PNOZ c2

Operating Manual PNOZ c2

22212-EN-04 8

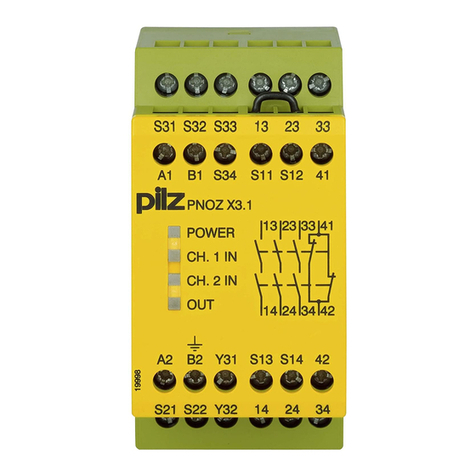

Function description

When the supply voltage is supplied, the "POWER" LED illuminates. The unit is ready for

operation when the start circuit is closed or a start contact in the start circuit is opened and

then closed again.

}High signal at the input circuit (e.g. light guard not interrupted): The safety contacts are

closed and the auxiliary contact is enabled.

}Low signal at the input circuit (e.g. light guard interrupted): The safety contacts are

open and the auxiliary contact is disabled.

}Dual-channel operation without detection of shorts across contacts: Redundant input

circuit, detects earth faults in the start and input circuit .

}Automatic start: Unit is active as soon as a high signal is present at the input circuit.

}Monitored start: Unit is active when there is a high signal at the input circuit is closed

and then the start circuit is closed.

}Increase in the number of available contacts by connecting contact expander modules

or external contactors/relays.

Installation

}The unit should be installed in a control cabinet with a protection type of at least IP54.

}Use the notch on the rear of the unit to attach it to a DIN rail.

}Ensure the unit is mounted securely on a vertical DIN rail (35 mm) by using a fixing ele-

ment (e.g. retaining bracket or an end angle).

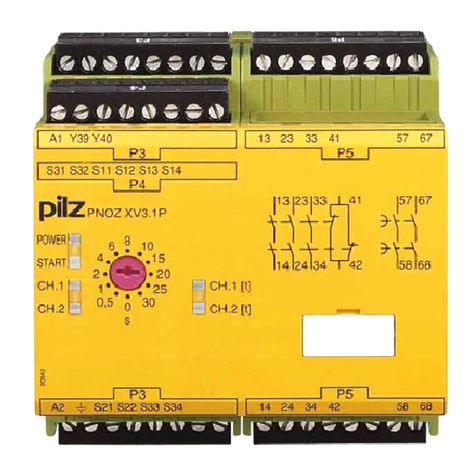

Wiring

Please note:

}Information given in the "Technical details" must be followed.

}Outputs 13-14 and 23-24 are safety contacts, the semiconductor output Y32 is an auxil-

iary output (e.g. for display).

}Semiconductor output Y32 should not be used for safety circuits!

}To prevent contact welding, a fuse should be connected before the output contacts (see

Technical details).

}Use copper wire that can withstand 60/75°C.

}Do not connect capacitive load.

}Do not switch low currents using contacts that have been used previously with high cur-

rents.

}The power supply must comply with the regulations for extra low voltages with protect-

ive electrical separation (SELV, PELV) in accordance with VDE 0100, Part 410.

}Ensure the wiring and EMC requirements of IEC 60204-1 are met.