7COLDRINK -7CLM+SERIES SYSTEMS INSTALLATION AND OPERATION GUIDE

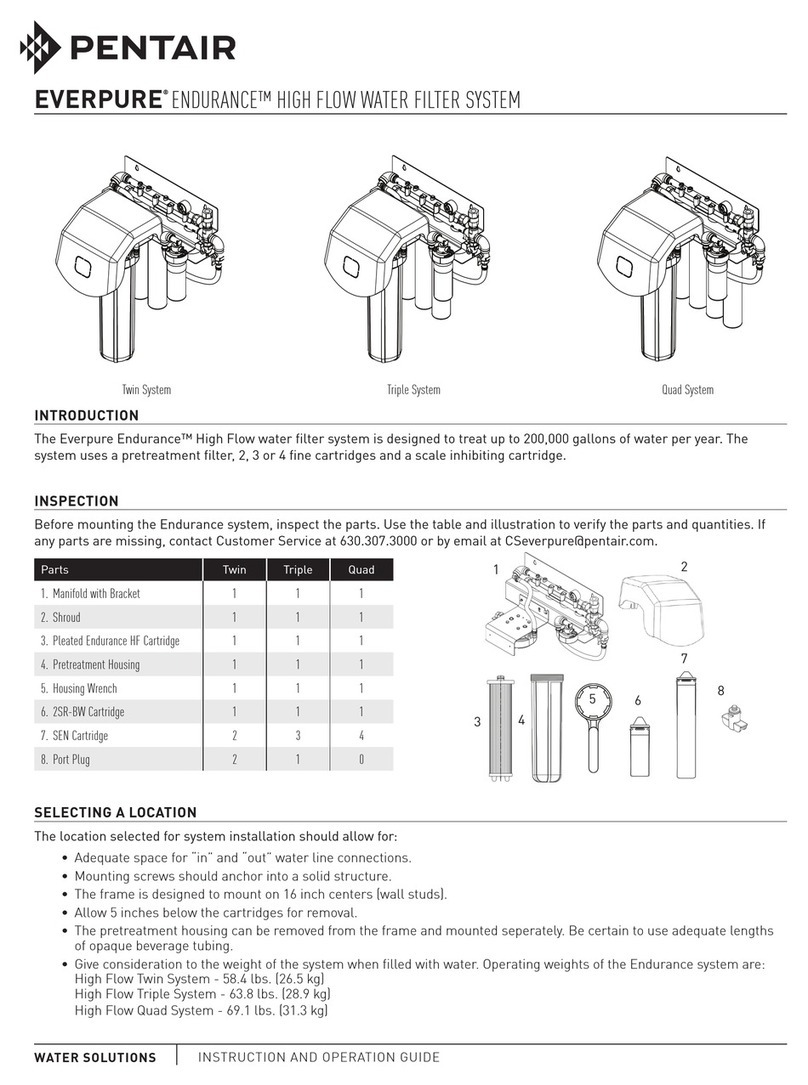

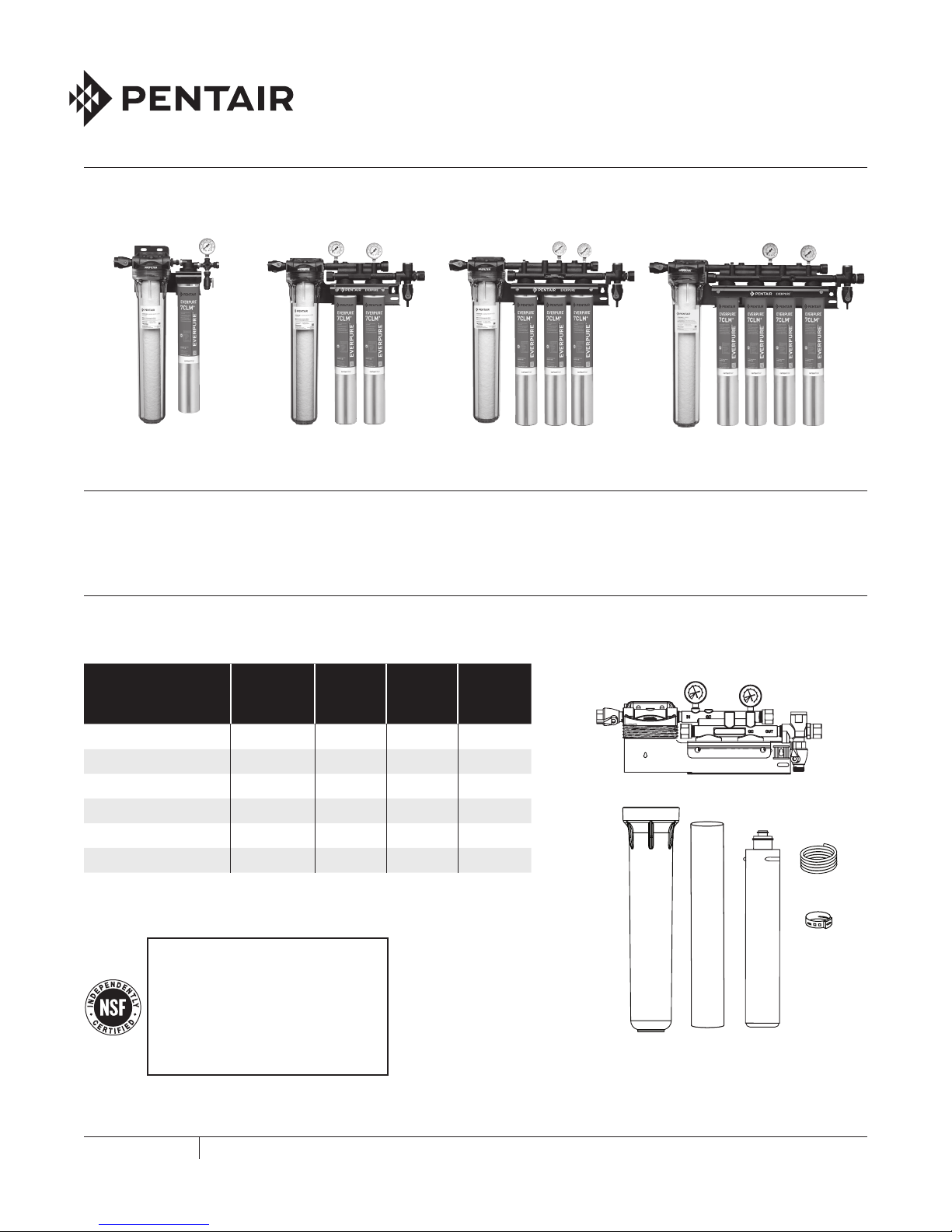

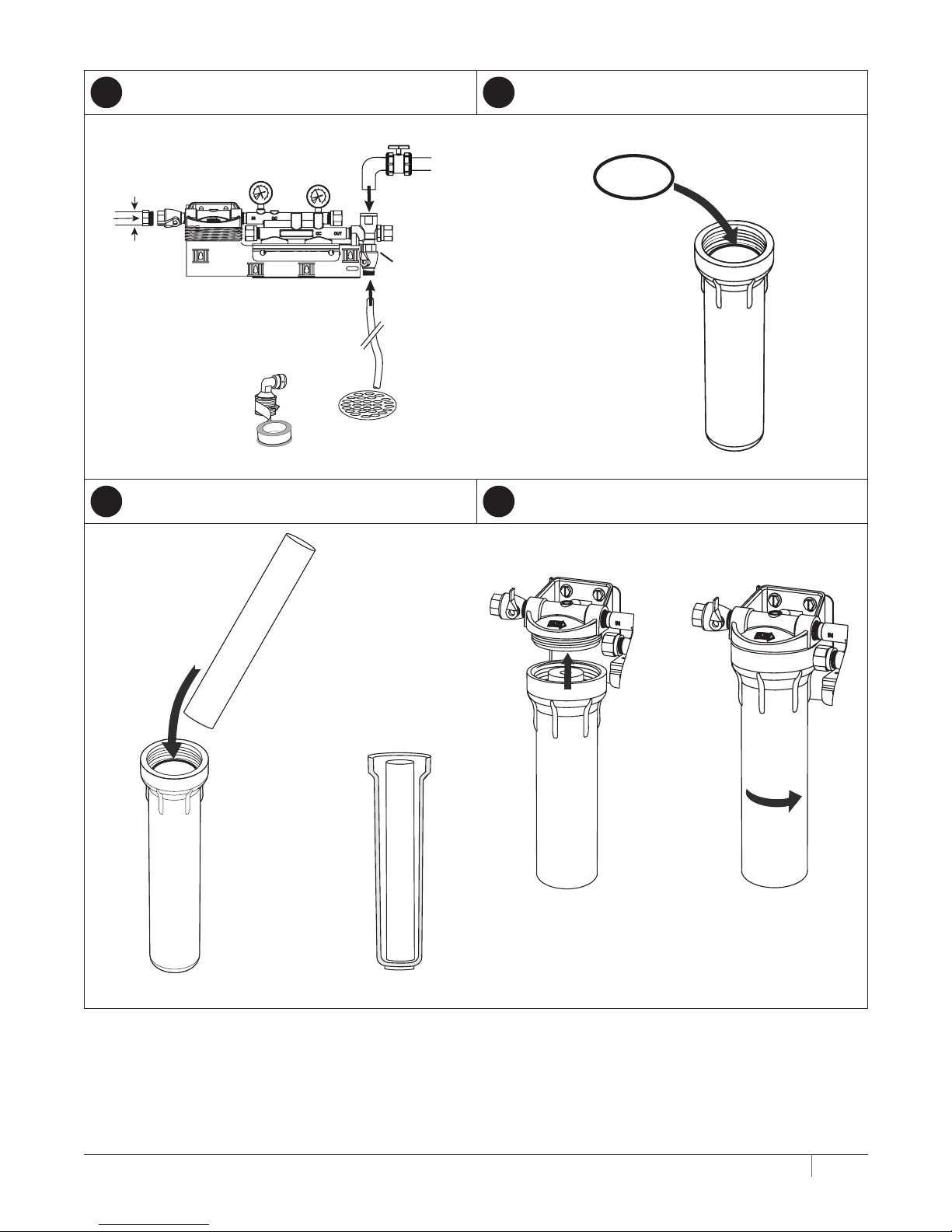

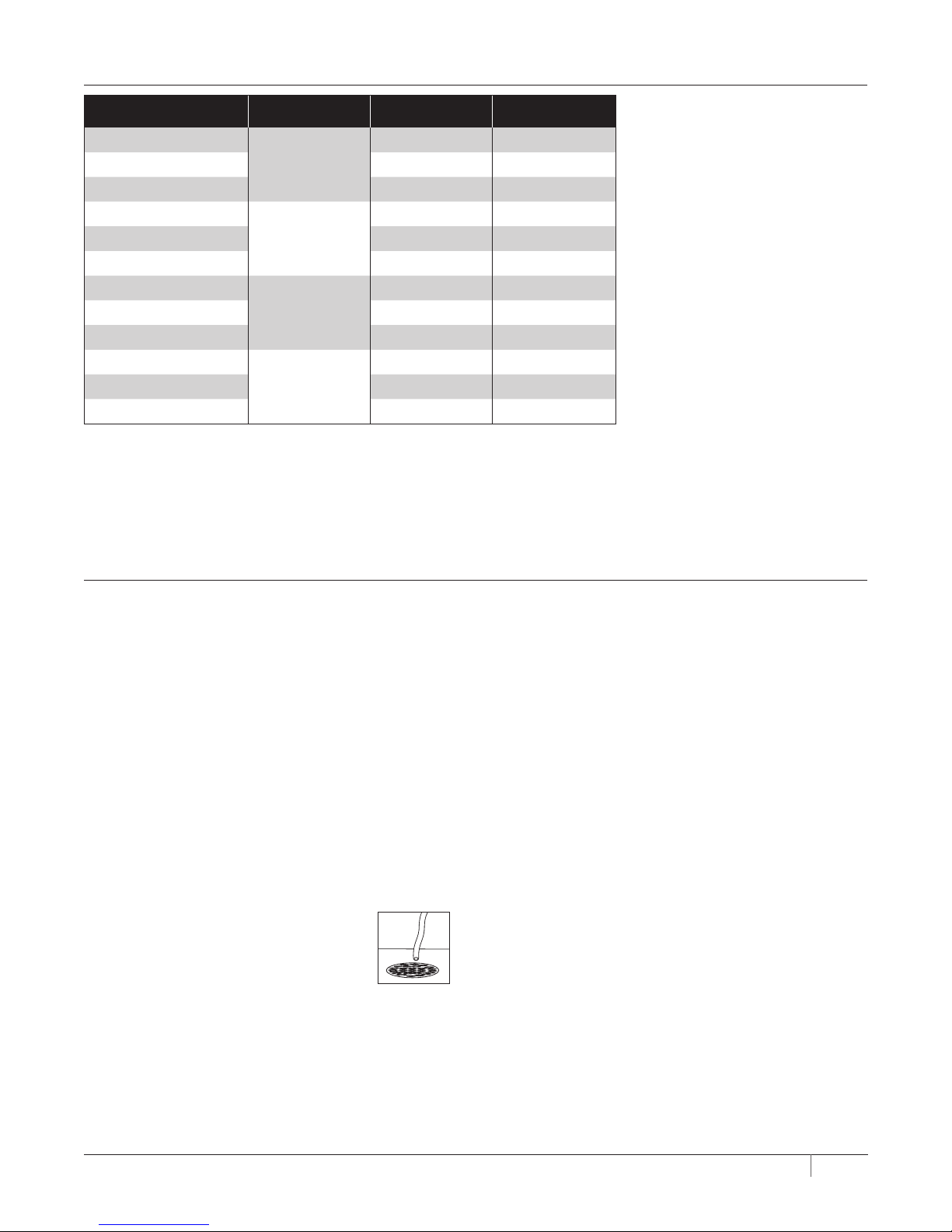

OPERATING SPECIFICATIONS*

Combined Model Name Part Number Flow Rate Capacity

Coldrink System 1 - 7CLM+

EV9771-21

