Contents

Operating Manual PNOZ e3.1p

21240-EN-09 | 3

Introduction ............................................................................................................................5

Validity of documentation.......................................................................................................... 5

Using the documentation .......................................................................................................... 5

Definition of symbols................................................................................................................. 5

Safety ...................................................................................................................................... 6

Intended use ............................................................................................................................. 6

Safety regulations ..................................................................................................................... 7

Safety assessment ................................................................................................................... 7

Use of qualified personnel ........................................................................................................ 7

Warranty and liability ................................................................................................................ 7

Disposal .................................................................................................................................... 7

Unit features ...........................................................................................................................8

Safety features ....................................................................................................................... 8

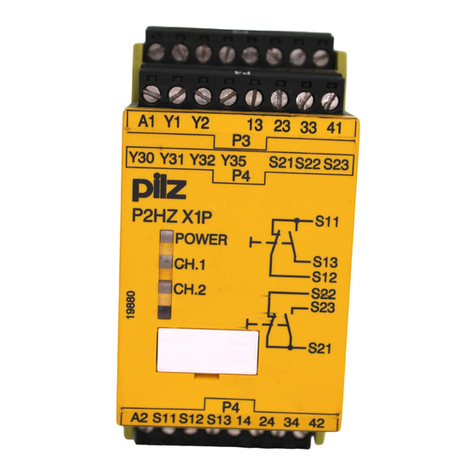

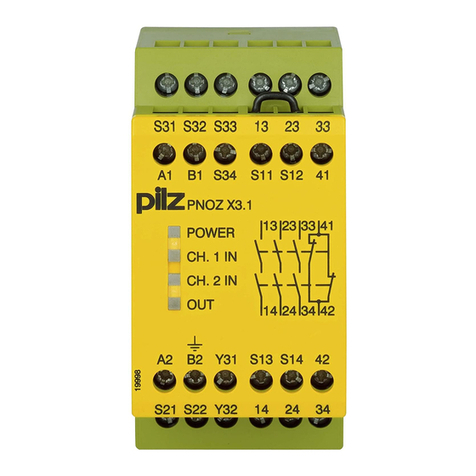

Block diagram/terminal configuration ................................................................................. 8

Function description ............................................................................................................. 9

Operating modes ...................................................................................................................... 9

Installation ..............................................................................................................................10

Wiring ......................................................................................................................................10

Preparing for operation ......................................................................................................... 11

Supply voltage .......................................................................................................................... 11

Input circuit ............................................................................................................................... 11

Start circuit................................................................................................................................ 12

Feedback loop .......................................................................................................................... 12

Logic connection between several units ............................................................................. 13

Logic input S35 and S36........................................................................................................... 14

Examples .................................................................................................................................. 15

Operation ................................................................................................................................19

Status indicators ....................................................................................................................... 19

Faults – Interference .............................................................................................................. 20

Dimensions in mm .................................................................................................................25

Technical details ....................................................................................................................25

Safety characteristic data ......................................................................................................... 29