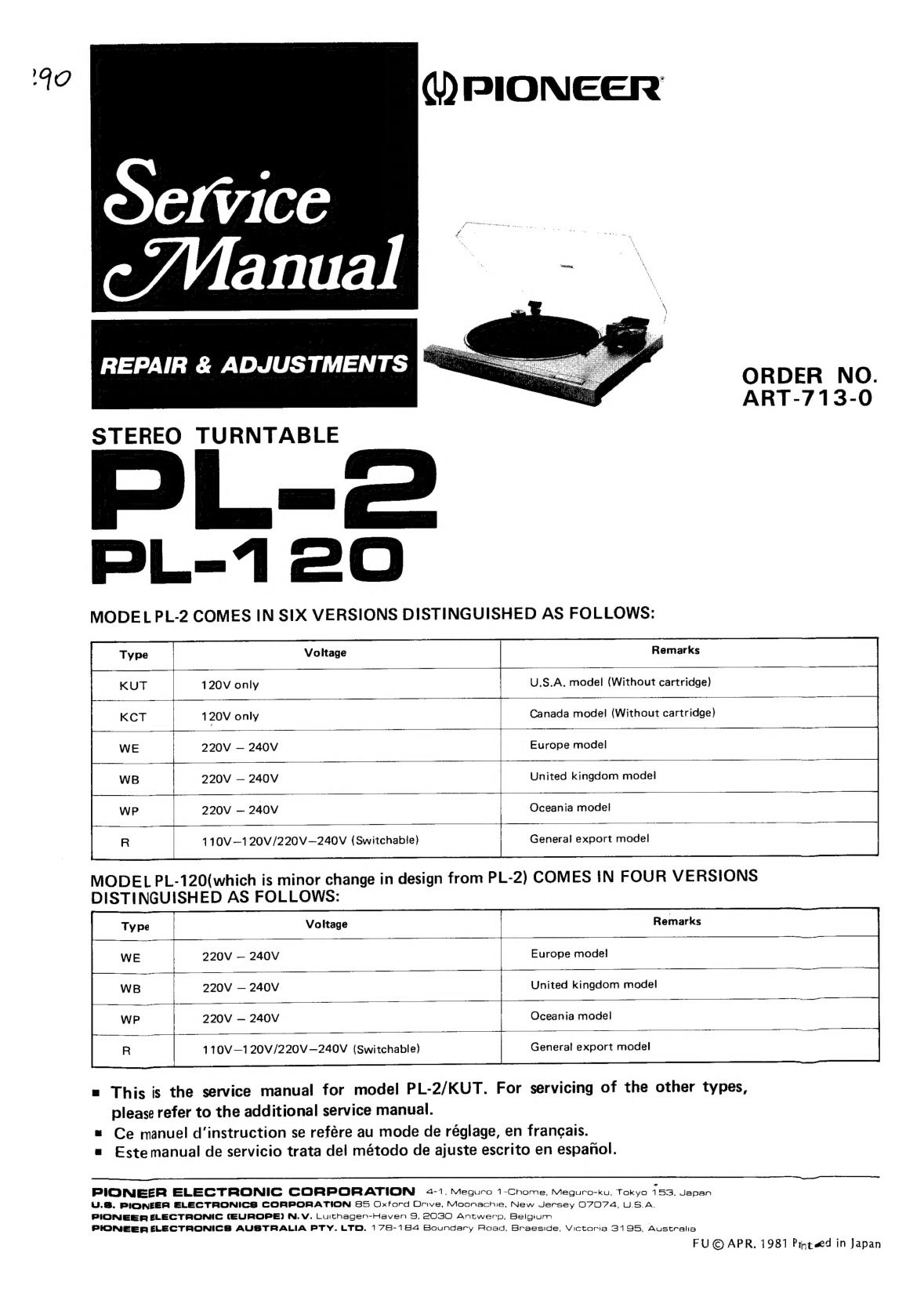

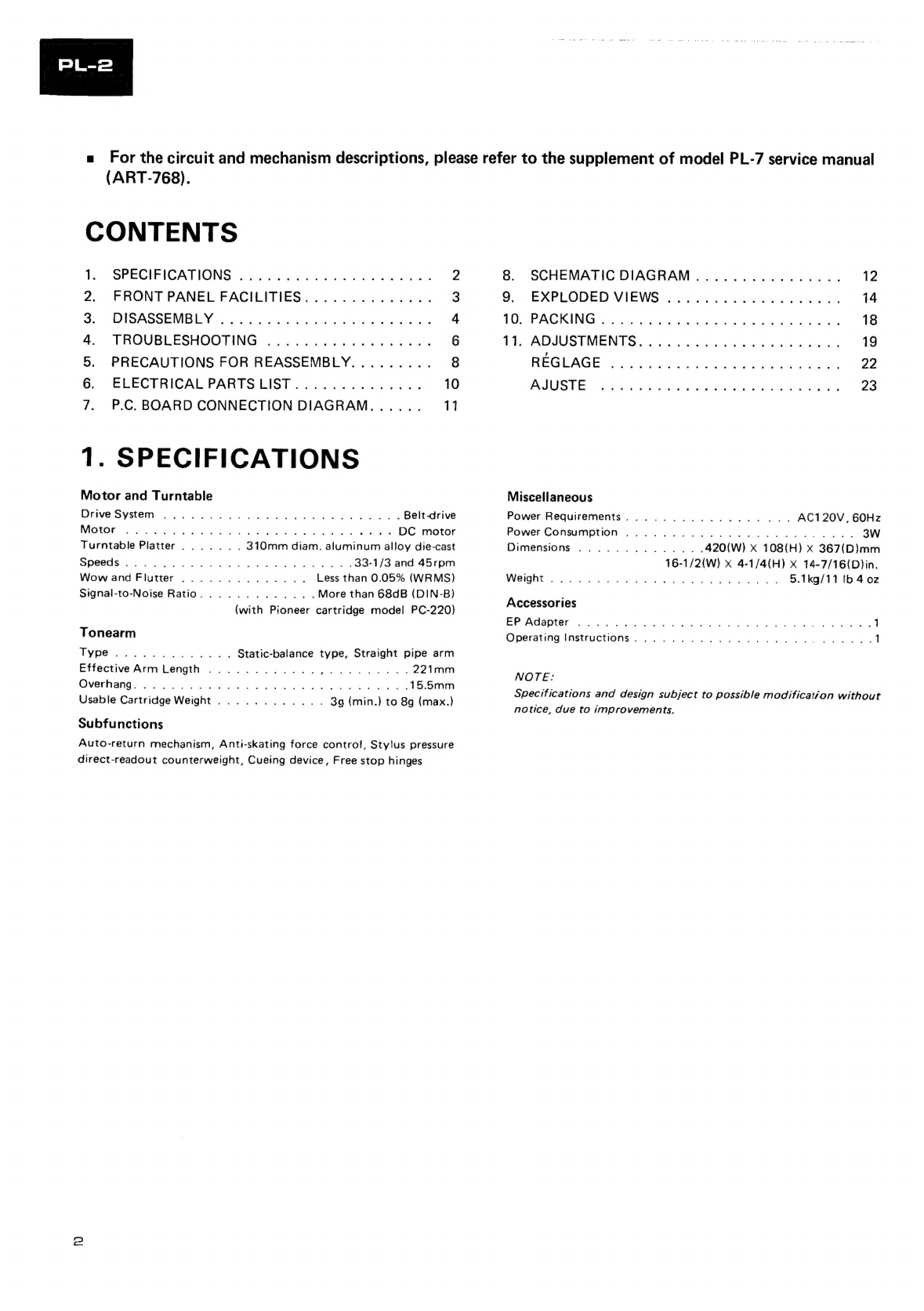

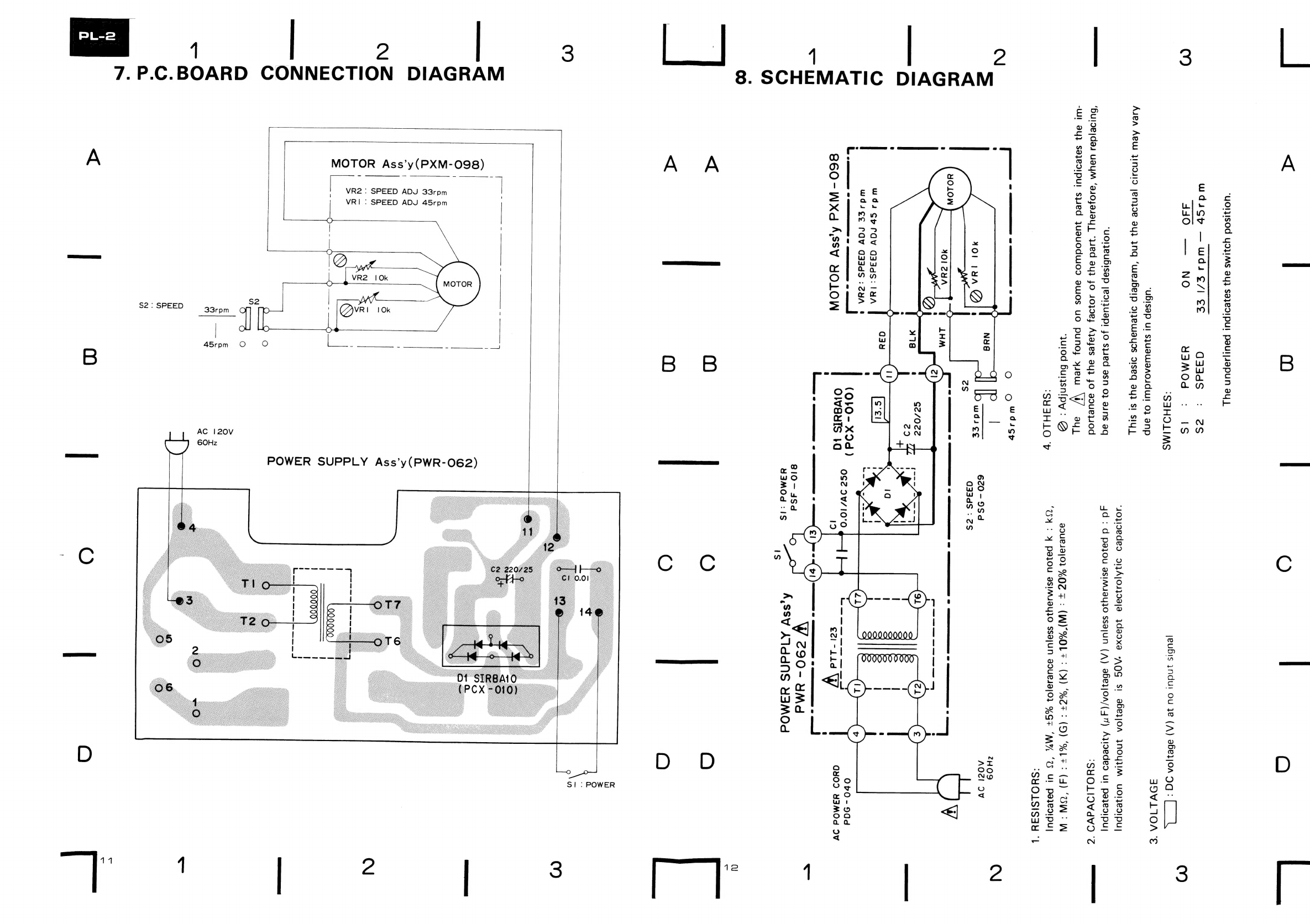

Pioneer PL-2 User manual

