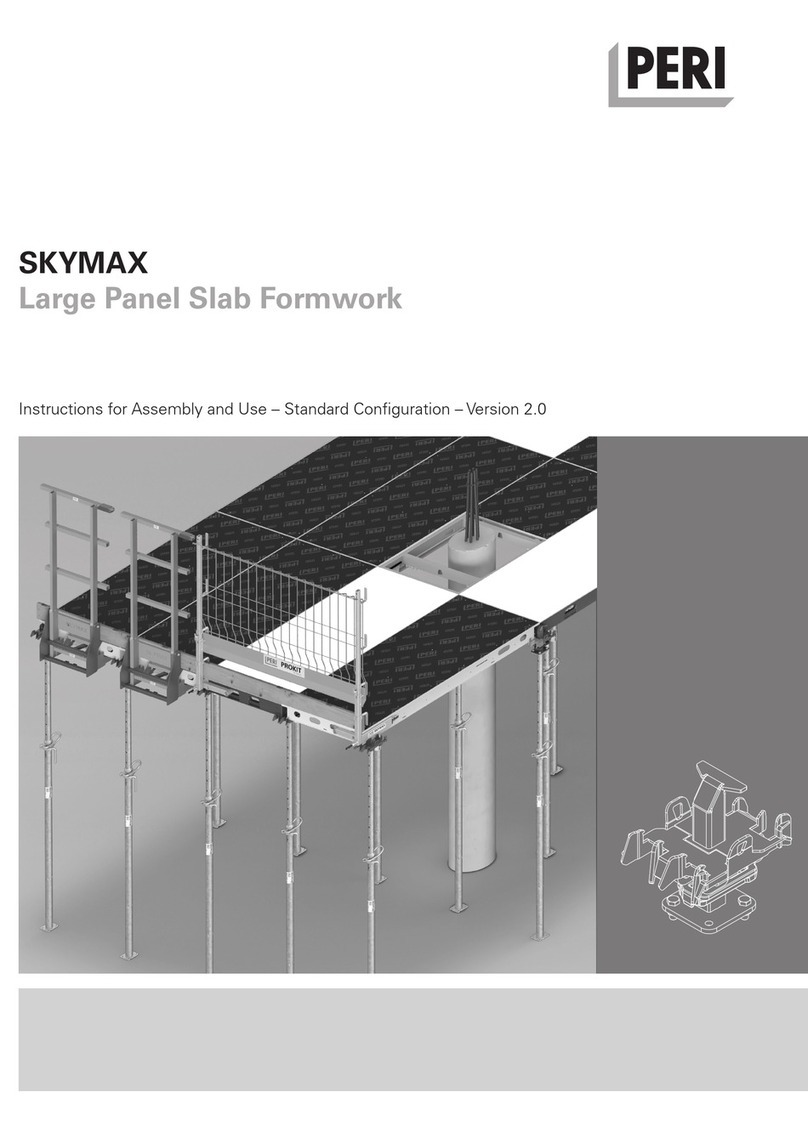

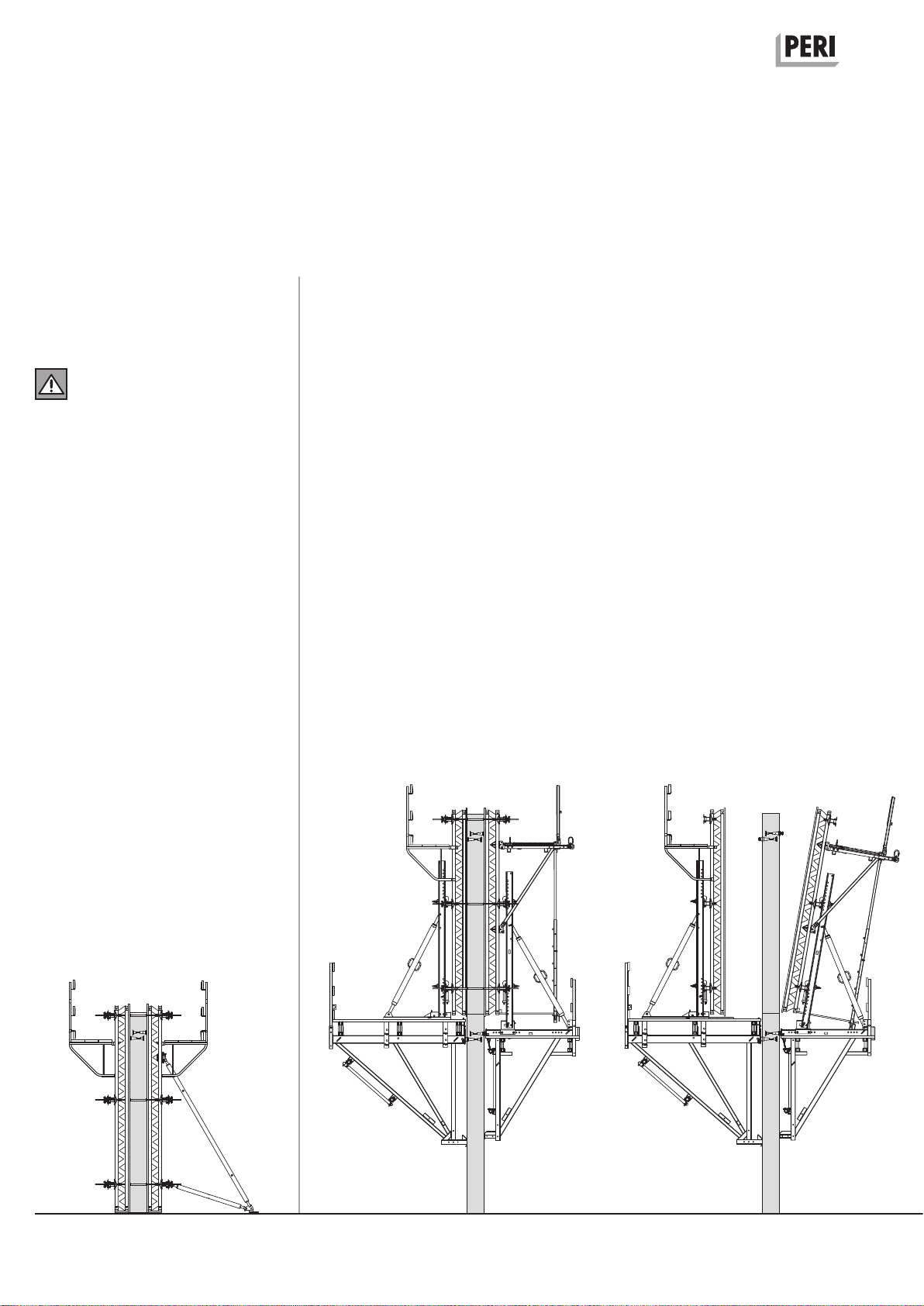

4Instructions for Assembly and Use – Standard Configuration

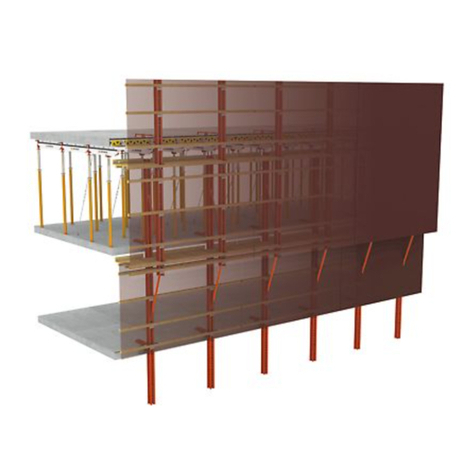

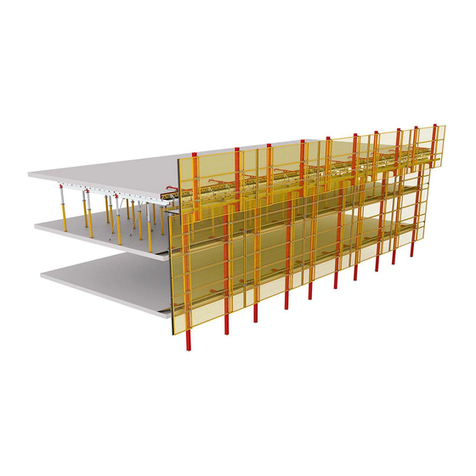

CB 160 Climbing Formwork

Introduction

Safety Instructions

General

1. Deviations from the standard configu-

ration and/or intended use present a

potential safety risk.

2. All country-specific laws, standards

and other safety regulations are to be

taken into account whenever our prod-

ucts are used.

3. During unfavourable weather condi-

tions, suitable precautions and meas-

ures are to be taken in order to ensure

both working safety and stability.

4. The contractor (user) must ensure

the stability throughout all phases of

construction. He must ensure and veri-

fy that all loads occuring are safely

transferred.

5. The contractor (user) has to provide

safe working areas for site personnel

which can be safely accessed. Areas of

risk must be cordoned off and clearly

marked. Hatches and openings on

accessible working areas must be kept

closed during working operations.

6. For better comprehensibility, detailed

drawings are partly incomplete. The

safety installations which have possibly

not been featured in these detailed

drawings must nevertheless be available.

Storage and Transportation

1. Do not drop the components.

2. Store and transport components en-

suring that no unintentional change in

their position is possible. Detach lifting

gear from the lowered units only if they

are in a stable position and no uninten-

tional change is possible.

3. When moving the components, make

sure they are lifted and set down in a

way that any unintentional tilting over,

falling apart, sliding or rolling away is

prevented.