1.67 gpm (6.32 Lpm) 7,500 gals (28,390 L)

Coldrink System 1 - 7CLM+1.33 gpm (5.03 Lpm)†9,500 gals (35,961 L)†

Coldrink System 1 - 7CLM+1.00 gpm (3.78 Lpm)†12,600 gals (47,696 L)†

Coldrink System 2 - 7CLM+

EV9771-22

3.34 gpm (12.64 Lpm) 15,000 gals (56,781 L)

Coldrink System 2 - 7CLM+2.66 gpm (10.06 Lpm)†19,000 gals (71,922 L)†

Coldrink System 2 - 7CLM+2.00 gpm (7.57 Lpm)†25,200 gals (95,392 L)†

Coldrink System 3 - 7CLM+

EV9771-23

5.01 gpm (18.96 Lpm) 22,500 gals (85,171 L)

Coldrink System 3 - 7CLM+4.00 gpm (15.14 Lpm)†28,500 gals (107,884 L)†

Coldrink System 3 - 7CLM+3.00 gpm (11.35 Lpm)†37,800 gals (143,088 L)†

Coldrink System 4 - 7CLM+

EV9771-24

6.68 gpm (25.29 Lpm) 30,000 gals (113,562 L)

Coldrink System 4 - 7CLM+5.33 gpm (20.17 Lpm)†38,000 gals (143,845 L)†

Coldrink System 4 - 7CLM+4.00 gpm (15.14 Lpm)†50,400 gals (190,784 L)†

*For individual cartridge specifications, refer to cartridge literature.

†Not Performance Tested or Certified by NSF.

Temperature: 35 - 100°F (2 - 38°C)

Pressure: 10 -125 psi (0.7 - 8.6 bar), non-shock

For cold water use only.