Other Pioneer Turntable manuals

Pioneer

Pioneer PL-3000/HB User manual

Pioneer

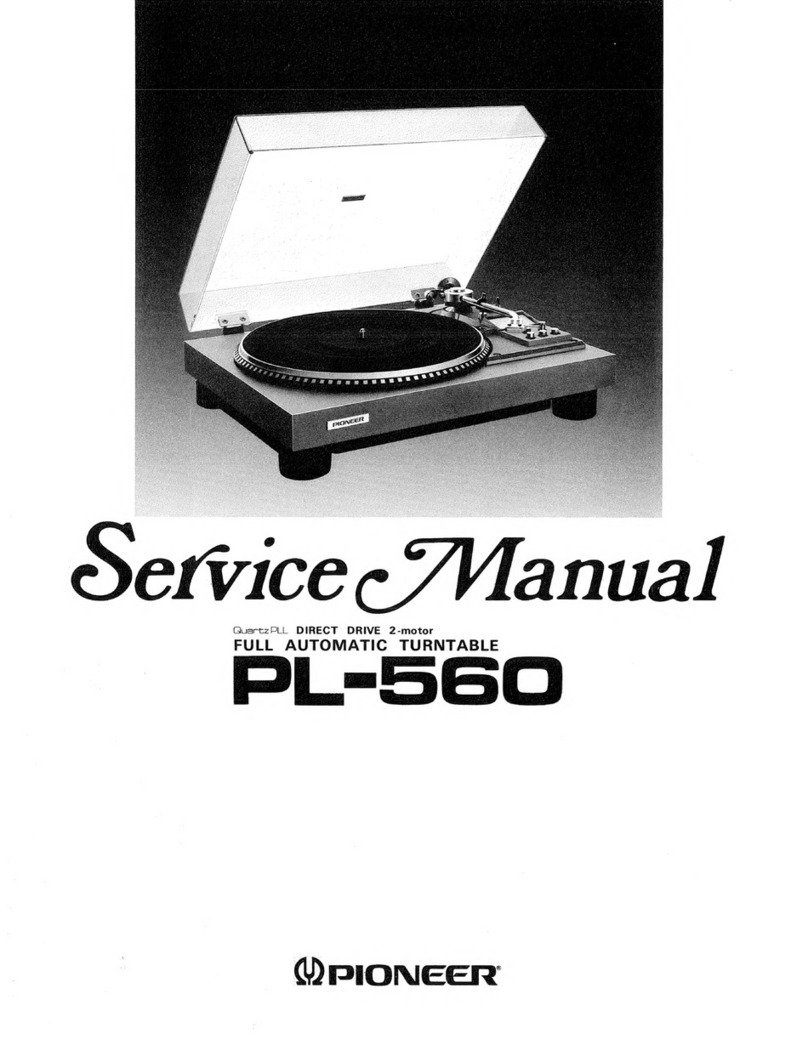

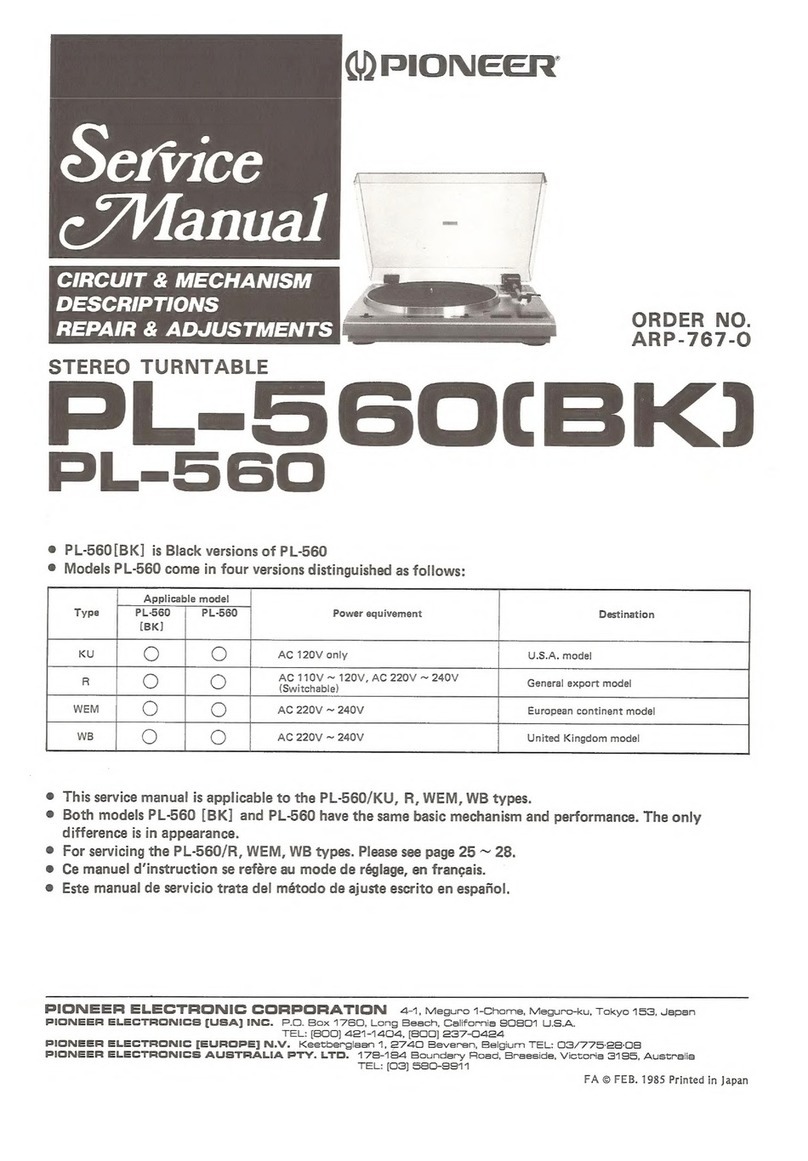

