Part Number: 80YW0102

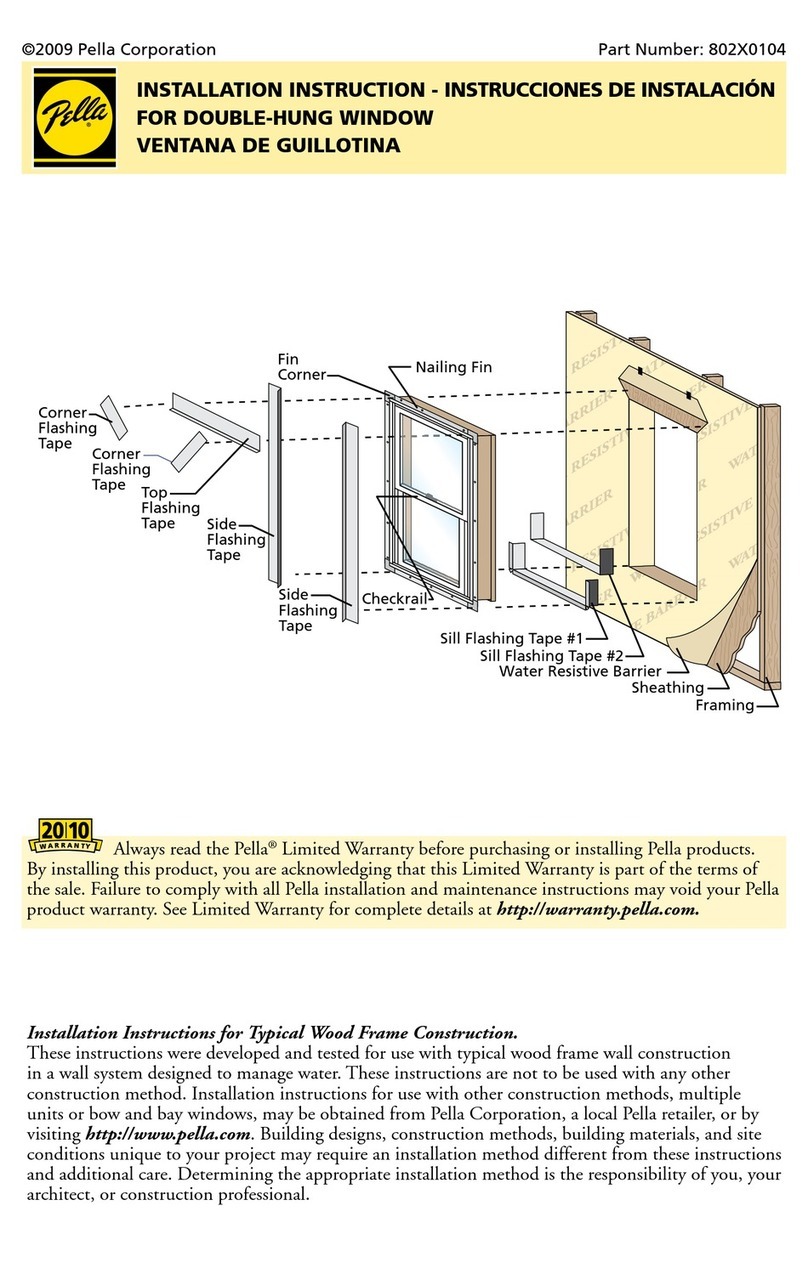

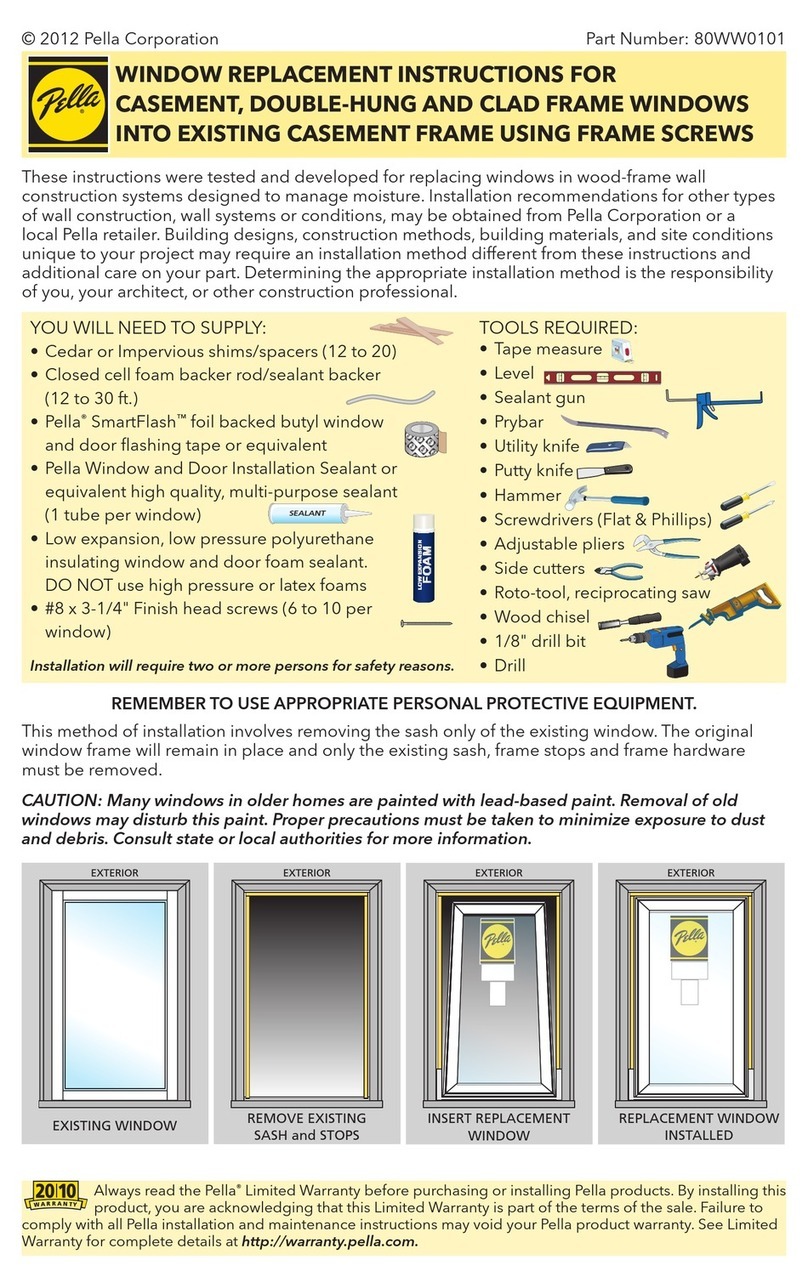

These instructions were tested and developed for replacing windows in wood-frame wall

construction systems designed to manage moisture. This method of installation involves removing

the sash, frame stops and frame hardware from the existing window. The original window frame

will remain in place. If existing window frame shows signs of water infiltration or is damaged

beyond repair, this method should not be followed and the entire existing window should

be removed. Installation recommendations for other types of wall construction, wall systems,

conditions, multiple windows or bow/bay windows, may be obtained from Pella Corporation or a

local Pella retailer. Building designs, construction methods, building materials, and site conditions

unique to your project may require an installation method different from these instructions and

additional care on your part. Determining the appropriate installation method is the responsibility

of you, your architect, or other construction professional.

Always read the Pella®Impervia®Limited Warranty before purchasing or

installing Pella Impervia products. By installing this product, you are acknowledging that this

Limited Warranty is part of the terms of the sale. Failure to comply with all Pella Impervia

installation and maintenance instructions may void your Pella Impervia product warranty. See

Limited Warranty for complete details at http://warranty.pellaimpervia.com.

