1. Introduction

KOP 3 battery chargers are modern fully automatic devices suitable not only for2 00

charging but also for maintaining and monitoring the batteries. The charger stores

data about charging times and Ah charged. This data may be accessed for further

analysis. The device is protected against reverse polarity and short circuit, has

adjustable time limitations for every charging phase, battery temperature

monitoring and compensation and current reduction at elevated ambient

temperatures.

Your battery charger was programmed for a specific battery type .by your dealer

Make sure the charging profile suits your battery type. To change the charging

profile for a specific battery type, parameters can only be programmed with a PC

software package and a programming interface. The programming parameters

allow the charger's profile to suit the battery type. Up to five charging phases can be

programmed with separate values for charging voltages, currents, charging times,

temperature compensation and other control functions. Please contact your dealer

for further information.

When programming the charging profile always follow the battery manufacturer's

recommendations.

Please read the operating and safety instruction carefully

before using or installing the KOP2300 battery charger!

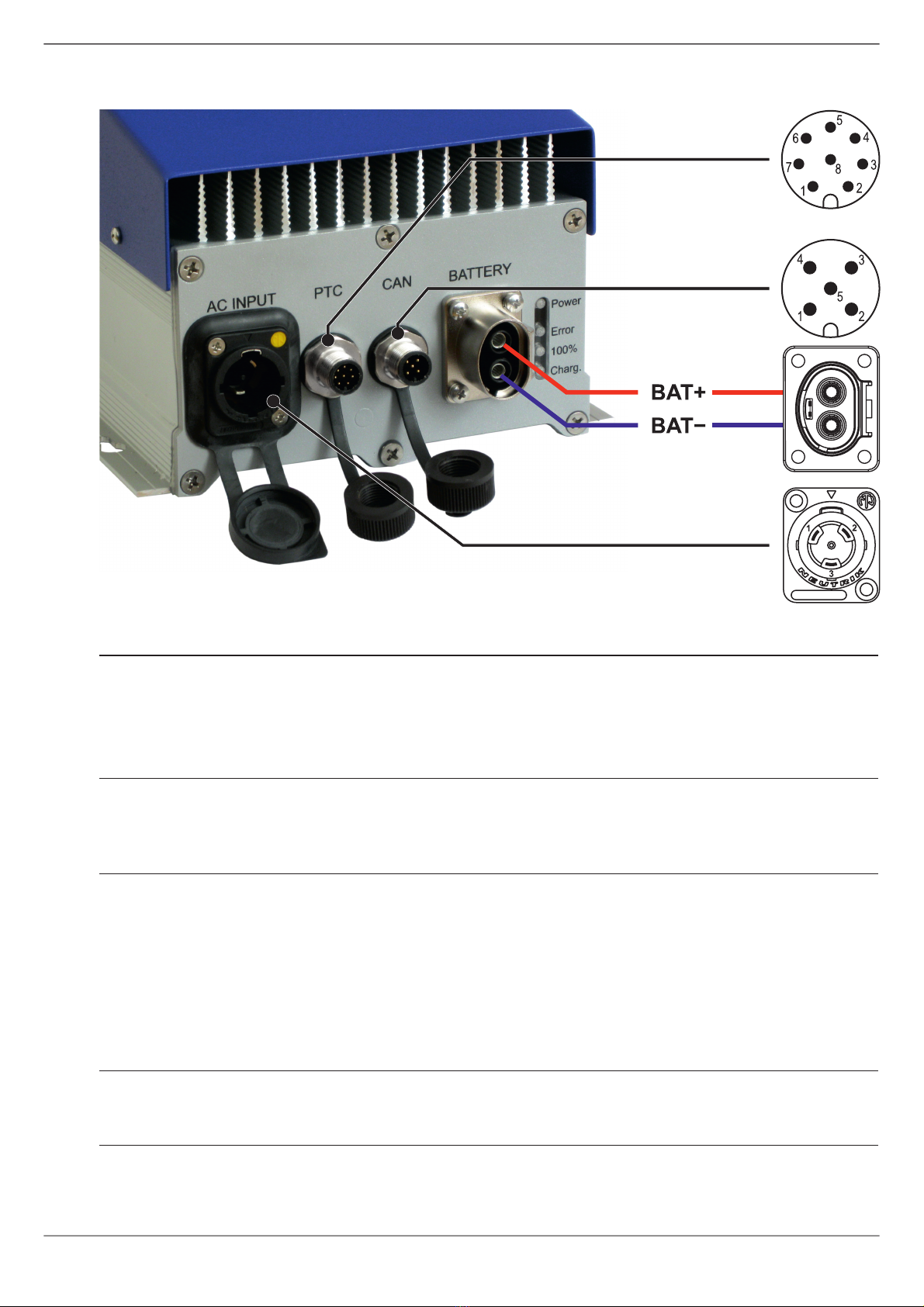

2. Start of the charging process

Establish a safe connection between the battery and the charger first. Then plug the

mains connector. When removing the connection, remove the mains plug from the

mains first, before disconnecting the battery.

The charger type is shown first after the charger has been connected to the mains

and then the measured values as the battery voltage – see the following page.

The charging time depends on battery size and state of charge. If the battery was

only slightly loaded, then the charging process will complete faster. At high ambient

temperatures or when exposed to strong sunlight, the charging current is reduced

and the charging time increased accordingly.

The charger can remain connected to the battery permanently. The current

consumption is less than 0. mA.from the battery 2

10

ENGLISH