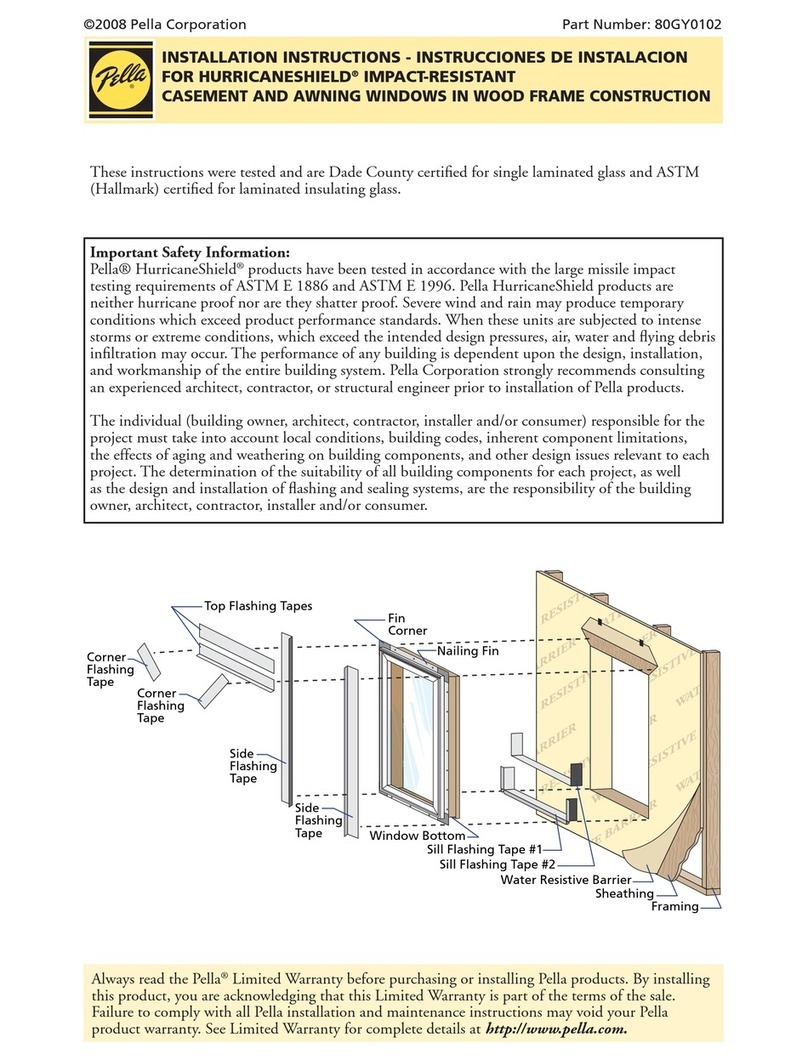

Installation Instructions for Typical Wood Frame Construction.

These instructions were developed and tested for use with typical wood frame wall construction in

a wall system designed to manage water. These instructions are not to be used with any other

construction method. Installation instructions for use with other construction methods may be

obtained from Pella®Corporation or a local Pella retailer. Building designs, construction methods,

building materials, and site conditions unique to your project may require an installation method

different from these instructions and additional care. Determining the appropriate installation method

is the responsibility of you, your architect, or construction professional.

Handling and Storage:

Provide full support under the framework while storing, moving and installing this product. DO

NOT lift the product by the head member only. Remove the plastic shipping material prior to storing

or installing the product. DO NOT store in direct sunlight. Allow sufficient spacing between products

for ventilation.

REMEMBER TO USE APPROPRIATE

PERSONAL PROTECTIVE EQUIPMENT.

