HD3600/20/B

3-15

Replacing the Peltier element:

- When the Peltier element has to be replaced, first remove

the rear case assy and Fan assy.

- Unscrew the 2 screws located on the heat sink.

- The heat sink including Peltier element can now be

removed.

- With a small screwdriver the Peltier element can be removed

from the heat sink, some force maybe needed.

- Before placing the new Peltier element, provide heat sink

paste on both side of the Peltier element.

- Place the new Peltier element on the cooler plate on the

same position of the removed Peltier element.

NOTE! It is important to place the Peltier element with

the right side on the COOLER PLATE.

- The cooler plate is the aluminium part fixed in the

appliance, where the KEG will be cooled on.

- The heat sink is the aluminium part where the fan is

assembled on.

- In other words, the cooling side of the Peltier has to point

to the COOLER PLATE and the warm side has to point to

the HEAT SINK.

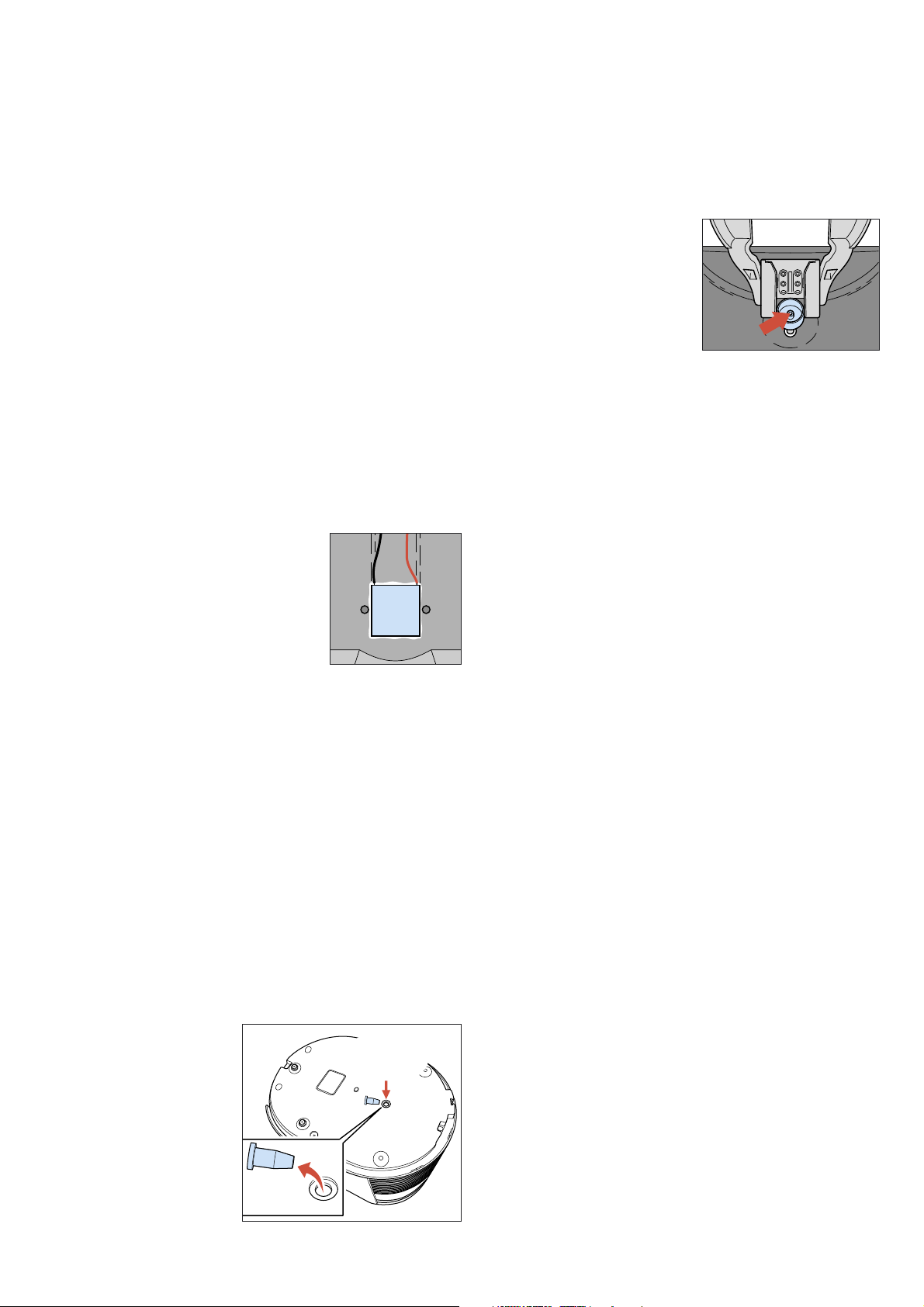

- Details to check are:

• Soldered joints must be pointing

to the cooling plate.

(when Peltier is placed on the

cooler plate the soldered joints

are not visible, seen from the

backside)

• Colours of wires must be equal

positioned see, picture for detail.

- Be careful and make sure the Peltier element is well placed.

- Now the heat sink can be placed on the peltier element.

