6

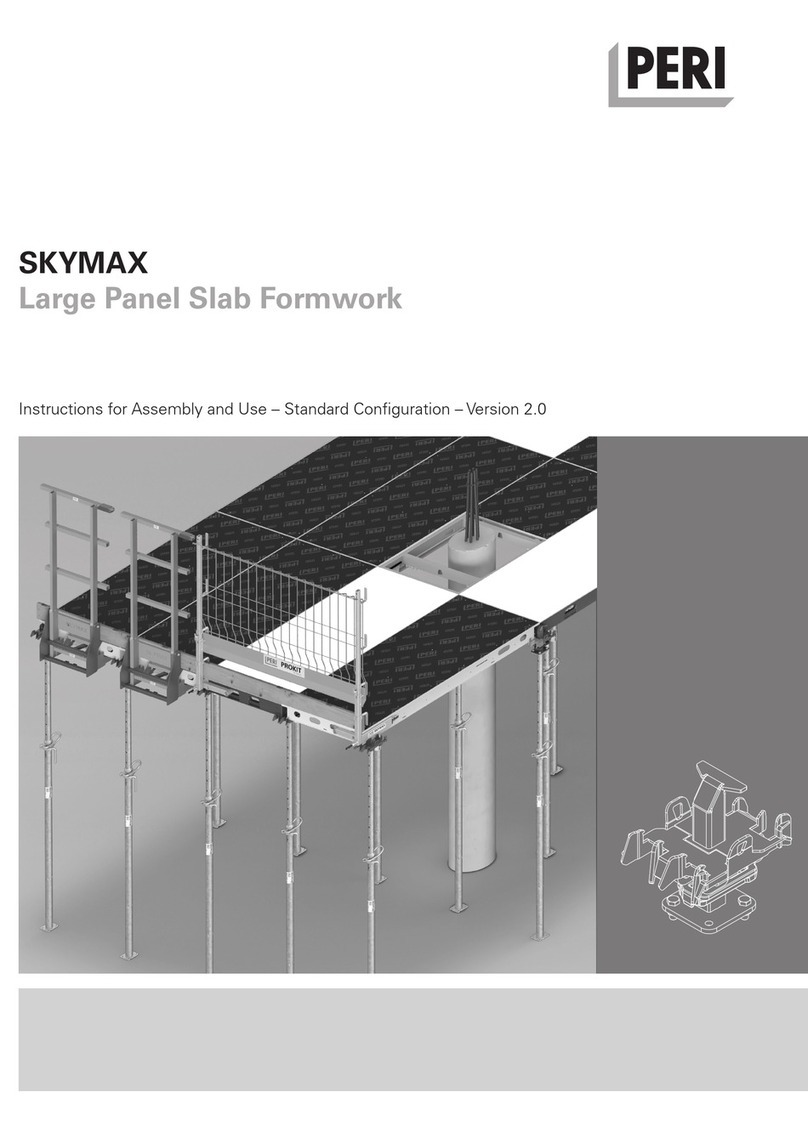

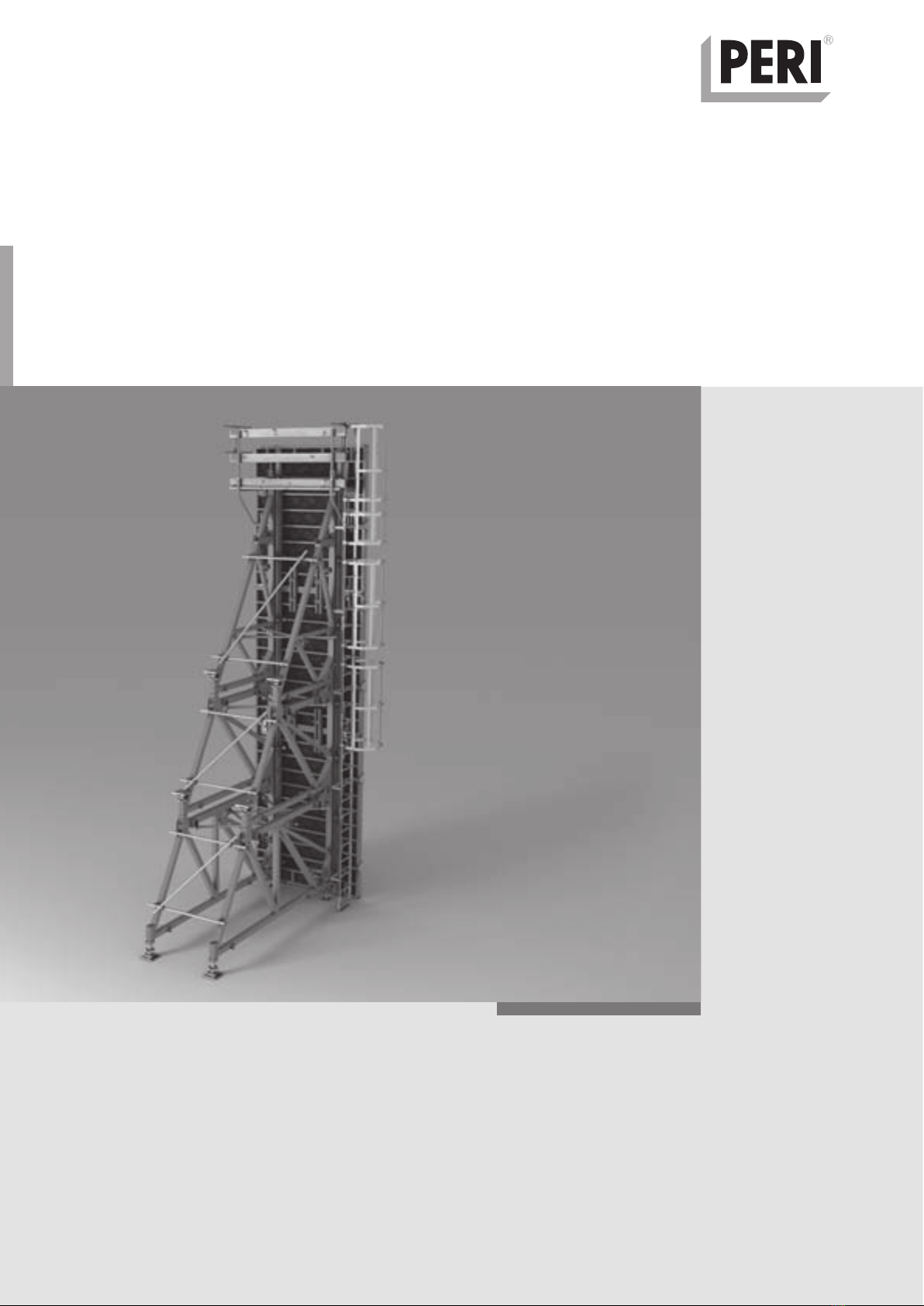

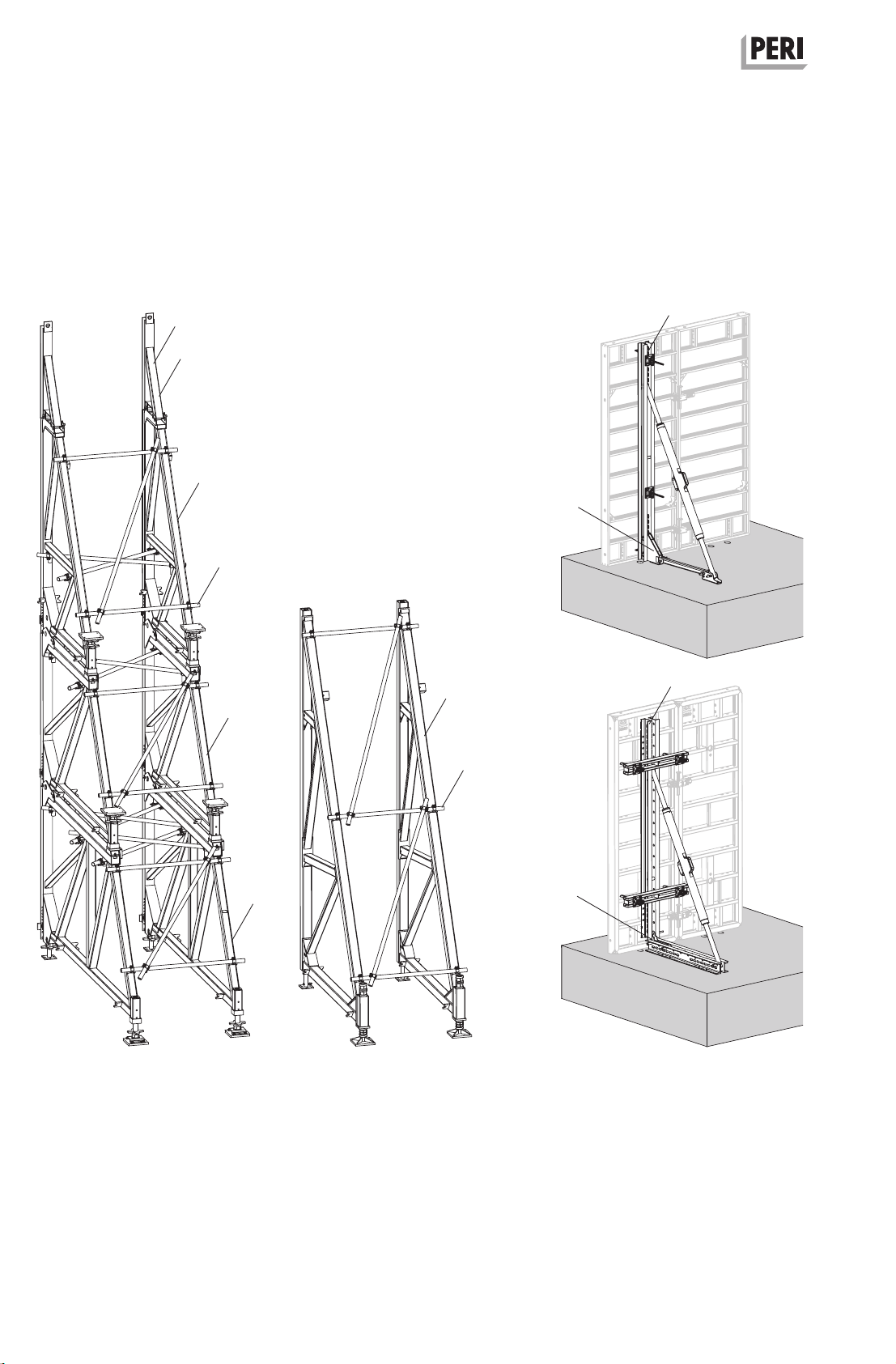

SB Brace Frame for single-sided walls

Instructions for Assembly and Use – Standard Configuration

Safety Instructions

Cross-system

General

The contractor must ensure that the In-

structions for Assembly and Use sup-

plied by PERI are available at all times

and are understood by the site person-

nel.

These Instructions for Assembly and

Use can be used as the basis for creat-

ing a risk assessment. The risk assess-

ment shall be compiled by the contrac-

tor. The Instructions for Assembly and

Use do not replace the risk assessment!

Always take into consideration and com-

ply with the safety instructions and per-

missible loads.

For the application and inspection of

PERI products, the current safety regu-

lations and guidelines must be observed

in the respective countries where they

are being used.

Materials and working areas are to be

inspected on a regular basis especially

before each use and assembly for:

signs of damage,

stability and

functionality.

Damaged components must be ex-

changed immediately on site and may

no longer be used.

Safety components are removed only

when they are no longer required.

Components provided by the contractor

must conform with the characteristics

required in these Instructions for As-

sembly and Use as well as with all valid

construction guidelines and standards.

In particular, the following applies if

nothing else is specified:

timber components: Strength Class

C24 for Solid Wood according to EN