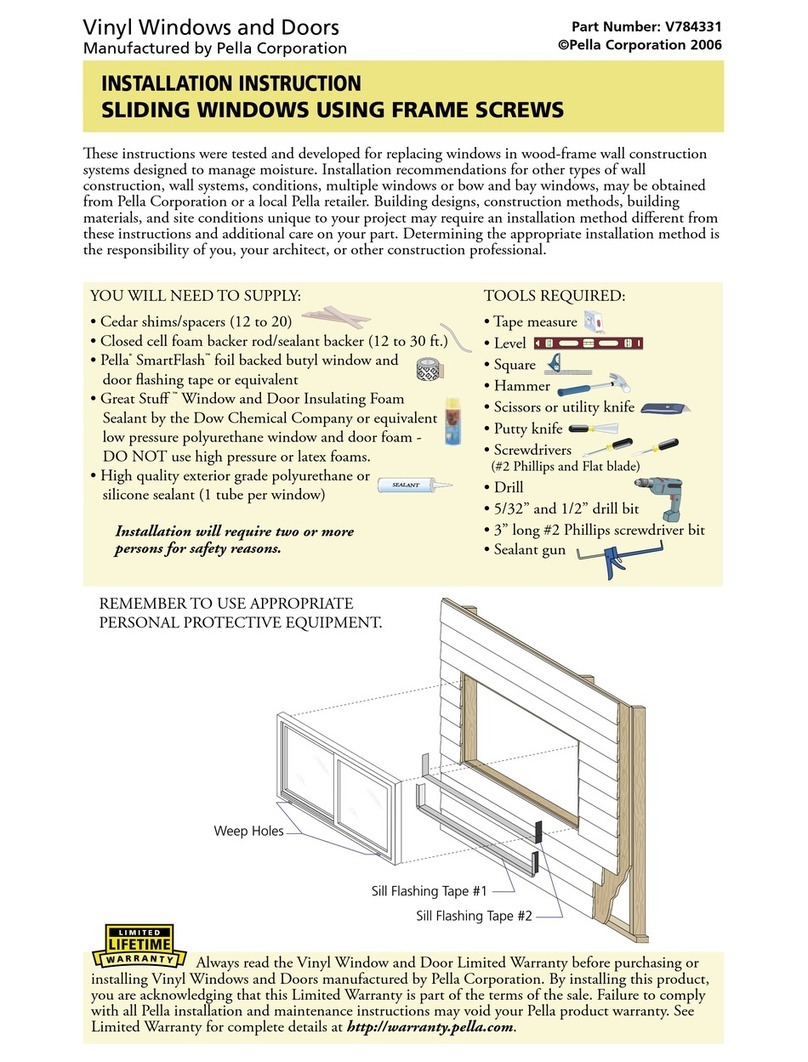

Always read the Vinyl Window and Door Limited Warranty before purchasing or

installing Vinyl Windows and Doors manufactured by Pella Corporation. By installing this product,

you are acknowledging that this Limited Warranty is part of the terms of the sale. Failure to comply

with all Pella installation and maintenance instructions may void your Pella product warranty. See

Limited Warranty for complete details at http://warranty.pella.com.