Pioneer PL-560 User manual

Pioneer

Pioneer PL-200 User manual

Pioneer

Pioneer PL-88F User manual

Pioneer

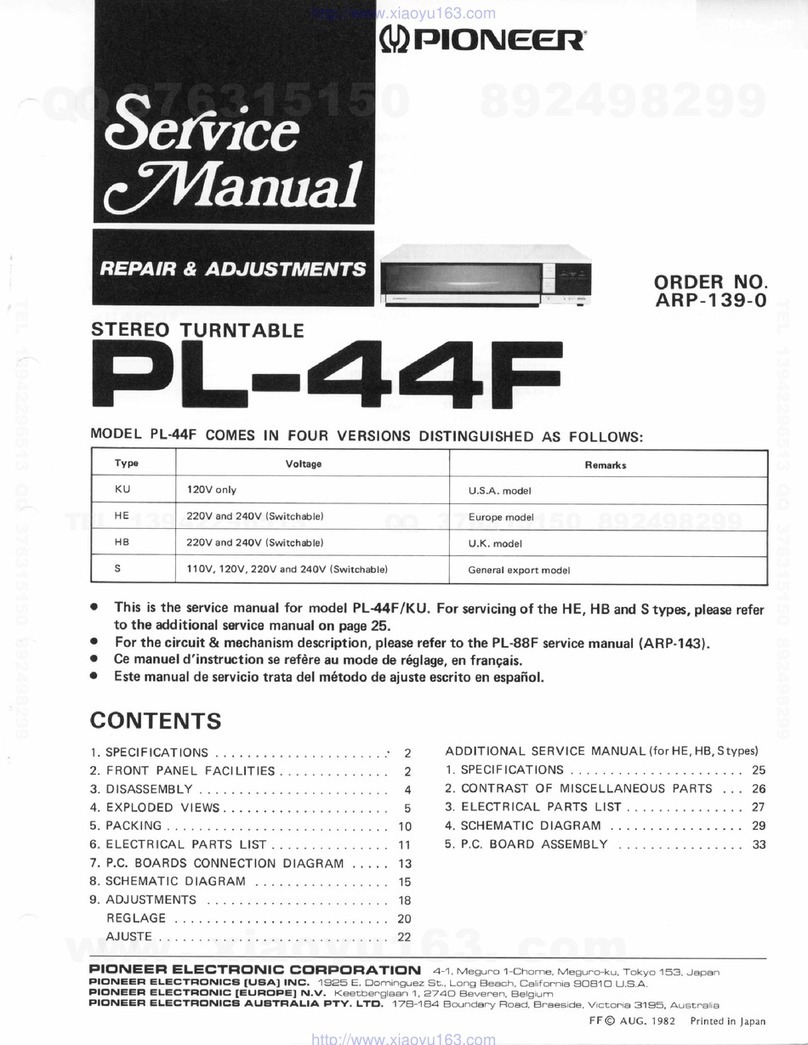

Pioneer PL-44F User manual