338.

scaffold tubes: galvanised steel tubes

with minimum dimensions of Ø 48.3

x 3.2 mm according to EN 12811-

1:2003 4.2.1.2.

scaffold tube couplings according to

EN 74.

Deviations from the standard configura-

tion are only permitted after a further

risk assessment has been carried out by

the contractor.On the basis of this risk

assessment, determine appropriate

measures for working and operational

safety as well as stability.

Corresponding proof of stability can be

provided by PERI on request if the risk

assessment and resulting measures to

be implemented are available.

Before and after exceptional occurrenc-

es that may have an adverse effect re-

garding the safety of the formwork sys-

tem, the contractor must immediately

create another risk assessment, with

appropriate measures for ensuring

the stability of the formwork system

being carried out based on the re-

sults,

and arrange for an extraordinary in-

spection by a qualified person. The

aim of this inspection is to identify

and rectify any damage in good time

in order to guarantee the safe use of

the formwork system.

Exceptional occurrences can include:

accidents,

longer periods of non-use,

natural events, e.g. heavy rainfall, ic-

ing, heavy snowfall, storms or earth-

quakes.

Assembly, modification and disman-

tling work

Assembly, modification or dismantling

of formwork systems may only be car-

ried out by qualified specialists under

the supervision of an authorized person.

The qualified specialists must have re-

ceived appropriate training for the work