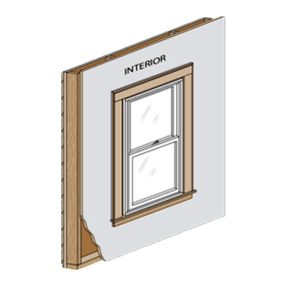

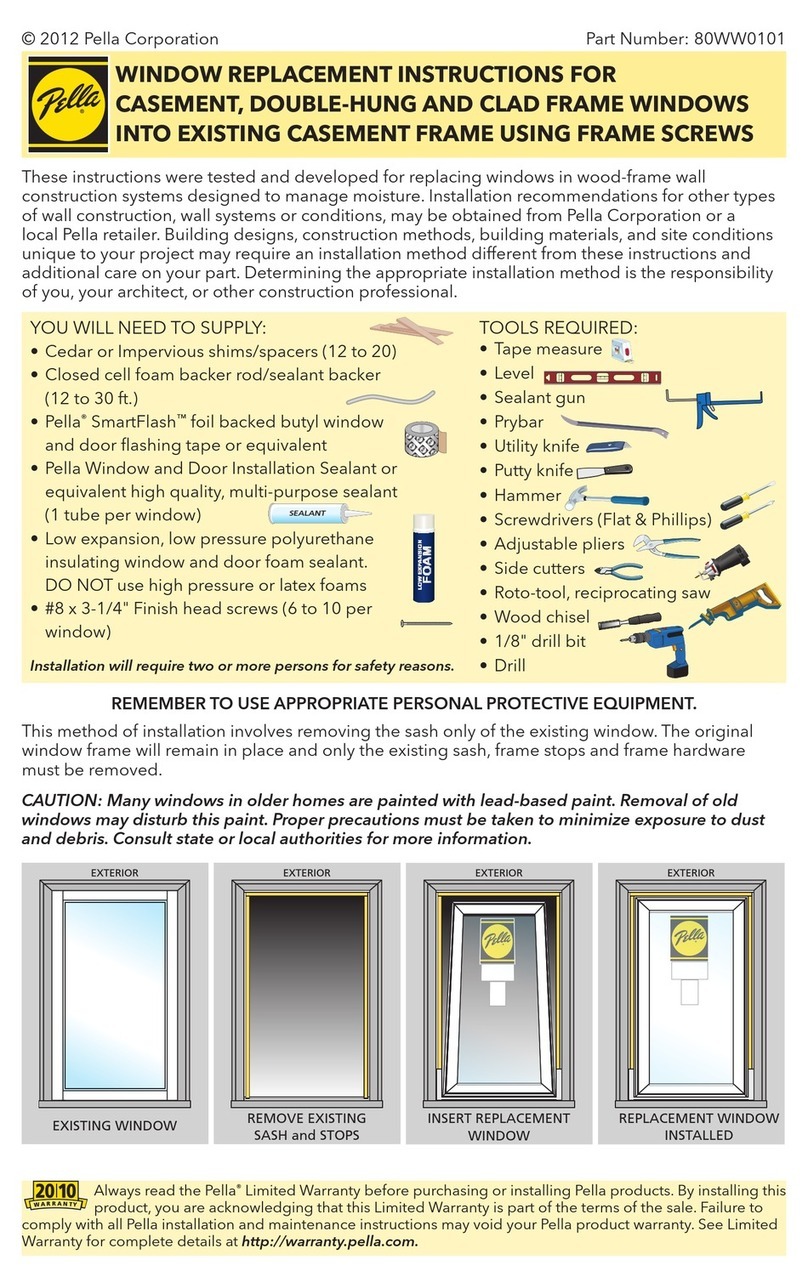

INSTALLATION INSTRUCTION - INSTRUCCIONES DE INSTALACION

FOR DOUBLE-HUNG VENT REPLACEMENT WINDOW

Part Number: V784840

©Pella Corporation 2007

Vinyl Windows and Doors

Manufactured by Pella Corporation

Lea las instrucciones en español en el reverso.