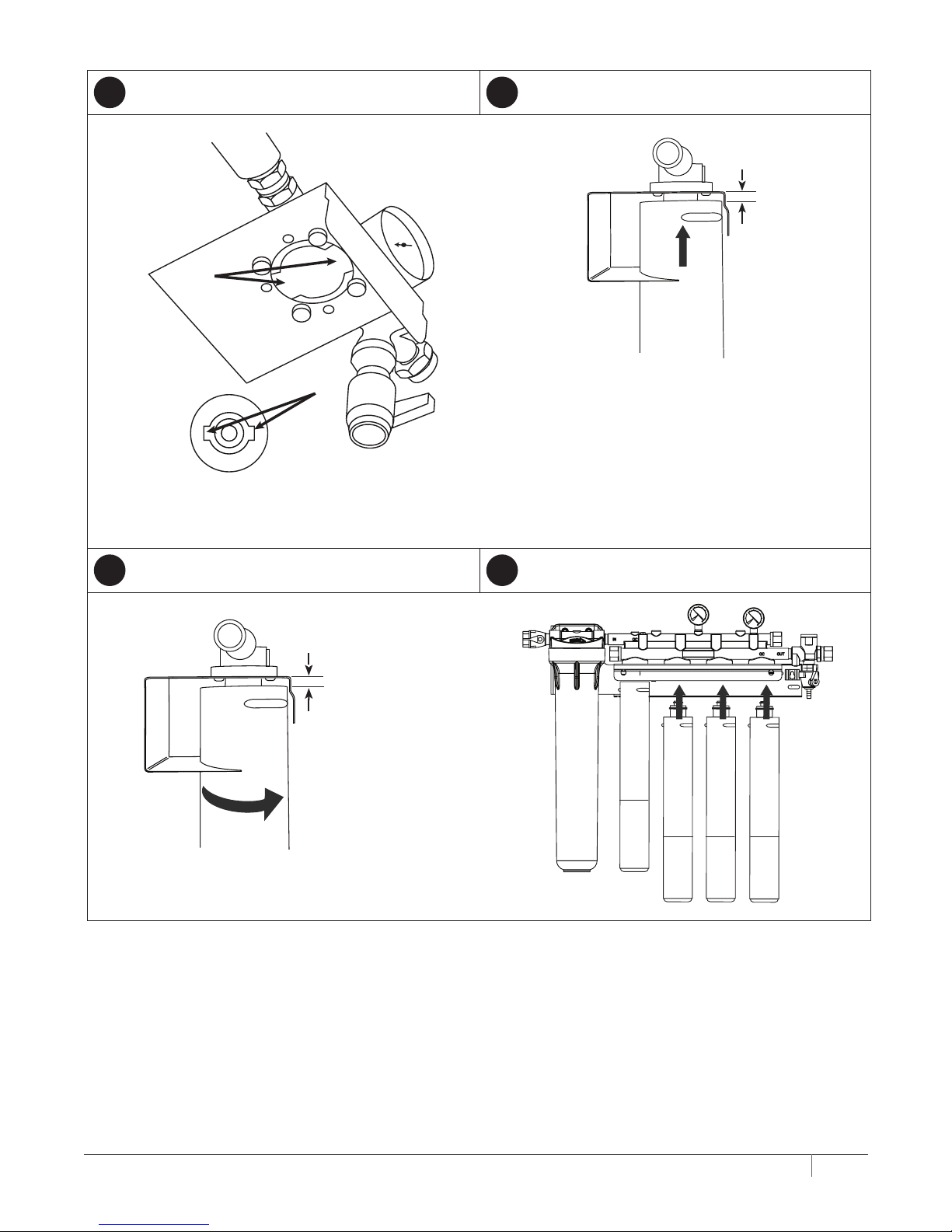

INSTALLATION

1. Use the predrilled mounting holes in the manifold bracket

as guides. Mark and drill anchor hole. Mount securely.

2. Shut off power to equipment.

3. Connect outlet port of Coldrink - 7CLM+Series System to

the equipment served. Always use an NSF-approved pipe

dope or plumbers tape at all connections. Use a backup

wrench on all fittings while connecting to avoid excessive

stress on the system components.

4. Install a manual shut-off valve leading to the system

for servicing.

5. Connect inlet water line to inlet valve of Coldrink – 7CLM+

Series Systems. Connect a minimum of 1/2" water line to

the Single Coldrink - 7CLM+ Series System for flushing.

All other manifolds use a 3/4-inch water line.

6. Connect tubing to the flushing valve and run to drain. The

cross fitting has a flushing valve installed on the bottom.

NOTE: Some municipal plumbing codes

and good sanitary practices

require an air gap at the drain

termination point.

Air Gap

7. Shut off the system inlet valve located on the inlet of the

prefilter head.

8. Check to be sure the o-ring on the prefilter housing

is sufficiently lubricated. Use a good grade of silicone

lubricant, if needed. Position the prefilter cartridge on

guide seat in the bottom of the bowl. Then thread the

bowl into the head by hand. Use a sump wrench to snug

the bowl onto the head.

9. Install the carbon filter cartridge(s) into the filter head(s)

following directions on the cartridge label or as shown in

the Cartridge Change Procedure section illustrations.

CAUTION: Unused manifold ports must be plugged. Any

ports not plugged will leak.