- Tighten the screws alternate, to prevent damaging the

Peltier element for mounting lop-sided.

- Maximum force that maybe applied to tighten the screws

are: 0.6 Nm.

Procedure for checking cool down

performance Peltier element.

To ensure the Cool performance of the Peltier element is

according specification the below test procedure have to be

carried out.

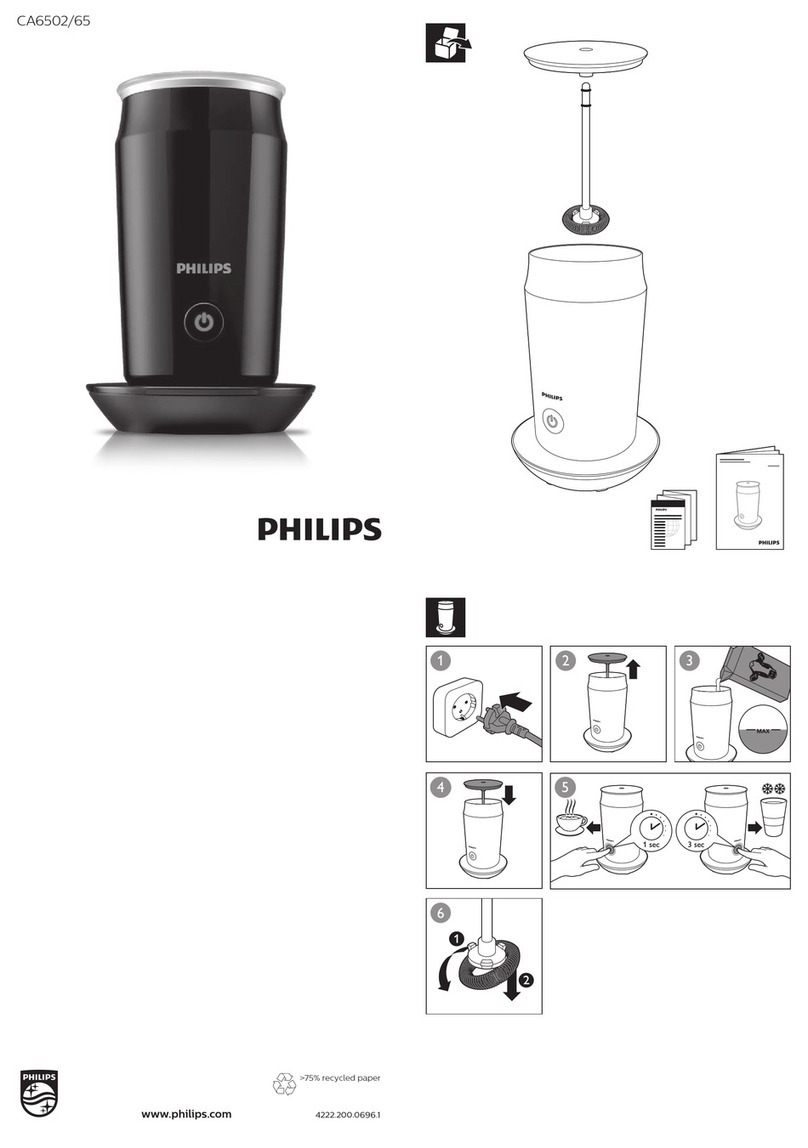

- Preparations:

1. Switch the appliance off and let it stabilize until it

reached room temperature.

2. Remove under the base in the middle the rubber Cap.

3. The chiller plate

becomes visible.

DISASSEMBLY- AND RE-ASSEMBLY ADVISE

- Performing the temperature measurement, when the unit

has reached the room/environment temperature.

1. Place a contact temperature probe against the chiller

plate where the rubber cap was removed.

2. Block the air inlet

coupling at the Keg

side, see picture 6 for

location.

3. Plug the appliance in the wall socket and bridge over

the Keg present switch mechanically or electrically so

the appliance will start.

4. When the appliance has started the pump will run

shortly (in case the air inlet has been blocked properly)

5. Readout the temperature meter and note it down.

6. Keep the appliance switched on for 2 minutes, readout

the temperature again.

7. If the temperature has decreased more then 6 °C,

between the two measurements the cooling works fine,

if not please check again or replace Peltier or Fan assy.

- Final:

When the appliance is checked and OK, place the rubber

Cap back under the base.

Replacing pressure sensor PCB:

- To replace the pressure sensor PCB assy, situated on the

pump, unscrew the 2 screws completely.

- Disconnect the connector, gently turn the PCB assy left and

right and at the same time pull the unit up.

Sometimes also the side cap must be unscrewed a little to be

able to remove the pressure sensor.

- Place the new PCB assy and check if the small rubber ring

on the sensor tube is on its place.

Replacing the pump unit:

- Start with disconnecting the air pressure hose and electrical

connections.

- Unscrew the 3 screws from the plastic bracket were the

pump unit is hanging on.

- To re-assembly carry out steps backwards.

NOTE! To prevent leakage at the connection side of the

hose, cut a small piece off the end of the hose.

Picture 4.

rubber

Cap

contact

temperature

probe

Picture 5.

Picture 6.