V7-0715

FEATURES AND SPECIFICATIONS (continued)

INSPECTION

CARE AND MAINTENANCE

RETIREMENT

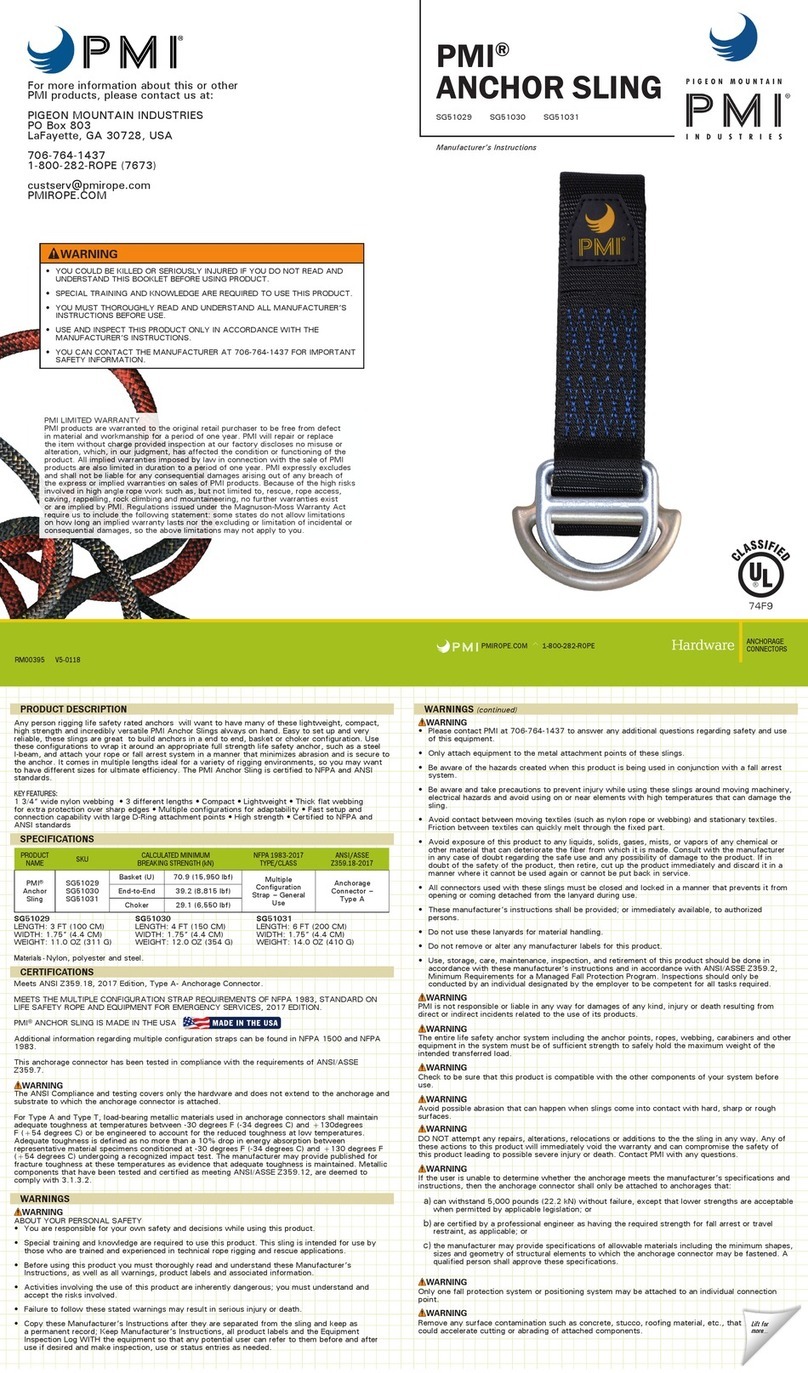

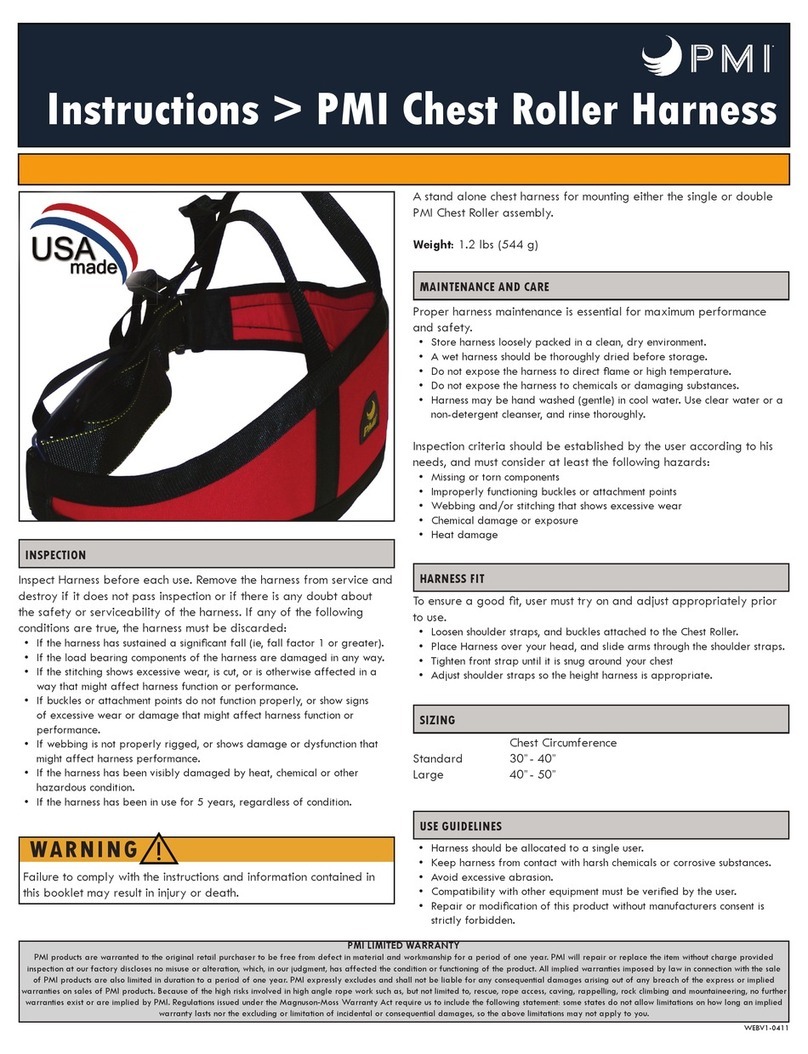

Shoulder Attachment Points

Designed for use as a

pair for positioning only

IAW ANSI Z359.1 or

NFPA 1983

Meets fall-arrest IAW ANSI Z359.1

or positioning IAW NFPA 1983.

Adjustable shoulder strap

Meets fall-arrest IAW ANSI Z359.1

or positioning IAW NFPA 1983.

Meets fall-arrest IAW ANSI Z359.1

or positioning IAW NFPA 1983.

Designed for use as a pair for

positioning only IAW ANSI Z359.1

or NFPA 1983."

Designed for use as a

pair for positioning only

IAW ANSI Z359.1 or

NFPA 1983."

Note: Accessory loops located behind the side

positioning D-rings are NOT for life safety use.

Rear waist D-Ring

Side Positioning D-Ring

Rear waist D-Ring designed for positioning

only IAW ANSI Z359.1 or NFPA 1983.

Sternal Attachment D-Ring

Side Positioning D-Ring

Waist Attachment D-Ring

Dorsal Attachment D-Ring

Quick Adjust Sliding

Bar Buckle

Certification label

can be found under

shoulder strap.

