3

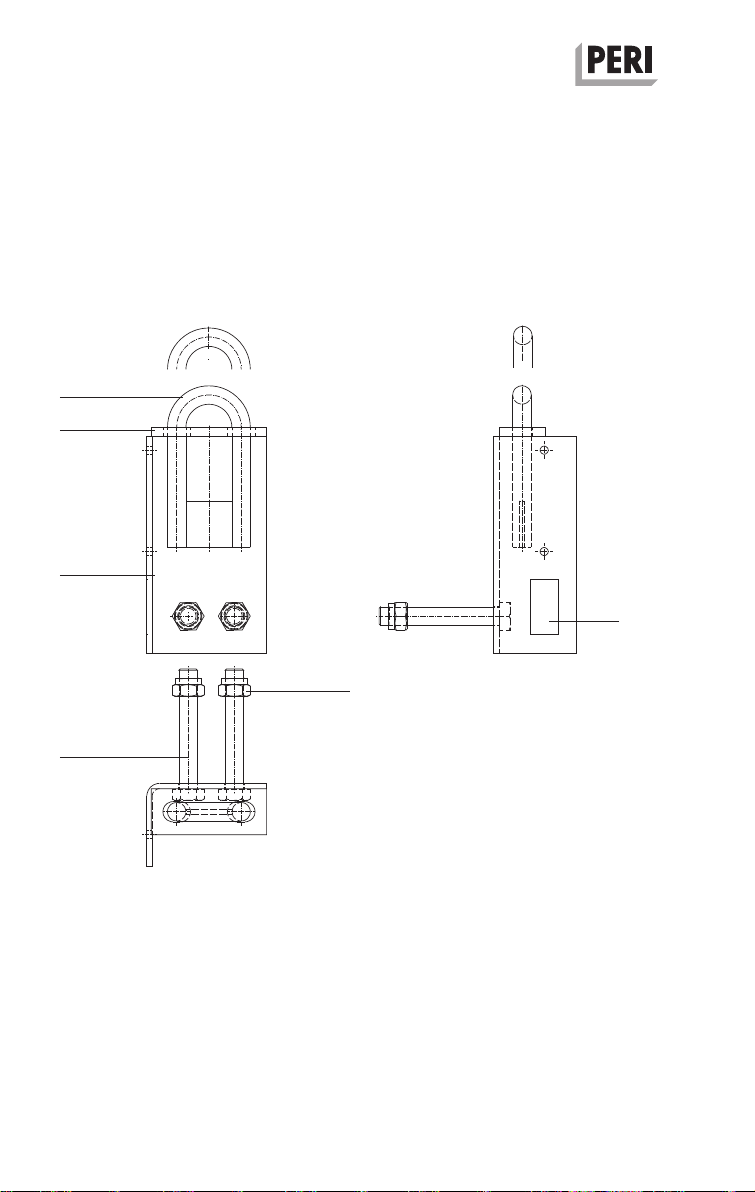

Platform Connection CB 160

Introduction

Translation of the Original Instructions for Use

Product-specific

The person who attaches the load to the

load-carrying equipment must be suffi-

ciently secured against falling. In all cas-

es, the load must be secured against

falling over and sliding!

Move loads only during the presence of

safe wind forces. Observe storm warn-

ings! Depending on the type of load and

the surface area subjected to wind at-

tack, the decision whether sufficient

safety is in place when moving the load

is taken at the time on the jobsite.

Use the specified load-carrying equip-

ment for moving loads. Before each lift-

ing procedure begins, check that the

load is securely connected to the lifting

gear.

Ensure loads are evenly balanced when

being picked up! Loads must be suffi-

ciently stable both in their form and

position so that the load does not move

during transportation!

Ensure that the load is in a safe and

secure position before releasing the

load-carrying equipment!

Always lift up or set down loads

smoothly without any jerking!

Safety Instructions

Before moving, remove or secure any

loose components!

Ensure that the steel wire rope or chains

are free of knots! Ensure that the lifting

chains of the load-carrying equipment

are not wrapped around the load to be

transported nor stretched over sharp

edges! Twisted chains must be straight-

ened!

Transporting persons on the load is pro-

hibited!

Components provided by the contractor

must meet site-related requirements

and comply with all applicable laws and

standards.

– Timber components: Strength Class

C24 for Solid Wood according to

EN 338.

– Scaffold tubes: galvanised steel tubing

with minimum dimensions

Ø 48.3 x 3.2 mm according to

EN12811-1:2003 4.2.1.2.

– Scaffold tube couplings according to

EN 74.