D Installation on Harness

1Attach the device to the harness by passing a connector through the connection holes. ISC recommends the use of maillions. The maillion used to secure the Main Attachment Point should be closed

using a spanner to ensure that the connector can not be opened accidentally. The connector used in the Secondary Attachment Point is used to mantain the correct vertical orientation of the device

against the chest.

2When the harness is not in use, always close the cam of the device so objects do not become jammed in the device.

E Use

1Rope ascending - To ascend a rope use this unit with another rope clamp (ISC hand ascender) and footloop.

2Short descent of rope - To move down the rope a short distance, slide the device up the rope and simulta neously push the top of the cam in a downward direction. Ensure your ngers do not get

stuck between the rope and the cam. Do not use the cam safety catch to manipulate the cam-this could cause the rope to come out of the device.

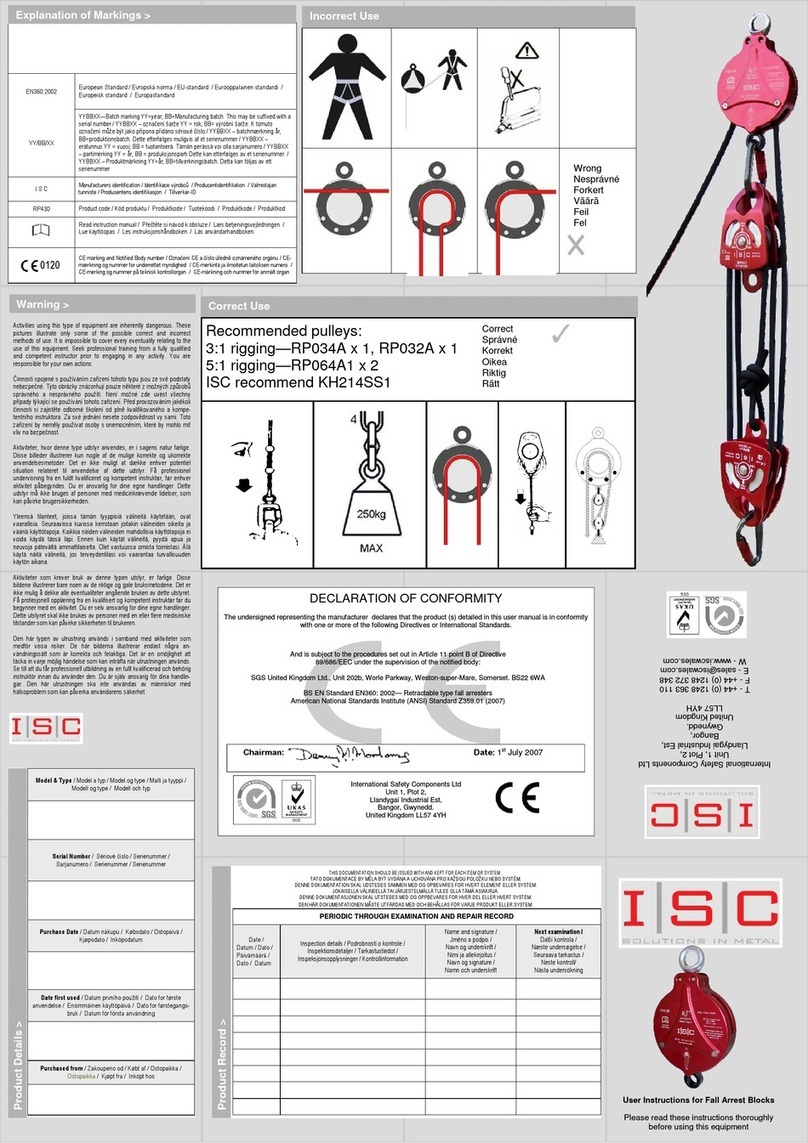

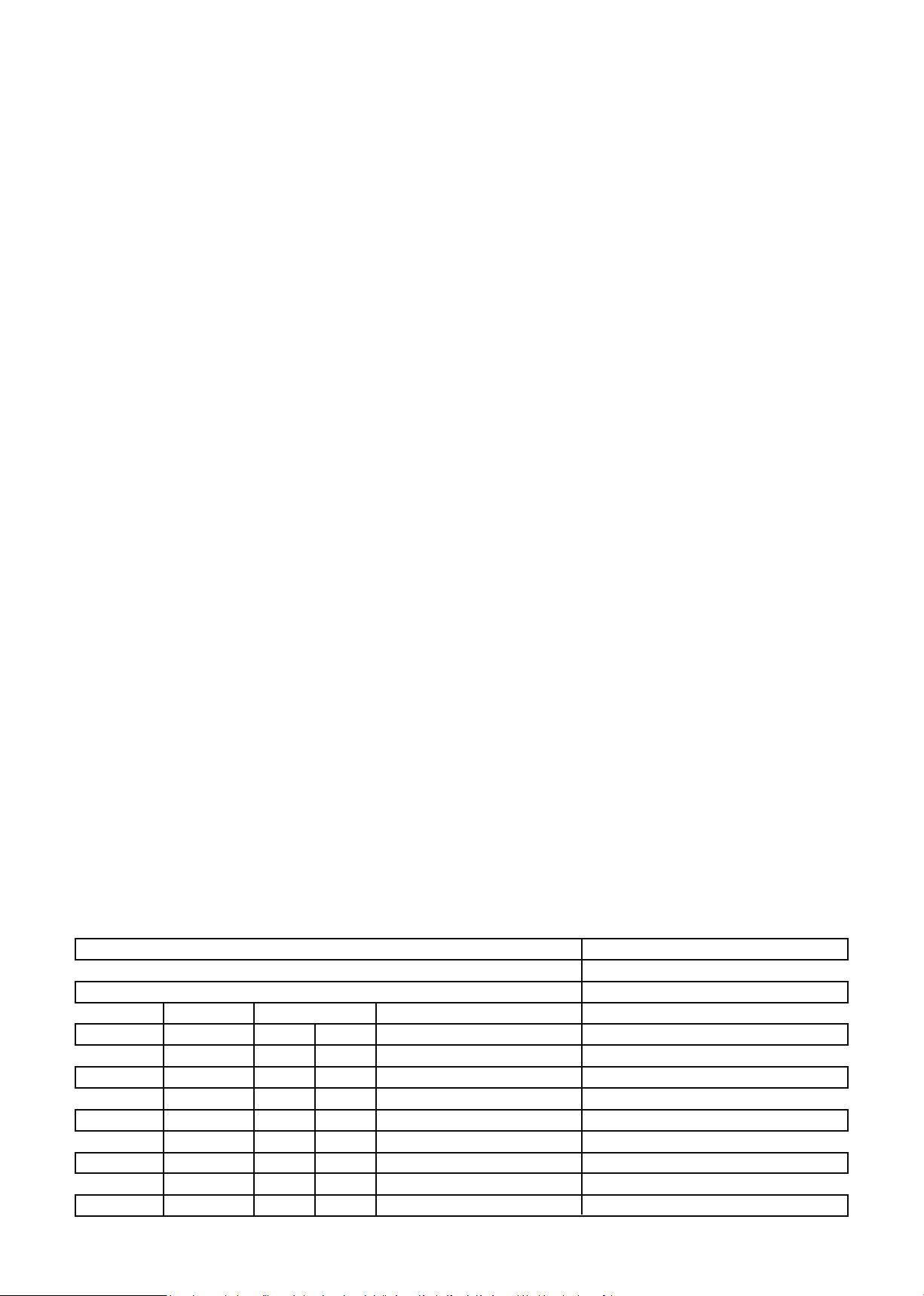

Product Record

1Item 2Serial Number 3Year of Manufacture 4Purchased From 5Purchase Date 6Name of Manufacturer 7Date of First Use 8Inspection Date 9Reason (periodic examination (E)or repair (R))

10 Conform 11 Comments 12 Signature

General

ISC equipment and components for prevention of falls from height meet or exceed recognised European, American or other International standards. A multi-language user instruction manual should

accompany this product. It is the users responsibility to read and understand these instructions before use. If this product is sold outside of the original country of sale, it is the resellers responsibility to

supply this document in the language of re-sale.