to be carried out with regard to specific

risks and dangers.

On the basis of the risk assessment and

Instructions for Assembly and Use, the

contractor must create installation in-

structions in order to ensure safe as-

sembly, modification and dismantling of

the formwork system.

The contractor must ensure that the

personal protective equipment required

for the assembly, modification or dis-

mantling of the system, e.g.

safety helmet,

safety shoes,

safety gloves,

safety glasses,

is available and used as intended.

If personal protective equipment (PPE)

is required or specified in local regula-

tions, the contractor must determine ap-

propriate load-bearing points on the ba-

sis of the risk assessment.

The personal protective equipment to

be used is determined by the contrac-

tor.

The contractor must

provide safe working areas for site

personnel which are to be reached

through the provision of safe traffic

routes. Areas of risk must be cor-

doned off and clearly marked.

ensure the stability during all stages

of construction, in particular during

assembly, modification and disman-

tling of the formwork.

ensure and prove that all loads are

safely transferred.

Utilization

Every contractor who uses or allows

formwork systems or sections of the

formwork to be used, has the responsi-

bility for ensuring that the equipment is

in good condition.

If the formwork system is used succes-

sively or at the same time by several

contractors, the health and safety coor-

dinator must point out any possible mu-

tual hazards and all work must be then

coordinated.