Contents

Operating Manual PSSu H F PN

22071-EN-09 | 3

1 Introduction ............................................................................................................................4

1.1 Validity of documentation.......................................................................................................... 4

1.1.1 Retaining the documentation .................................................................................................... 4

1.2 Definition of symbols................................................................................................................. 4

2 Overview .................................................................................................................................6

2.1 Module features ........................................................................................................................ 6

2.2 Front view ................................................................................................................................. 7

3 Safety ...................................................................................................................................... 8

3.1 Intended use ............................................................................................................................. 8

3.2 Safety regulations ..................................................................................................................... 9

3.2.1 Use of qualified personnel ........................................................................................................ 9

3.2.2 Warranty and liability ................................................................................................................ 9

3.2.3 Disposal .................................................................................................................................... 9

4 Function description ............................................................................................................. 10

4.1 Block diagram ........................................................................................................................... 10

4.2 Supply voltage .......................................................................................................................... 10

4.3 Integrated protection mechanisms............................................................................................ 10

4.4 Projects..................................................................................................................................... 10

4.5 PROFINET................................................................................................................................ 11

4.5.1 Connection to PROFINET ........................................................................................................ 11

4.5.2 DIP switch for setting the F address ......................................................................................... 12

5 Installation ..............................................................................................................................13

5.1 General installation guidelines.................................................................................................. 13

5.2 Dimensions ............................................................................................................................... 13

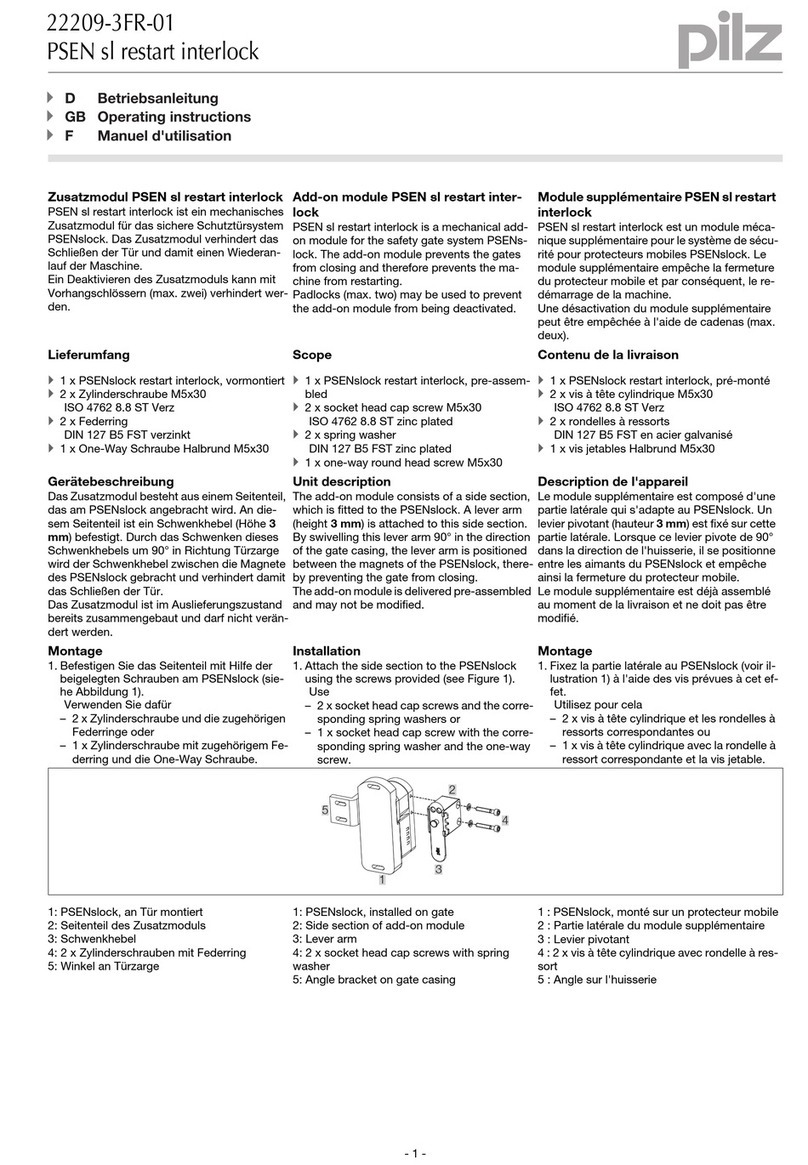

5.3 Installing the head module........................................................................................................ 14

6 Interfaces ................................................................................................................................15

6.1 Interface configuration .............................................................................................................. 15

6.1.1 Connection to PROFINET ....................................................................................................... 15

7 Operation ................................................................................................................................16

7.1 Display elements ...................................................................................................................... 16

8 Technical Details ...................................................................................................................19

8.1 Safety characteristic data ......................................................................................................... 21

9 Order reference ......................................................................................................................22

10 EC declaration of conformity ................................................................................................ 23

11 UKCA-Declaration of Conformity ......................................................................................... 24