4. Use only suitable load-carrying equip-

ment to move the components as well

as the designated load-bearing points.

5. During the lifting and moving proce-

dure, ensure that all loose parts are re-

moved or secured.

6. During the moving procedure always

use a guide rope.

7. Move components on clean, flat and

sufficiently load-bearing surfaces only.

System-specific

1. Retract components only when the

concrete has sufficiently hardened and

the person in charge has given the ap-

proval for striking to take place.

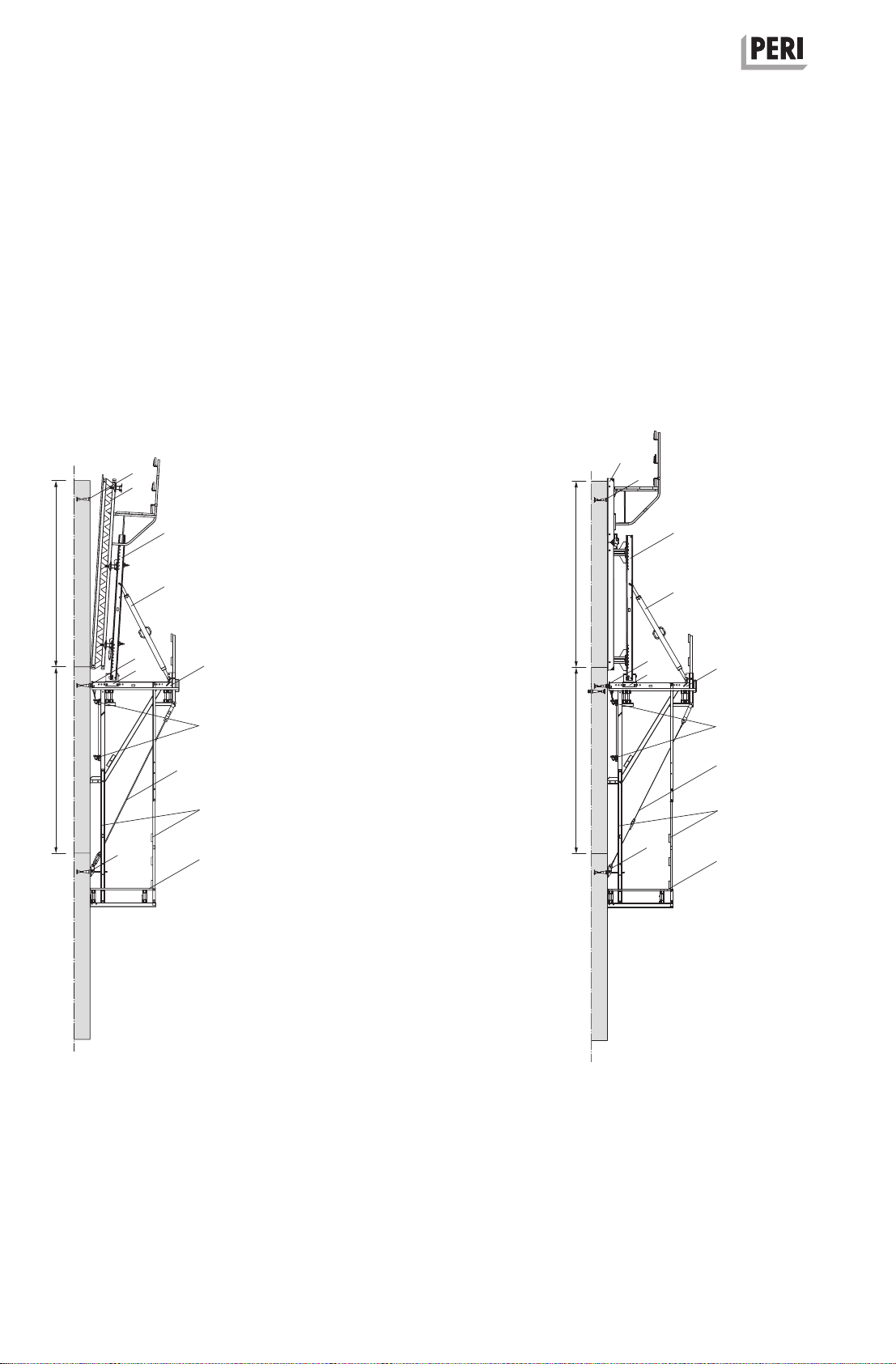

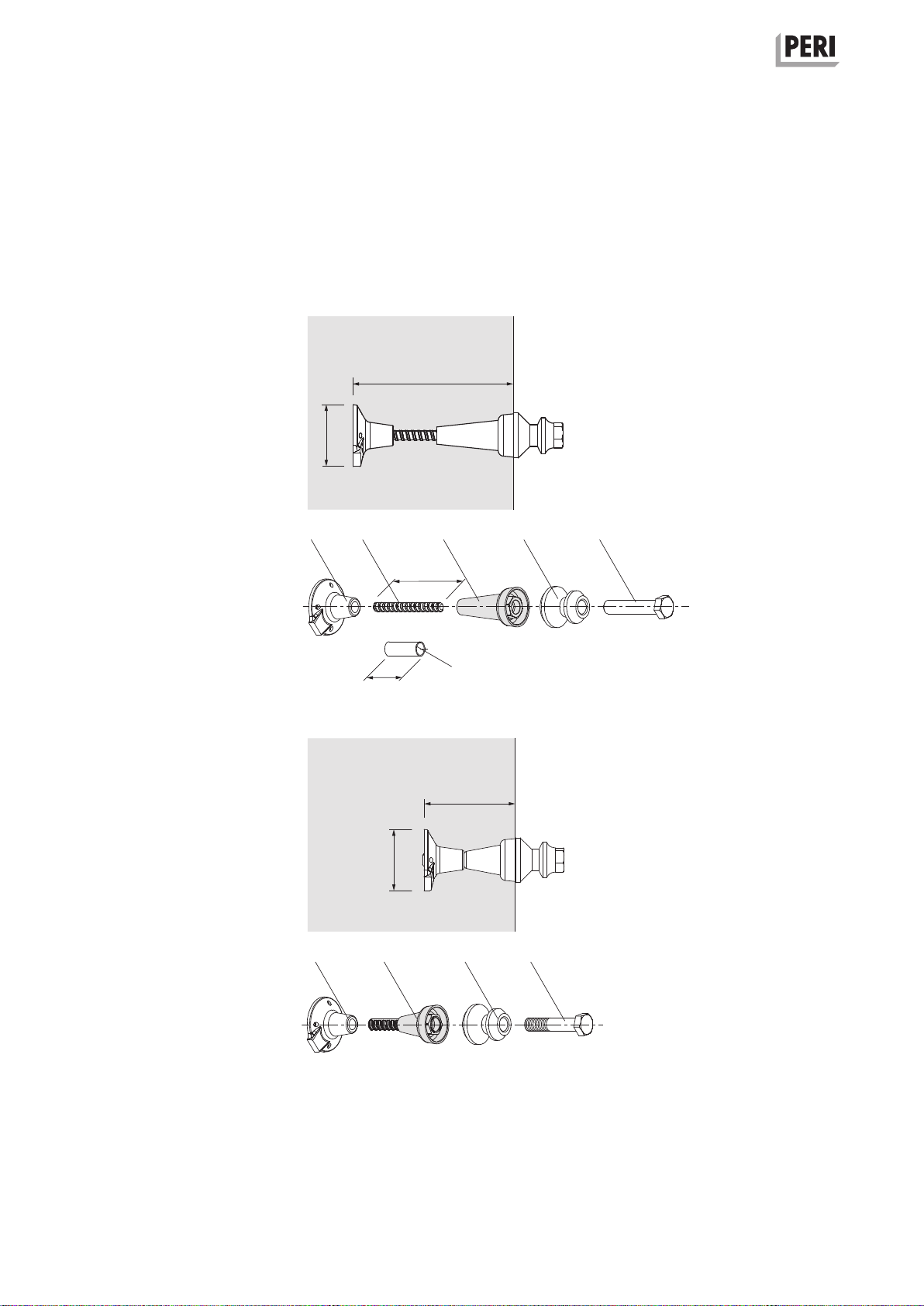

2. Anchoring is to take place only if the

anchorage has sufficient concrete

strength.

3. It is the responsibility of the contrac-

tor (user) to inspect all anchors and as-

sociated components.

4. Enclosure of the platform or mount-

ing of additional surfaces which are ex-

posed to the influences of the wind

changes the stability and must there-

fore be checked. If necessary, addition-

al measures must be implemented.

5. The platforms are to be inspected for

signs of damage by authorised person-

nel at regular intervals. Dirt which af-

fects the functionality is to be removed

immediately.

6. As a result of the moving procedure,

falling edges are formed between the

platforms. Corresponding areas are to

be secured.

7. Site personnel, construction materi-

als or tools may not be transported

while the scaffold unit is being moved

with the crane. Exceptions to this can

be determined through the operational

working and instructions for assembly

and use.

The assemblies shown in these PERI

Instructions for Assembly and Use are

only examples which feature only one

component size. They are valid for all

component sizes contained in the

standard configuration.

Additional PERI product information

– Type Test CB 160

– Brochure “Climbing System CB 240

and CB 160”

– Instructions of Use for the Crane

Splice 24

General

– Instructions for Use: Lifting Hook

MAXIMO 1.5 t

– PERI Design Tables for Formwork

Technology