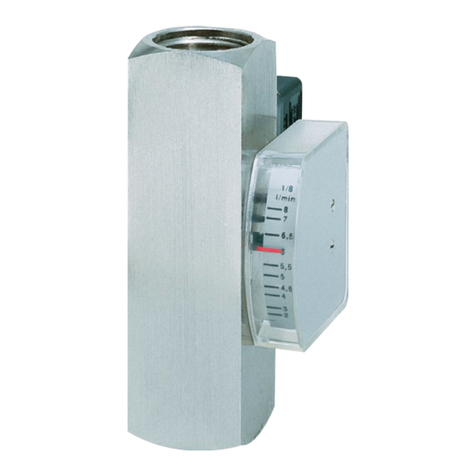

Putting into operation

As with any fine instrument, care must be taken in the installation. Your particular meter

may be of special design and may require special information, however, these tips cover

several points of concern with all models.

Please verify the following prior to installation and operation.

Yes o

— Has the piping system been cleaned and is free

of any dirt and particles?

— Has a strainer been installed at the inlet of the

meter? (only for P series)

— Is mounting position as per requirement?

— Is flow direction in accordance with the arrow

marking?

— Is operating flow within specifications? (The

maximum specified flow rate is an instrument

maximum design flow rate and is not

recommended for continuous operation. For

optimum performance a continuous flow rate

should not exceed 65% of design maximum)

— Is material compatibility verified and confirmed?

— Is operating pressure within limits?

— Have measures been taken, in case of low

viscous fluids, that the pressure drop across

the meter does not exceed 1.0 bar?

— Is operating temperature within limits?

— Have measures been taken to avoid pressure

shocks? In case a solenoid valve is used in

connection with very frequent switching cycles,

the valve should be mounted on the inlet of the

meter. To maintain full pipe conditions a non-

return valve may be mounted at the outlet.

— Does wiring comply with attached wiring

diagram?

— Have you carefully read the operating manual?

Begin start-up only once you have answere all questions with YES.

When putting into operation, always open the upstream valve slowly to apply with the fluid

pressure of the meter and avoid any pressure shocks.

Please make sure that the following parameters are always observed:

a) Maximum operating pressure is 16 bar for the M-series and 10 bar for the P-series.

b) Maximum operating temperature is 50 °C for plastic meters and 120 °C for

bronze meters with LCP chamber.

c) Meters must always be operated within the specified flow range.

d) Maximum pressure drop across the meter is 1 bar for low viscous fluids and 3,4 bar

for liquids up to maximum 800 mPas.

D D01 Instruction manual 03/2023 page 4