Picote Soluons Oy Ltd 5www.picoteinstute.com

TRANSPORT

The Baery Mini Cleaner or Baery Mini Cleaner +C should be transported in a car or other vehicle and laid down and

secured with ratchet straps to prevent any sudden movements or accidents caused by hard braking or accident.

Never transport the machine with a tool aached to the sha. Always retract the camera back to its housing for

transport. If using a pick-up or trailer to transport a Baery Mini Cleaner or Baery Mini Cleaner +C always suitably

cover the unit to protect it from the elements.

STORAGE

Baery Mini Cleaners should be stored indoors to protect them from rain and sunlight, somewhere with a constant

ambient temperature. The best way to store the Miller is using the same box that it was shipped in.

If the Baery Mini Cleaner or Baery Mini Cleaner +C has been stored in an environment colder than +10 oC or +50 oF,

the machine should be stood at room temperature for 24 hours before use.

If the Baery Mini Cleaner or Baery Mini Cleaner +C has been stored for long periods of me (over 2-3 months), it

should be checked and tested according to the maintenance programme before use.

Charge the machine baery to around 80% capacity before storing for long periods. NEVER leave the baery unit un-

aended while it is charging.

Charge the DVR baery fully before storing for long periods. NEVER leave the DVR unit unaended while it is charging.

DISPOSAL

Baery Mini Cleaner motor, control box, baery charger, electric wires, axle package including slip ring, camera

monitoring box, power supply and camera head can be disposed of in Europe at Waste Electrical and Electronic

Equipment (WEEE) collecon points.

The Miller frame, reel, exible sha, camera cable reel and name plate can be recycled in metal waste collecon points.

Outer casing of the sha and the camera plasc supports can be disposed of as plasc waste.

Always follow local waste handling rules and regulaons.

Recycle Li-ion baeries according to local regulaons. Do not dispose of in re! Do not puncture!

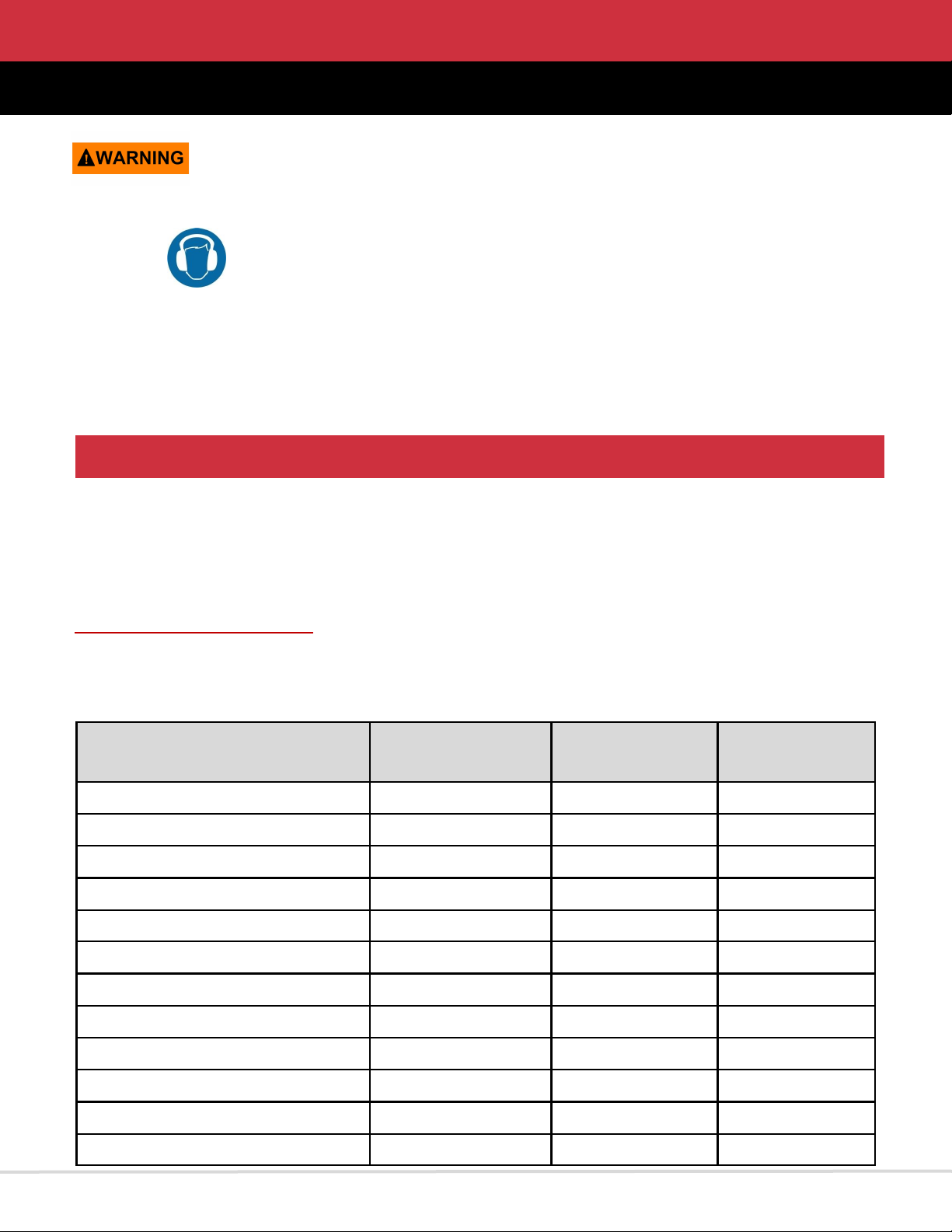

ENVIRONMENTAL

Operaonal Ambient Temperature Range: -10 oC to +50 oC (+14 oF to +122 oF) frost and condensaon free

Storage Ambient Temperature Range: -20 oC to +60 oC (-4 oF to +140 oF) frost and condensaon free

Maximum Altude: 2000m or 6500 . Derate above 1000m or 3280: 1% / 100m or

328

Maximum Humidity: 95% non-condensing

Camera Maximum Humidity: 90% non-condensing

This secon contains important safety informaon. Failure to comply could result in serious injury or death

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

ENVIRONMENT, TRANSPORT, STORAGE & DISPOSAL