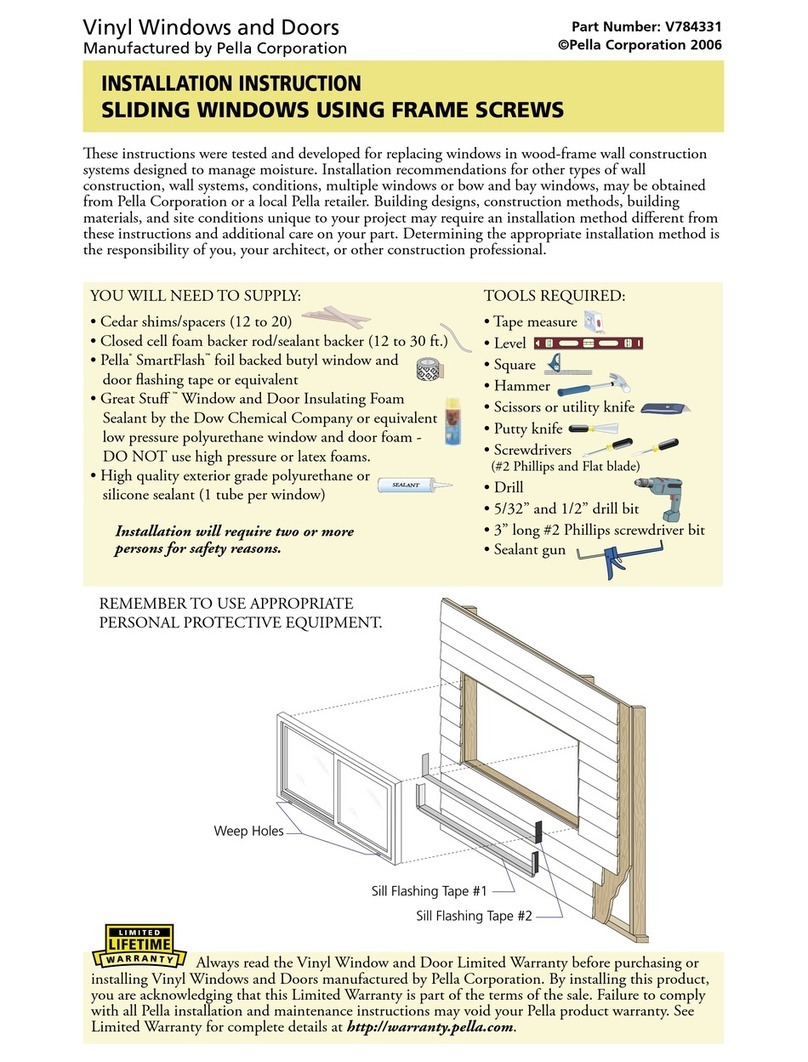

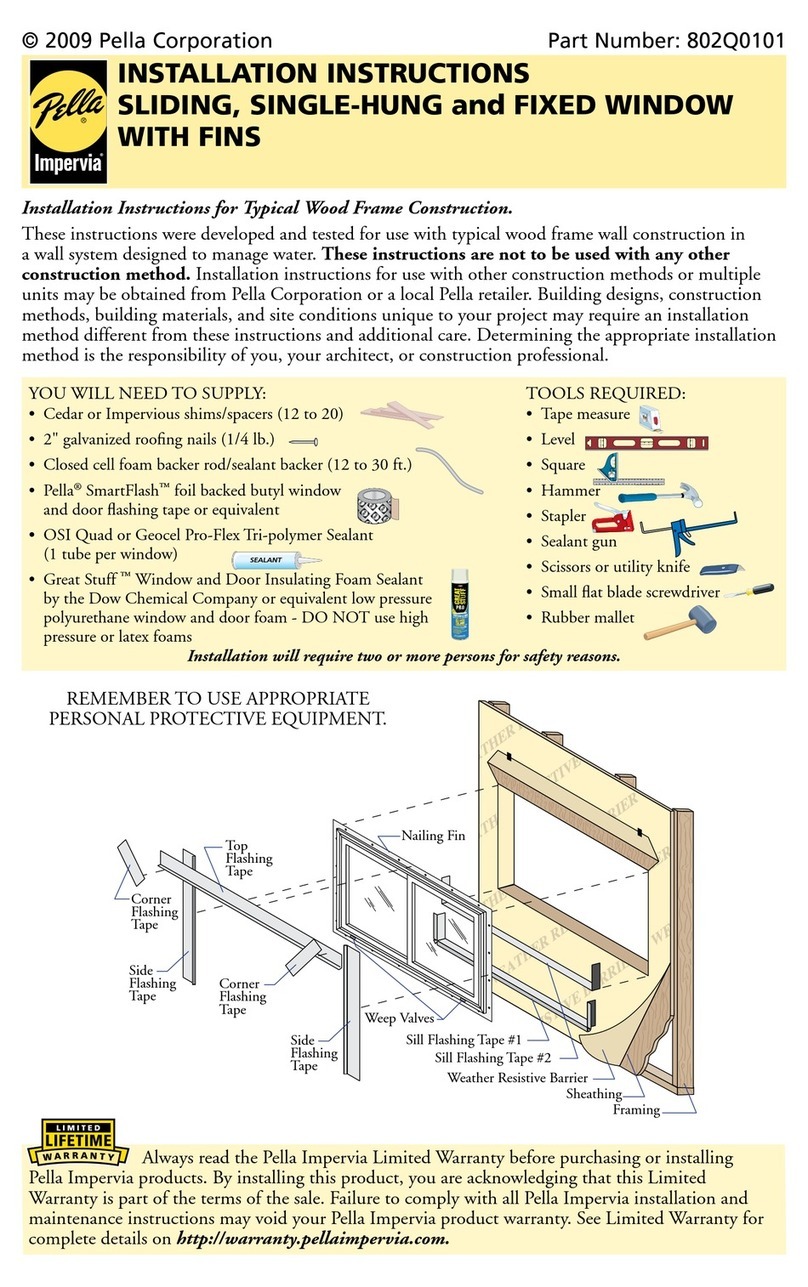

REMEMBER TO USE APPROPRIATE

PERSONAL PROTECTIVE EQUIPMENT.