Adjustable waist and leg

straps

Quick Adjust Sliding

Bar Buckle Adjustable leg straps

Quick Adjust Sliding

Bar Buckle

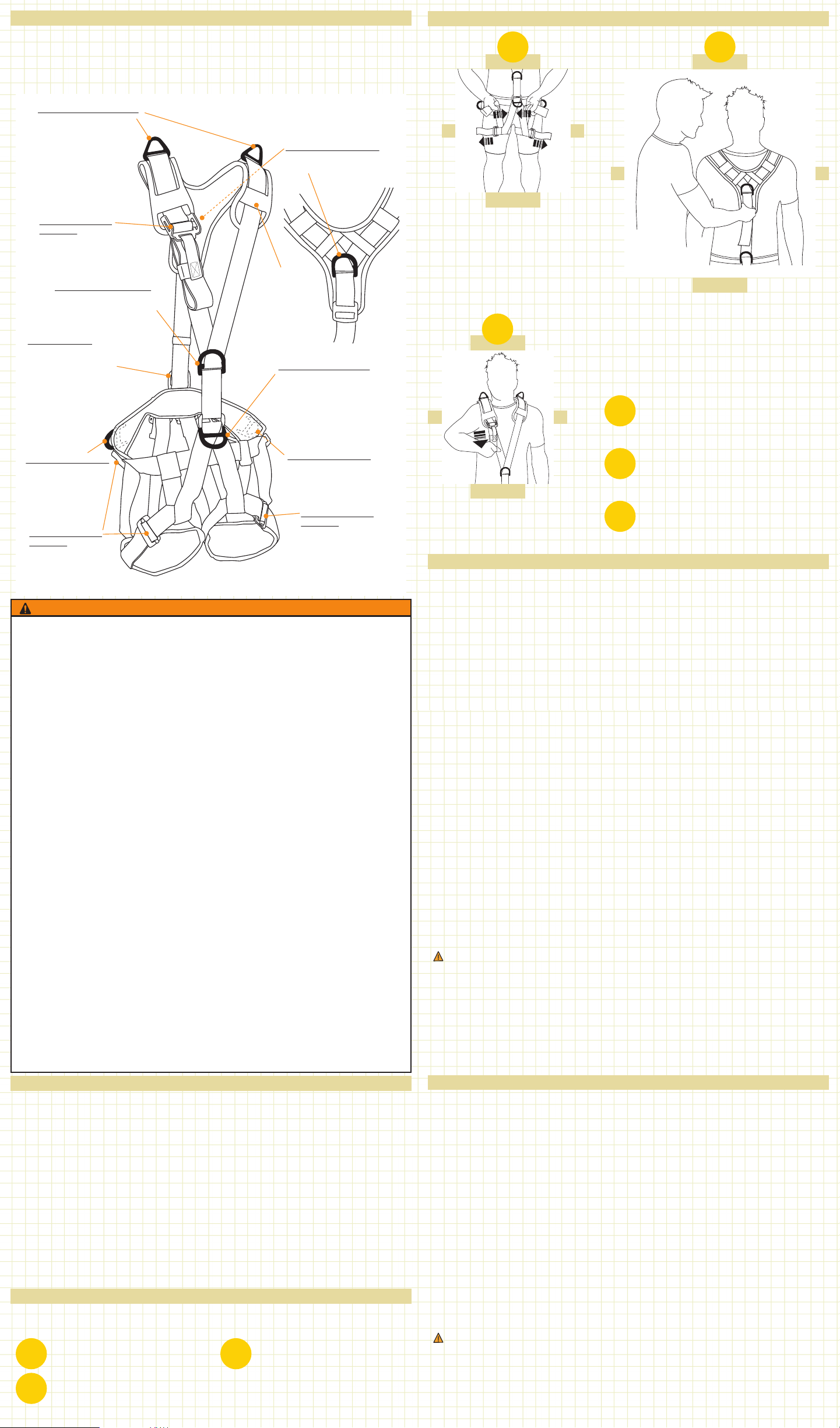

Have a partner adjust the back adjustment

strap that is attached to the dorsal D-ring

until the dorsal D-ring is positioned

between the shoulder blades. Once this

adjustment is made, it should not need to

be changed if the same person is using the

harness.