Pioneer

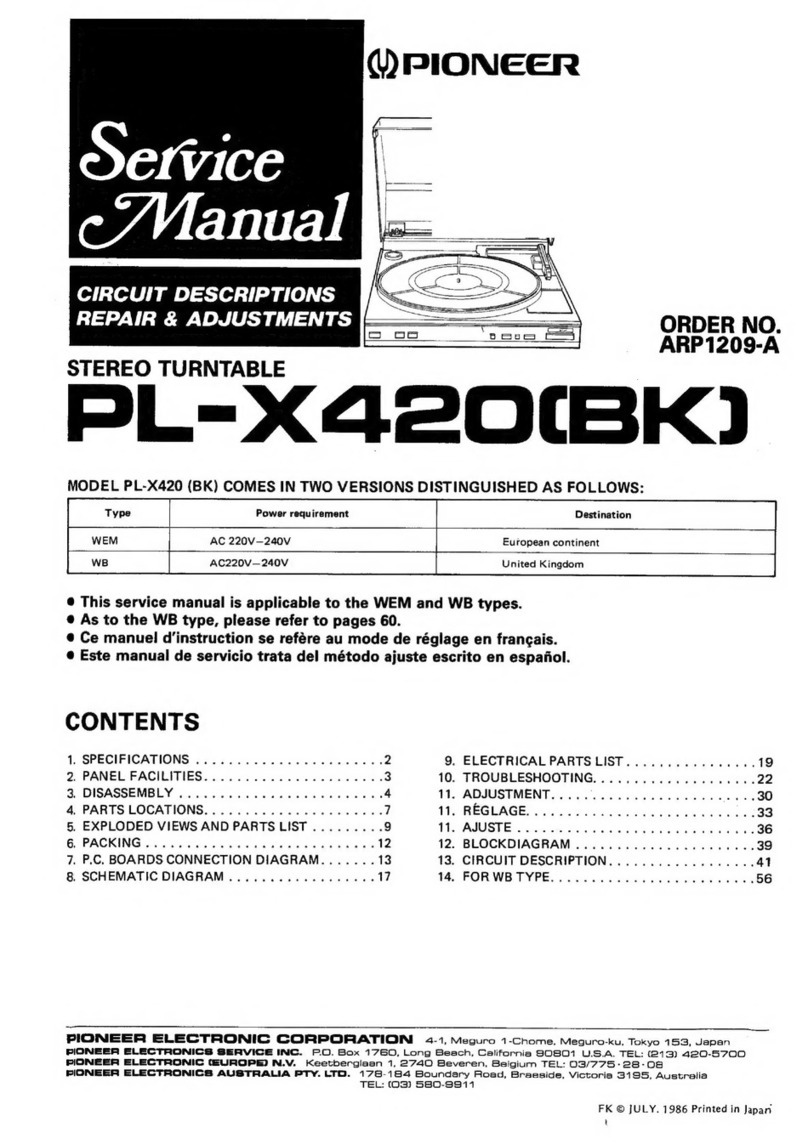

Pioneer PL-X420 User manual

Pioneer

Pioneer PL-05 User manual

Pioneer

Pioneer PL-530 User manual

Pioneer

