Pilz PSSu E S 2DOR 10 User manual

Other Pilz Industrial Equipment manuals

Pilz

Pilz PSEN sl-0.5p 1.1 User manual

Pilz

Pilz PSSu E F 2DOR 8 User manual

Pilz

Pilz PSEN op2B/1 Series User manual

Pilz

Pilz PNOZ Owner's manual

Pilz

Pilz PSENop 3.3 User manual

Pilz

Pilz PSEN sc M 3.0 08-12 User manual

Pilz

Pilz PITreader User manual

Pilz

Pilz PSEN cs5.1n User manual

Pilz

Pilz PSS 4000 User manual

Pilz

Pilz PITestop User manual

Pilz

Pilz PSEN 2.1a-20 User manual

Pilz

Pilz PSEN sl-1.0p 2.2 User manual

Pilz

Pilz PIT si3.1 User manual

Pilz

Pilz PNOZ mc4p User manual

Pilz

Pilz PSSu H F PN User manual

Pilz

Pilz PNOZ mi2p User manual

Pilz

Pilz PSEN b1 User manual

Pilz

Pilz PSSu E S PD-D User manual

Pilz

Pilz PSEN op2H-SL Series User manual

Pilz

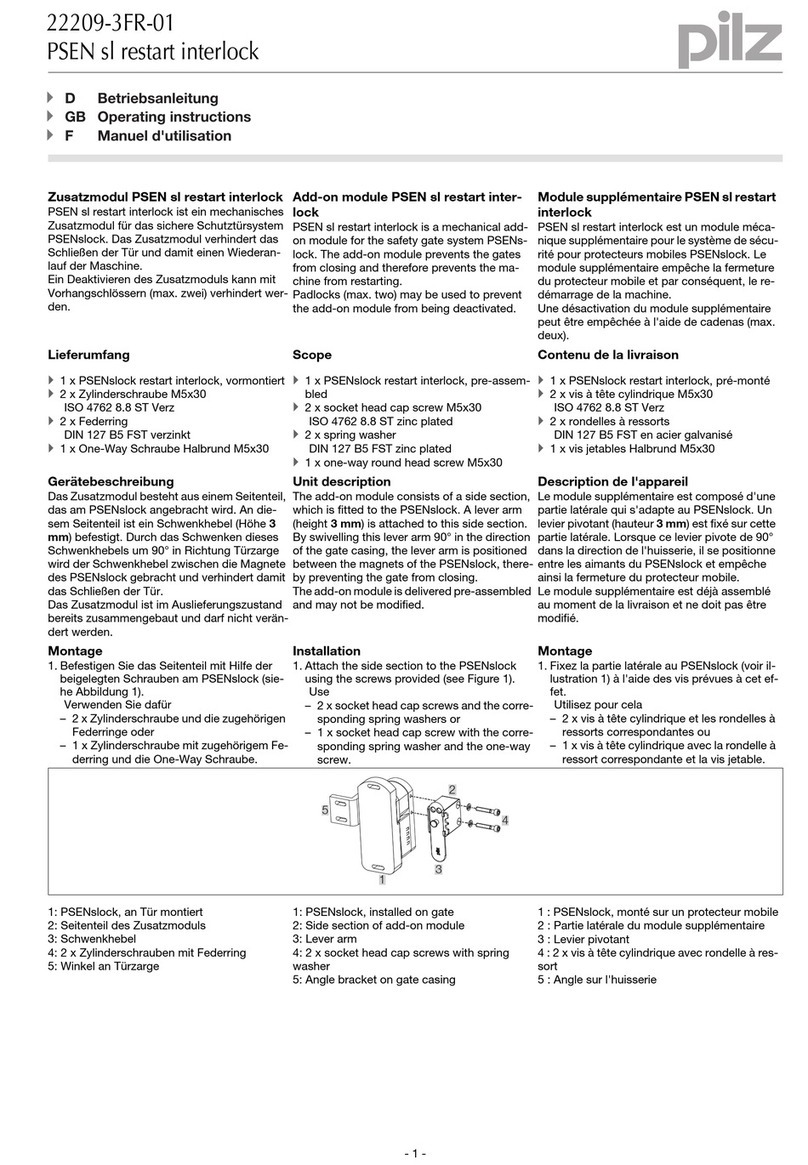

Pilz 22209-3FR-01 User manual