Table of contents page

1 About this operating manual........................................................................................................3

2 Device description.......................................................................................................................4

2.1 Delivery, unpacking and accessories.......................................................................................

2.2 Intended use.............................................................................................................................6

2.3 Exclusion of liability...................................................................................................................6

3 Safety instructions.......................................................................................................................7

4 Construction and function............................................................................................................8

4.1 Construction..............................................................................................................................8

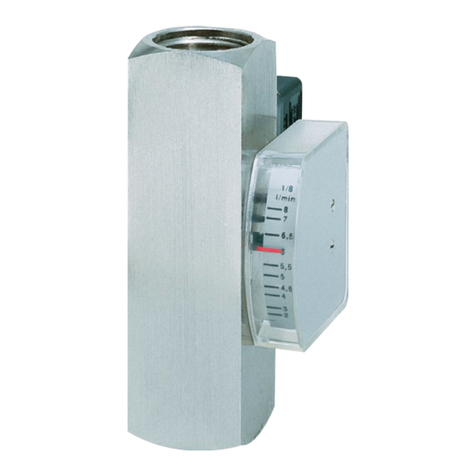

4.2 Measuring principle...................................................................................................................9

4.3 Functions..................................................................................................................................9

Installation of DM08.....................................................................................................................9

.1 Installation instructions display electronics.............................................................................10

.2 Instructions on potential equalisation and cathode protection...............................................11

.2.1 Potential equalisation..........................................................................................................11

.2.2 Cathodic protectives............................................................................................................13

.3 Sensor installation instructions...............................................................................................13

.4 Mounting.................................................................................................................................16

6 Electrical connection..................................................................................................................17

6.1 Mains and signal cable...........................................................................................................18

6.2 Electrode and magnetic current line.......................................................................................20

7 Commissioning..........................................................................................................................21

8 Operation...................................................................................................................................22

8.1 Functional classes (main menu).............................................................................................26

8.1.1 Measured values.................................................................................................................27

8.1.2 Password.............................................................................................................................29

8.1.3 Totalizer...............................................................................................................................31

8.1.4 Measurement processing....................................................................................................32

8.1. Flow.....................................................................................................................................33

8.1.6 Pulse output.........................................................................................................................36

8.1.7 Status output........................................................................................................................38

8.1.8 Current output......................................................................................................................39

8.1.9 Simulation............................................................................................................................40

8.1.10 Self-test..............................................................................................................................42

8.1.11 Settings Sensor.................................................................................................................44

9 Errors and returns......................................................................................................................48

9.1 System errors.........................................................................................................................48

9.2 Self-test errors........................................................................................................................49

9.3 Return shipment to the manufacturer..................................................................................... 0

10 Cleaning, maintenance, storage.............................................................................................. 1

10.1 Cleaning................................................................................................................................ 1

10.2 Maintenance......................................................................................................................... 1

10.3 Storage................................................................................................................................. 2

11 Disassembly and disposal....................................................................................................... 2

12 Technical data......................................................................................................................... 3

12.1 Characteristics of the DM08................................................................................................. 3

12.2 Materials...............................................................................................................................

12.3 Dimensions and weights....................................................................................................... 6

12.3.1 Compact device................................................................................................................. 6

Please keep this operating manual for future reference.

If the device is resold, please provide the operating manual along with it.