WARNING - Activities involving the use of this equipment are inherently dangerous. This equipment should only be used by a competent person or a person specically trained in its use who is

under the supersion of a competent person

Responsibility

It is the user’s responsibility to ensure understanding of the correct safe use of this equipment, to use it only for the purposes for which it is designed, and to practise all proper safety procedures. It is

mandatory that a Risk Assessment be carried out prior to any use and a rescue plan be in place for any work at height. Do not exceed loads either specied by the manufacturer or loads derived from

the specied MBS using a recognised factor of safety. This equipment should not be used by persons with a medical condition(s) that may aect the safety of the user.

Compatibility

Always ensure that all components within a safety system are compatible and allow the system to function safely. Make sure that the connectors used to attach this device to your harness are

compatible with the rope clamp (size, shape, etc.)

Use Inspection

Immediately before, during and after use make visual inspections of the product to ensure that it is in a serviceable condition and is operating correctly. Check the legibility of all markings.

Use Requirements

It is recommended that the viability of any installation should be veried by a suitably qualied person. Extreme care should be taken when using this product near harmful chemicals, mov ing

machinery, electrical hazards and near sharp edges and abrasive surfaces. Wet and icy conditions may cause the rope to become slippery.

Modications, repair

There are no serviceable parts on this unit. Do not under any circumstances mod ify the product as alterations may ren der it ineective.

Product Inspection & Maintenance

In addition to the visual inspections (see Inspection) a thorough examination should be carried out by a competent person in line with applicable legislation and the intensity and environment of use.

ISC recommends a thorough ex amination at least every twelve months. The product should be immediately withdrawn from use and not used again until conrmed in writing by a competent person

that it is safe to do so, should any doubt arise about its condition for safe use or, if it has been used to arrest a fall. Extreme temperatures and the eects of chemicals, rust, cuts and abrasions could

aect the performance and lifespan of the

equipment, to as little as a single use. The potential lifetime of ISC products is up to 10 years for plastic or textile products, and inde nite for metal products. The actual lifetime of a product depends

on a variety of factors such as, the intensity of use, the frequency of use, the environment in which it has been used, the competency of the user, and how well it has been maintained and stored etc.

Defective equipment shall be put beyond use to ensure it is not used as safety equipment.

Storage & Transportation

The product should be stored in a clean, dry environment away from exposure to UV, corrosive or chemical substances or extreme heat sources. Care should be taken to protect the product against

damage during transportation.

Cleaning

The product must be cleaned regularly ( or after every use in a marine environment) with a mild detergent. Afterwards the product should be rinsed in clean water and allowed to dry naturally. Al-

ternatively an air gun can be used to clear debris from device. Moving parts may be oiled regularly with a light oil such as 3-in-1. A small drop may be applied to the axle on the cam and the cam safety

catch pivot.

Manufacturers’ responsibility

The manufacturer or distributor will not be held responsible for any eventual damages, injuries or death resulting from an improper use of this equipment. If there is any doubt about the compatibility

of the products you have chosen please consult the manufacturer

Approvals - Declaration of Conformity This device is manufactured by ISC, Llandygai Industrial Est., Bangor, Gwynedd. LL57 4YH

Certication

Personal Protective Equipment Regulation (EU) 2016/425

Notied Body having carried out the CE type test (Module B):

SATRA Technology Europe Ltd. (2777),

Bracetown Business Park,

Clonee,

Dublin,

D15 YN2P.

Ireland

Notied body responsible for production monitoring and inspection

(Module D):

SGS Fimko Oy (0598)

Takomotie 8

FI-00380 Helsinki

Finland

RP229 Series Issue C. February 2021

1

23

4

6

8 9 10 11

5

7

12

PRODUCT RECORD