CAUTION: Many windows in older

homes are painted with lead-based

paint. Removal of old windows may

disturb this paint. Proper precautions

must be taken to minimize exposure

to dust and debris. Consult state or

local authorities for more information.

4JMM"EBQUFS 'MBTIJOH5BQF

&95&3*03

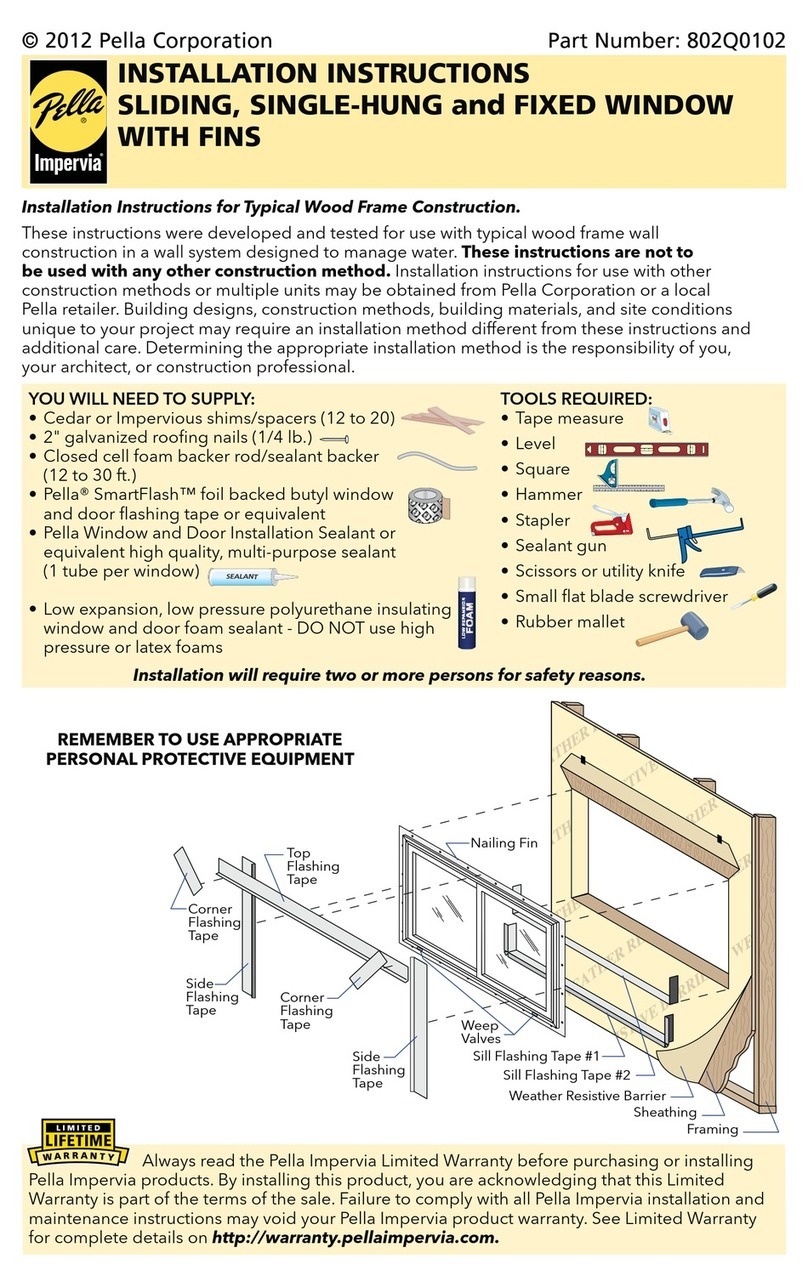

YOU WILL NEED TO SUPPLY:

Ř&HGDURU,PSHUYLRXVVKLPVVSDFHUVWR

Ř&ORVHGFHOOIRDPEDFNHUURGVHDODQWEDFNHU

WRIW

Ř3HOOD®SmartFlash™foil backed butyl window

and door flashing tape or equivalent

Ř3HOOD:LQGRZDQG'RRU,QVWDOODWLRQ6HDODQWRU

equivalent high quality, multi-purpose sealant

WXEHSHUZLQGRZ

Ř/RZH[SDQVLRQORZSUHVVXUHSRO\XUHWKDQH

insulating window and door foam sealant. DO

NOT use high pressure or latex foams

Ř[:RRGVFUHZVWRSHUZLQGRZ

Ř3HOODUHSODFHPHQWZLQGRZVLOODGDSWHU

TOOLS REQUIRED:

Ř7DSHPHDVXUH

Ř/HYHO

Ř6HDODQWJXQ

Ř3U\EDU

Ř8WLOLW\NQLIH

Ř3XWW\NQLIH

Ř+DPPHU

Ř6FUHZGULYHUV)ODW3KLOOLSV

Ř$GMXVWDEOHSOLHUV

Ř6LGHFXWWHUV

Ř5RWRWRROUHFLSURFDWLQJVDZ

Ř:RRGFKLVHO

ŘGULOOELW

Ř'ULOO

Installation will require two or more persons for safety reasons.

4&"-"/5

4&"-"/5

©2009 Pella Corporation

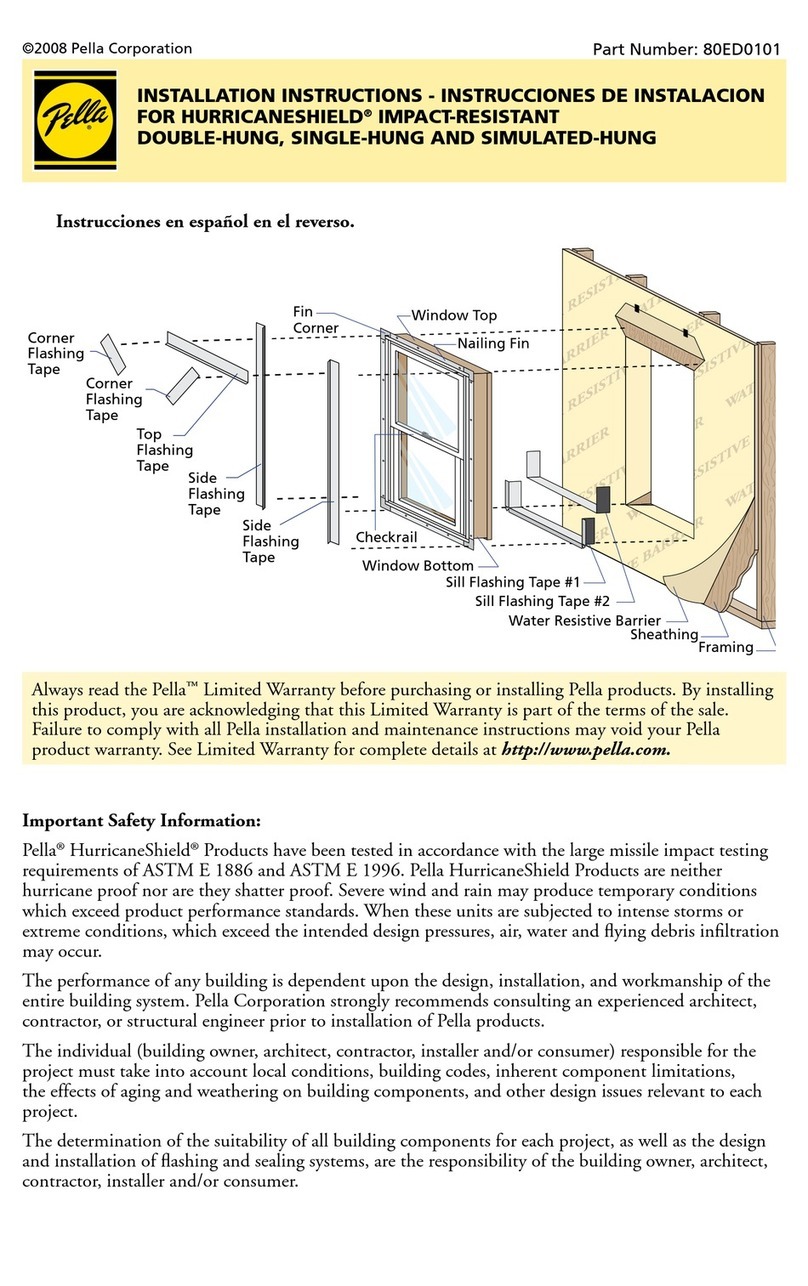

WINDOW REPLACEMENT INSTRUCTIONS FOR SINGLE-HUNG,

DOUBLE-HUNG, CASEMENT, AWNING

INTO EXISTING

DOUBLE-HUNG FRAME USING FRAME SCREWS FROM THE EXTERIOR