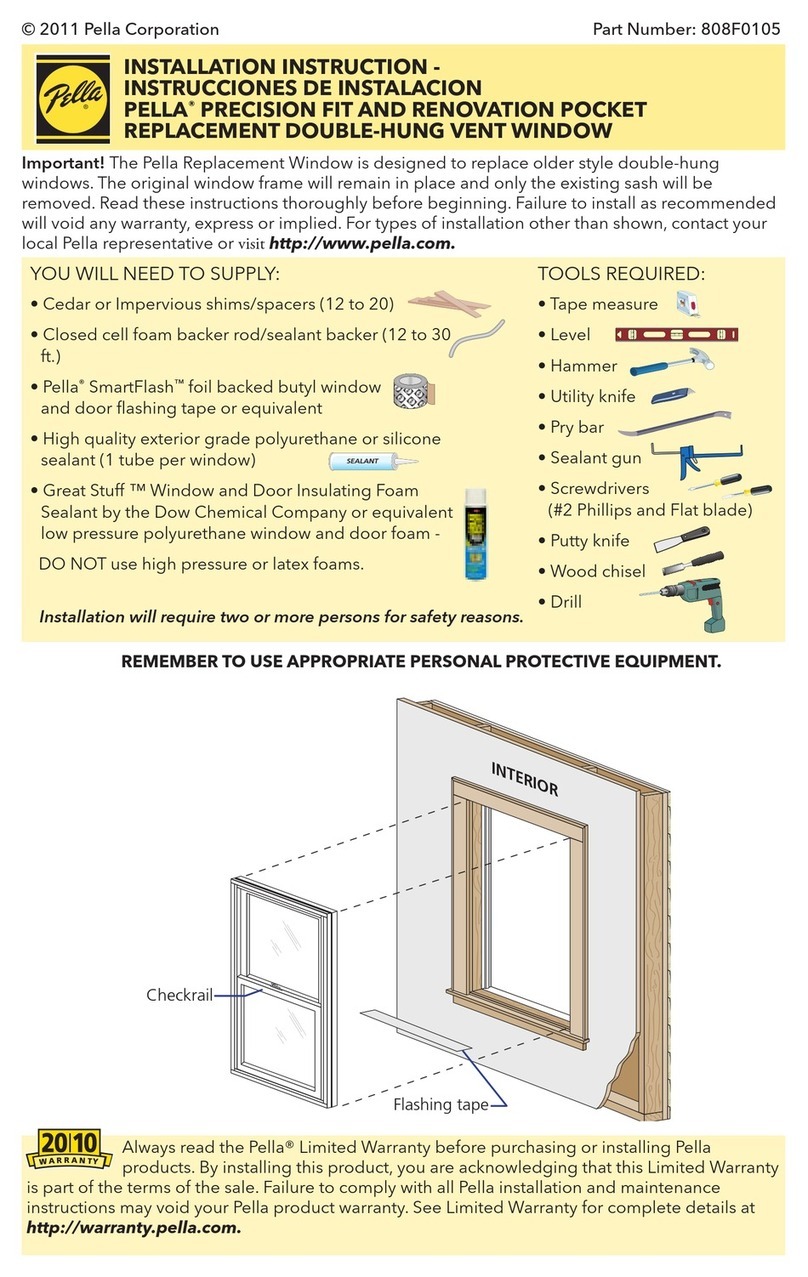

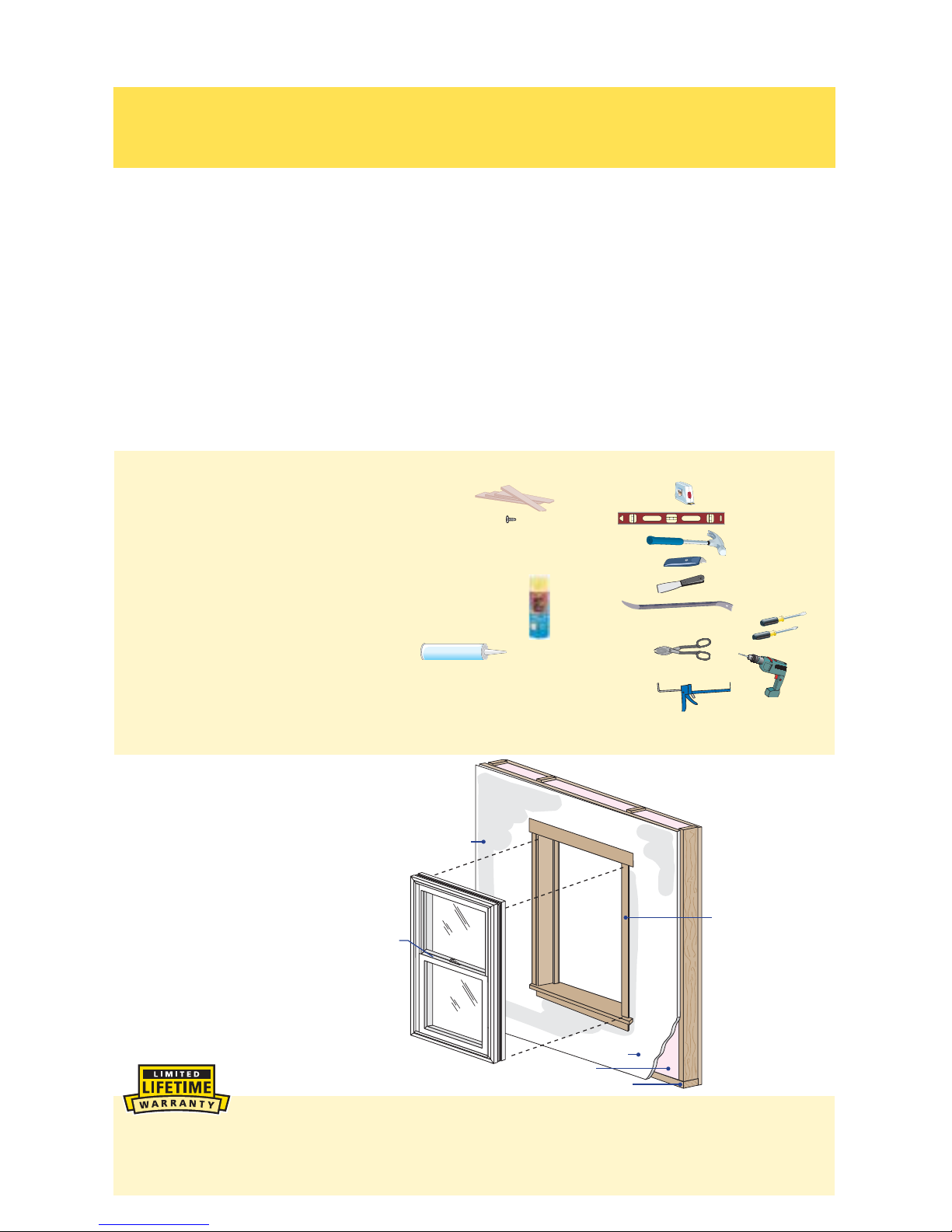

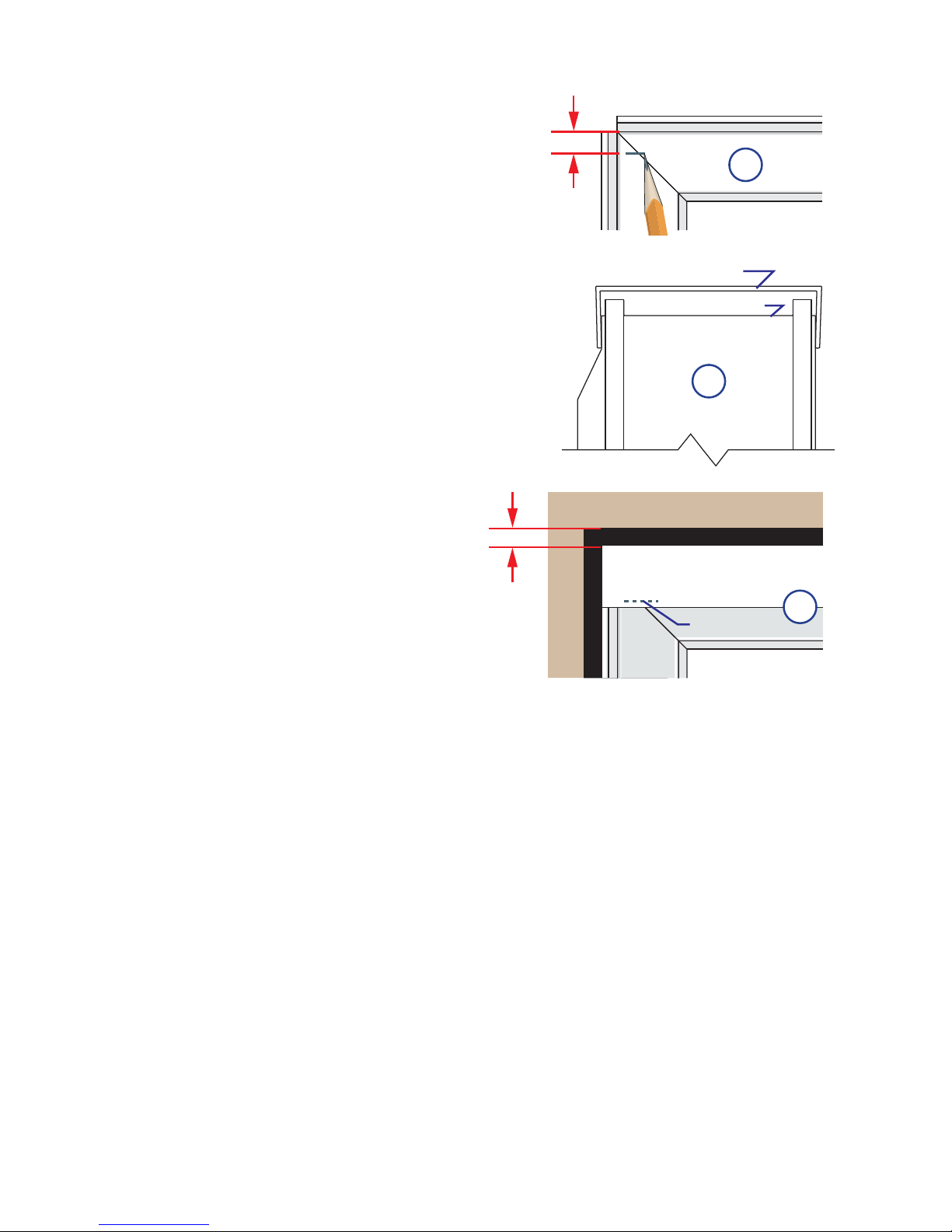

*OUFSJPS

%SZXBMM

&YJTUJOHXBMM

DPOTUSVDUJPO

&YJTUJOH

XJOEPX

GSBNF

*OTVMBUJPO

'SBNJOH

$IFDLSBJM

YOU WILL NEED TO SUPPLY: TOOLS REQUIRED:

s#EDAROR)MPERVIOUSSHIMSSPACERSTO

sXSHEETMETALSCREWSFORHEADEXPANDER

s'REAT3TUFF™Window and Door Insulating Foam

Sealant by the Dow Chemical Company or equivalent

LOWPRESSUREPOLYURETHANEWINDOWANDDOORFOAM

$/./4USEHIGHPRESSUREORLATEXFOAMS

s(IGHQUALITYEXTERIORGRADEPOLYURETHANEOR

SILICONESEALANTTUBEPERWINDOW

s,OOSElLLlBERGLASSINSULATION

s4APEMEASURE

s,EVEL

s(AMMER

s5TILITYKNIFE

s0UTTYKNIFE

s0RYBAR

s3CREWDRIVER&LAT0HILLIPS

s3IDECUTTERS

s$RILLWITHvDRILLBIT

s3EALANTGUN

Installation will require two or

more persons for safety reasons.

&OR(IGH0ERFORMANCE)NSTALLATIONSONLY

sXmATHEADCORROSIONRESISTANTWOODSCREWS

sXPINEFORINTERIORFRAMESTOPS

SEALANT

SEALANT