Pioneer PL-5 User manual

Pioneer

Pioneer PL-117D User manual

Pioneer

Pioneer PL-30-K User manual

Pioneer

Pioneer AVH-P6500DVD User manual

Pioneer

Pioneer PL-510A User manual

Pioneer

Pioneer pl-930 User manual

Pioneer

Pioneer DEH-2790MP User manual

Pioneer

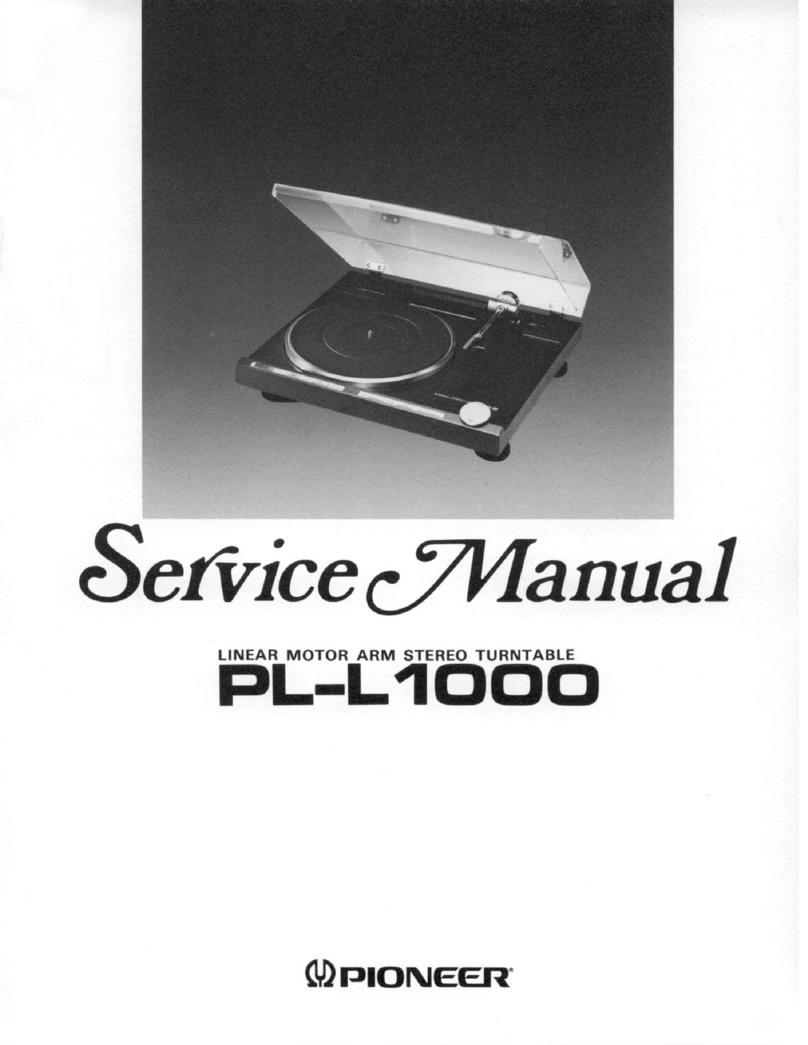

Pioneer PL-L1000 User manual

Pioneer

Pioneer PLX-1000 User manual

Pioneer

Pioneer PZ-115D User manual

Pioneer

Pioneer PL-560 User manual

Pioneer

Pioneer PL-51A User manual