Contents

Operating Manual PNOZ m EF 4DI4DOR

1002702-EN-08 | 3

1 Introduction ............................................................................................................................5

1.1 Validity of documentation.......................................................................................................... 5

1.2 Using the documentation .......................................................................................................... 5

1.3 Definition of symbols................................................................................................................. 5

2 Overview .................................................................................................................................7

2.1 Scope of supply ........................................................................................................................ 7

2.2 Unit features ............................................................................................................................. 7

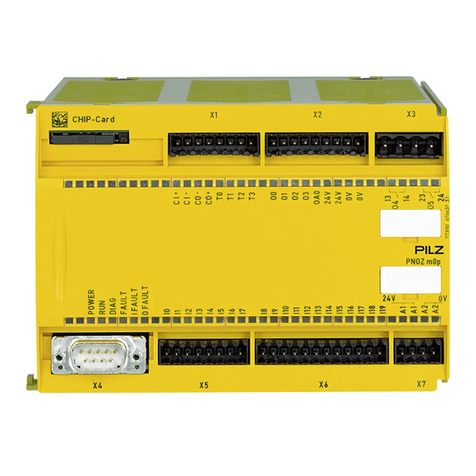

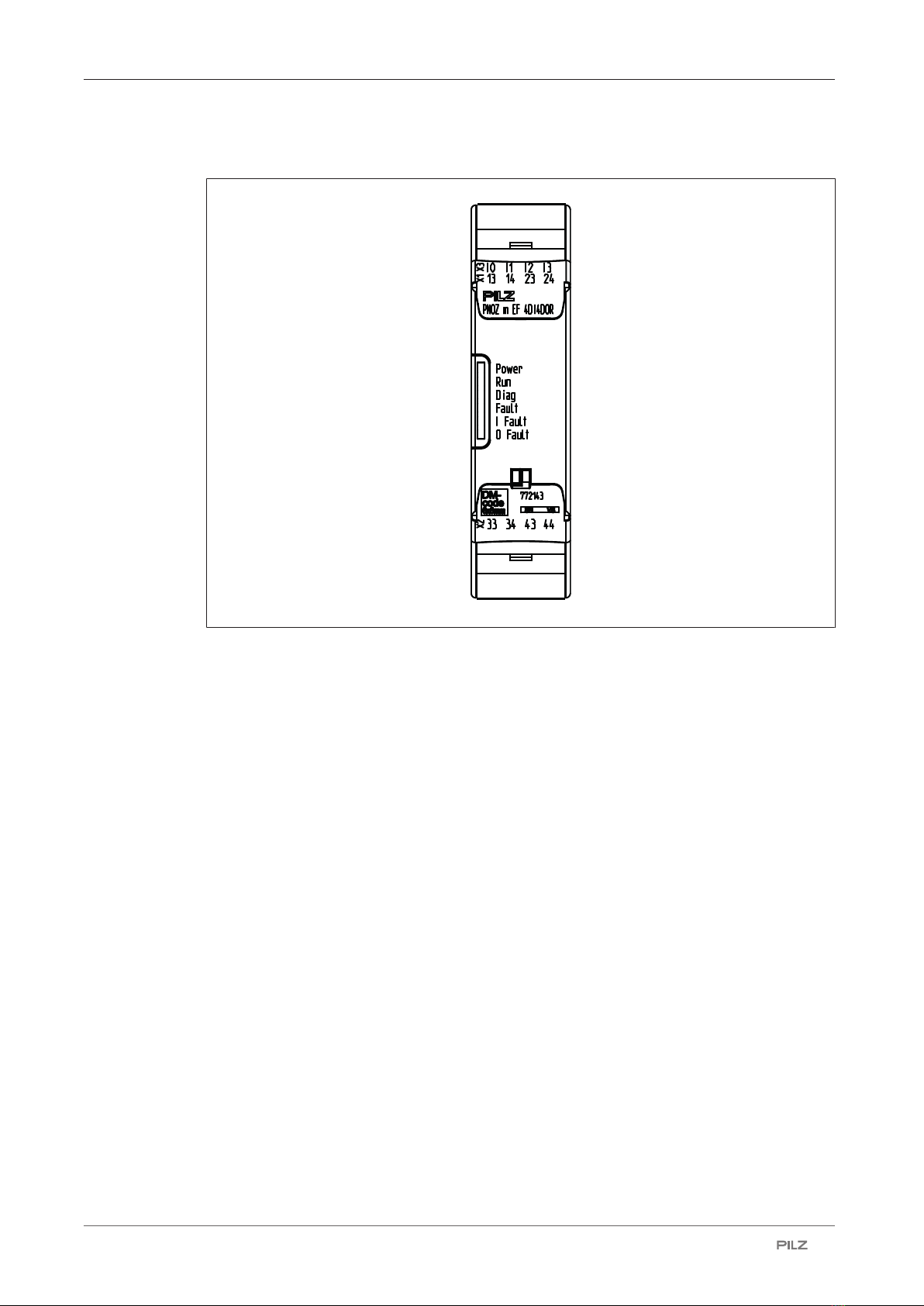

2.3 Front view ................................................................................................................................. 8

3 Safety ...................................................................................................................................... 9

3.1 Intended use ............................................................................................................................. 9

3.2 System requirements................................................................................................................ 9

3.3 Safety regulations ..................................................................................................................... 10

3.3.1 Safety assessment ................................................................................................................... 10

3.3.2 Use of qualified personnel ........................................................................................................ 10

3.3.3 Warranty and liability ................................................................................................................ 10

3.3.4 Disposal .................................................................................................................................... 10

3.3.5 For your safety.......................................................................................................................... 10

4 Function description ............................................................................................................. 12

4.1 Integrated protection mechanisms............................................................................................ 12

4.2 Functions .................................................................................................................................. 12

4.3 System reaction time ................................................................................................................ 12

4.4 Block diagram ........................................................................................................................... 12

5 Installation ..............................................................................................................................13

5.1 General installation guidelines.................................................................................................. 13

5.2 Dimensions in mm .................................................................................................................... 13

5.3 Connecting the base unit and expansion modules ................................................................... 14

6 Commissioning ......................................................................................................................15

6.1 General wiring guidelines ......................................................................................................... 15

6.2 Connection................................................................................................................................ 15

6.3 Download modified project to the PNOZmulti system .............................................................. 16

7 Operation ................................................................................................................................17

7.1 LED indicators .......................................................................................................................... 17

7.2 Function test of the relay outputs.............................................................................................. 18

8 Technical details ....................................................................................................................19

8.1 Safety characteristic data ......................................................................................................... 22

8.2 Classification according to ZVEI, CB24I ................................................................................... 23

9 Supplementary data ..............................................................................................................24

9.1 Service life graph for the relay contacts.................................................................................... 24

9.2 Permitted ambient temperature Tamb dependent on the total current Isum ............................ 26