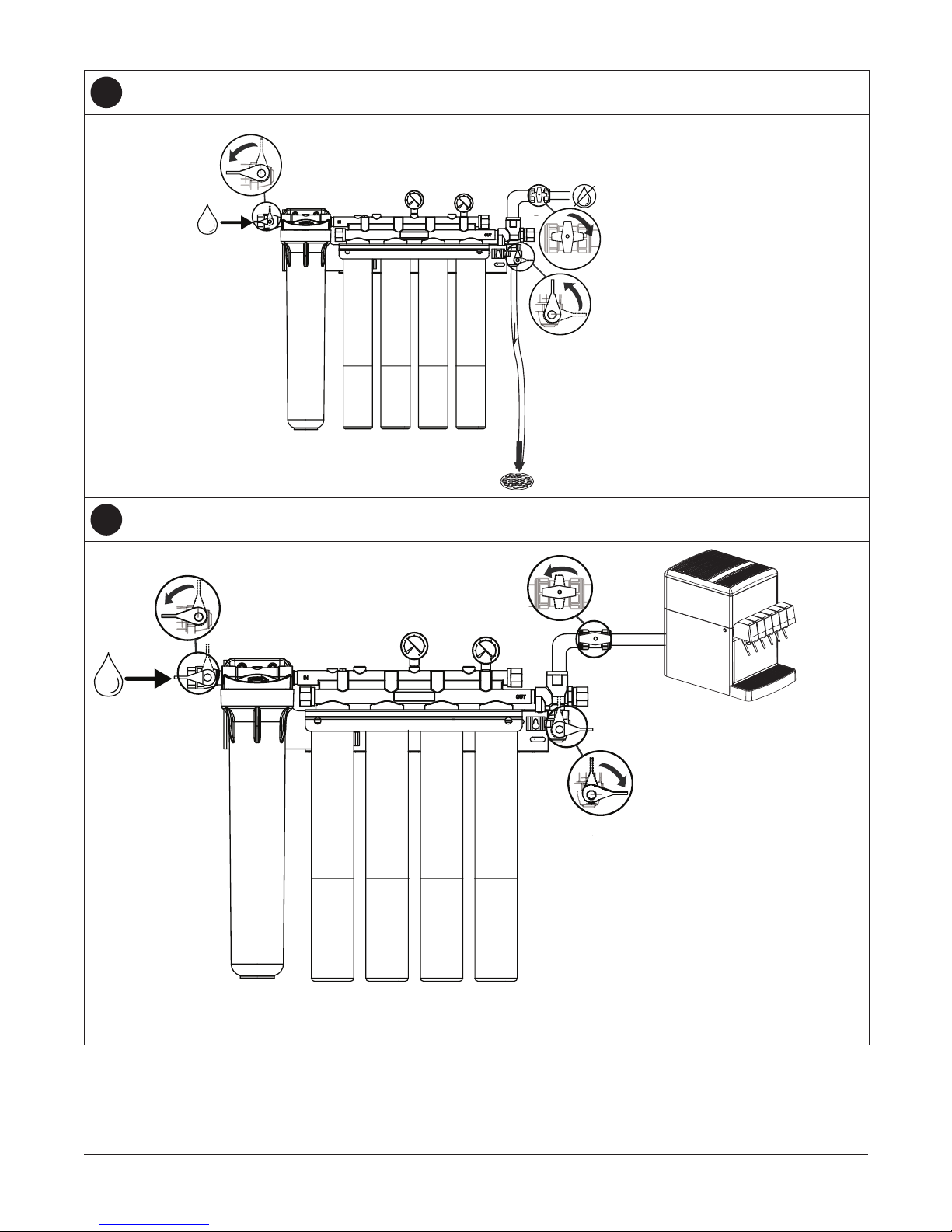

10. Turn on inlet water to the filter system and check for leaks.

11. Open the flushing valve and flush the newly installed

cartridge(s) by running feed water for five (5) minutes at

full flow or a minimum of 25 gallons (94.6 liters) through

flush port. This procedure will help set the filtering

media and purge any air and fines, ensuring maximum

filter life.

12. Disconnect the outlet line and flush one (1) gallon (3.8

liters) of water through the outlet. This will clear any

fines that may have entered through the outlet from the

previous flushing procedure. This is only applicable on

the first installation of the system, or when there is air

trapped in the outlet line due to maintenance.

13. After flushing, close the flushing valve, turn on power

to equipment, and plug the EverguardTM Low Pressure

Alarm (LPA), if so equipped, into the electrical outlet. The

system is ready for operation.