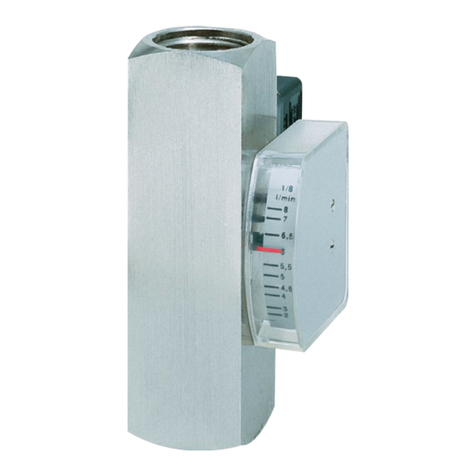

Models:

Each of the 3 types of DP05 flow switches are available

in 3 material combinations:

DP05.R… with T-fitting and pipe-thread connection

from R 3/8 to R 2 male thread

DP05.F: with T-fitting and DIN flange

from DN 10 to DN 50

aterial- T-fitting made of brass

combination A pivoting system made of brass

bellows made of st. steel 1.4571

flanges made of galvanized steel

aterial- T-fitting made of st. steel 1.4571

combination B pivoting system made of st. steel 1.4571

bellows made of st. steel 1.4571

flanges made of st. steel 1.4571

aterial- T-fitting made of PVC

combination C pivoting system made of st. steel 1.4571

bellows made of st. steel 1.4571

flanges made of PVC

DP05.A: with weld on flange

for nominal pipe size DN 65 to DN 600

aterial- housing made of brass

combination A pivoting system made of brass

bellows made of st. steel 1.4571

weld-on flange made of steel,

coated, DN 25

aterial- housing made of st. steel 1.4571

combination B pivoting system made of st. steel 1.4571

bellows made of st. steel 1.4571

weld-on flange made of st. steel 1.4571,

DN 25

Dimensions:

Order Code:

Order number: DP05.

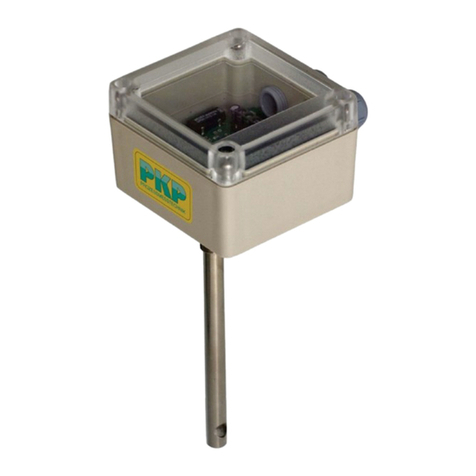

Paddle-bellows flow switch

R025. B

.

1. 20-100

Process connection

(xx= nominal pipe size):

R0xx = with male thread (only R 3/8 to R 2)

F0xx = with flange (only DN 10 to DN 50)

xxx = with weld-on-flange (from DN 40 to DN 600)

aterial combination:

= brass / stainless steel / steel zinc plated

B = completely made of stainless steel

C = PVC / stainless steel (not for DP05. ..)

Switching output:

1 = 1 microswitch (250 V / 10 )

2 = 2 microswitches (250 V / 5 )

Switching range:

xxxx-xxxx = min. - max. switch point (see table „Measuring ranges“)

Additional s ecifications:

• medium density and viscosity (if different from water)

• rocess ressure and tem erature

• mounting osition and direction of flow

• ratings of electrical connections

Measuring ranges:

Process-

connection

DP05.R...

DP05.F...

Flow rate

[l/min]

Flow-

ratio

Process-

connection

DP05.A…

Flow rate

[m³/h]

Flow-

ratio

min. max. min. max.

3/8"/DN 10 1 25 1:5 DN 40 1,2 24 1:4

1/2"/DN 15 1 55 1:5 DN 50 3 36 1:4

3/4"/DN 20 5 100 1:5 DN 65 4,8 60 1:4

1"/DN 25 6 150 1:5 DN 80 7,2 90 1:4

1 1/4"/DN 32 10 250 1:5 DN 100 12 144 1:4

1 1/2"/DN 40 20 400 1:5 DN 125 18 255 1:4

2"/DN 50 50 600 1:5 DN 150 24 330 1:4

Switching ranges apply to water at

20°C. Within the specified limits, all

switching ranges can be achieved,

provided that the max./min. ratio for

the switching point is not exceeded.

e.g. in the event of 1/2“: 1-5, 2-10 or

11-55 possible.

DN 200 42 600 1:4

DN 250 72 900 1:4

DN 300 102 1.200 1:4

DN 350 150 1.800 1:4

DN 400 180 2.400 1:4

DN 500 300 3.600 1:4

DN 600 420 4.500 1:4

Nominal size Installation length Z [mm] Installation height

H

[mm]

DP05.R… DP05.F…

3/8"/DN 10 135 155 145

1/2"/DN 15 135 155 145

3/4"/DN 20 135 160 145

1"/DN 25 135 160 145

1 1/4"/DN 32 170 190 150

1 1/2"/DN 40 170 190 155

2"/DN 50 170 190 160

Technical Data:

ax. pressure: 16 bar

max. med.-temperature: 100 °C (higher on request)

Accuracy: ± 5 % up to 20 l/min

± 4 % from 21…200 l/min

± 3 % > 200 l/min

Switching hysteresis: 10 % (up to 2 bar)

Contacts: microswitch, 250 V, 10

Status display:

Protection class:

glow lamp or LED

(depending on the con. voltage)

IP55 (IP65 on request)

Please specify the connection voltage 24 V or 230 V.

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • T +49 (0) 6122 7055-50

Flow