Pioneer PL-560 User manual

Other Pioneer Turntable manuals

Pioneer

Pioneer PL-Z93 User manual

Pioneer

Pioneer PL-88F User manual

Pioneer

Pioneer DEH-P6500 User manual

Pioneer

Pioneer PL-41A User manual

Pioneer

Pioneer PL-550 User manual

Pioneer

Pioneer PL-225 User manual

Pioneer

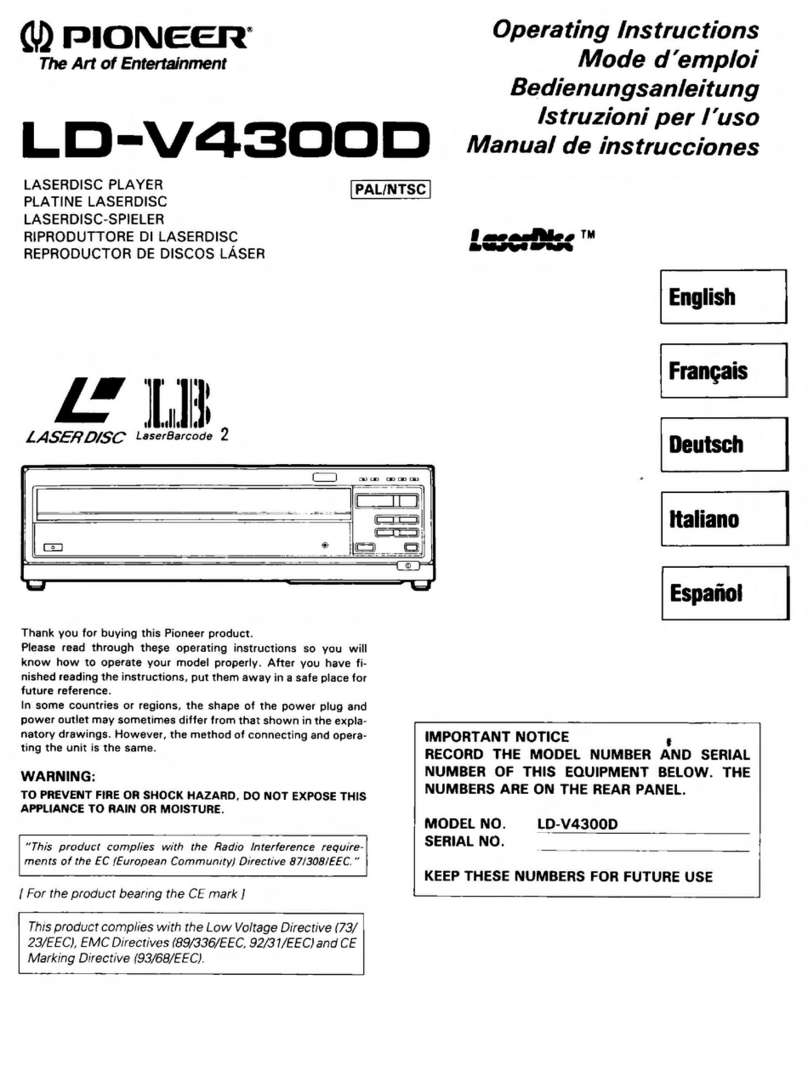

Pioneer LD-V4300D User manual

Pioneer

Pioneer PL-530 User manual

Pioneer

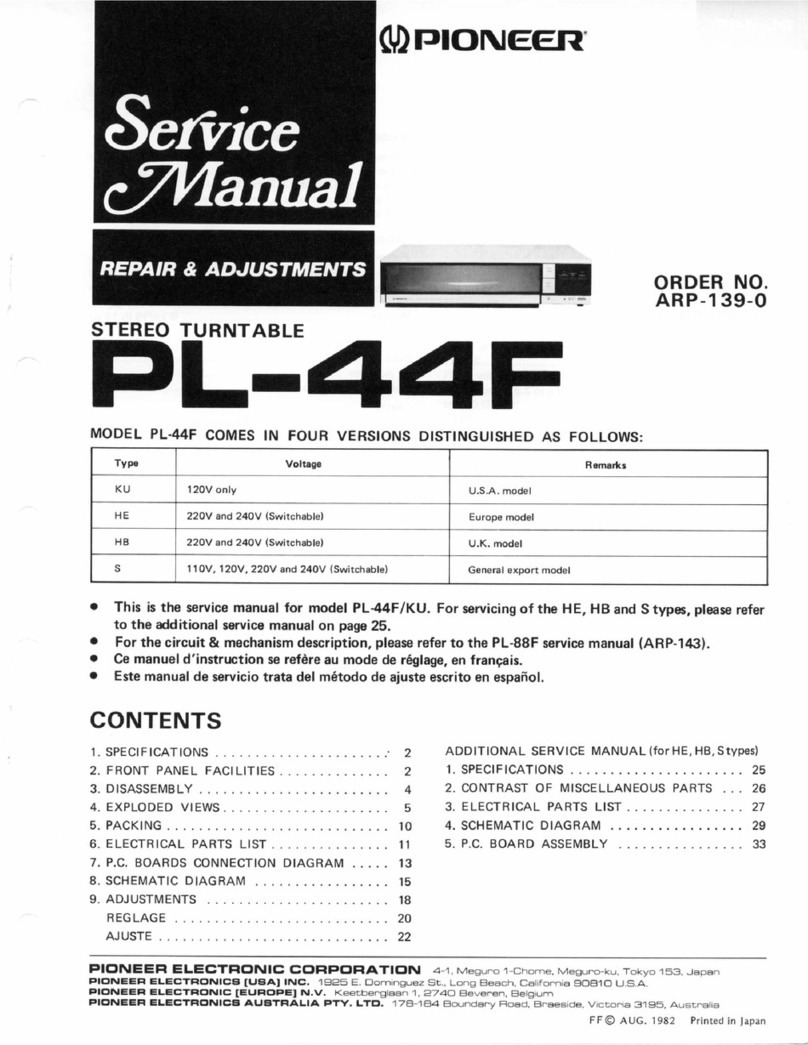

Pioneer PL-44F User manual

Pioneer

Pioneer PL-30-K User manual

Pioneer

Pioneer PL-51 User manual

Pioneer

Pioneer PLX-1000 User manual

Pioneer

Pioneer DEH-2790MP User manual

Pioneer

Pioneer Super Tuner III D DEH-P4800MP User manual

Pioneer

Pioneer LD-V4300D User manual

Pioneer

Pioneer PL-600 User manual

Pioneer

Pioneer PL-500 User manual

Pioneer

Pioneer PL-3000/HB User manual

Pioneer

Pioneer PL-12D User manual

Pioneer

Pioneer PL-450 User manual