5

6

Tighten the shoulder straps until

the upper harness section is

snug on the shoulders by pulling

on the tail end of the webbing

as shown in the diagram above.

Have a partner perform a secondary

safety check of all connectors and

buckles.

9

7Secure all loose ends of straps in their

respective holders.

8Double-check all connectors and

buckles.

Tighten the waist by pulling the waist

straps towards the center D-ring

which should be centered on your

waist.

Secure the leg loops by tightening

the leg loop buckles until snug

and ensure that the leg loops are

not twisted so that they have a

comfortable t.

4

ADJUSTING THE HARNESS (continued)

ADJUSTING THE HARNESS

To ensure a good t, the user must try on and adjust appropriately prior to use.

Follow the instructions for connecting the specic chest harness to make a full body

harness before adjusting the harness.

“ADJUSTING THE HARNESS” continued on next page...

Key Features:

•8 attachment points when used with the Diamond chest harness

•Dorsal, sternal, waist, hip, shoulder, and lumbar attachments

•Fully adjustable rear leg risers and chest harness

•Available in two sizes to t 30”- 61” waists

•Ergonomic padding

•Interchangeable, removable chest harness

Your harness should be thoroughly inspected before each use. Any harness that

does not pass inspection should be immediately retired from service and discarded/

destroyed. Detailed inspection criteria must be established by the user according to

his needs. Inspections should include at a minimum:

•Examination of all load-bearing components for signs of damage.

•Inspection of all stitching for signs of wear, fraying, breaks, loosened/pulled

threads, or cuts.

•Inspection of webbing for signs of cuts, burns, discoloration, broken bers, hard/

soft sections, or excessive wear.

•Examination of buckles and attachment points for proper function.

•Examination of all metal components for corrosion, damage or sharp edges.

•Inspection of webbing rigging and buckles to ensure that harness has been

properly assembled.

•Inspection for any signs of damage from heat, chemical exposure, or other or

other environmental concerns specic to the environment where used.

•Inspection of date of manufacture and date placed in service to determine if

retirement of harness is needed (See “Retirement Criteria” section).

•Inspections should be recorded and maintained in an Equipment Inspection Log. A

sample is provided in these instructions.

Inspections should be recorded and maintained in an inspection log. A sample

inspection log is provided on back of instructions.

Maintaining your harness properly will provide a longer service life and ensure the

highest level of safety during use. The following maintenance guidelines should be

followed:

•Store harness loosely packed in a clean, dry environment.

•Thoroughly air dry a wet harness before storing it; never dry in a heated dryer.

•Keep your harness away from exposure to direct ame or high temperatures such

as in a hot car.

•Prevent exposure of your harness to chemicals or other damaging substances.

•DO NOT attempt to alter, make any modications to or attempt to repair this

harness. Any attempt to do so will void the warranty and the safety of the

harness could be compromised.

Washing: Cleaning Your Harness - If your harness is dirty, you can wash it by hand

or in a front-loading commercial washing machine. Use a PMI® Laundry bag for

keeping the harness from getting tangled/damaged when washing in a machine.

Wash harness by using cool to warm water <30°C (<86°F) with a mild soap. PMI

recommends using PMI® Rope Soap; otherwise non-detergent soaps are best. Soap

used should not contain any bleaching agents.

DO NOT:

•DO NOT use top loading washing machines with agitators because they tangle/

damage the harness severely and can cause damage to the machine.

•DO NOT use a commercial dryer to dry the harness.

•DO NOT leave a wet harness on a surface where contaminants may leach (such

as concrete).

•DO NOT expose the harness to exhaust fumes.

Disinfecting - Disinfection of a harness may occasionally become necessary, such

as when exposed to bloodborne pathogens. To disinfect a harness from suspected

bloodborne pathogens, PMI recommends following the NFPA standard for cleaning

rescue gear of bloodborne pathogens. Keeping in mind that undiluted household

bleach is known to damage nylon, NFPA calls for using a diluted solution of

household bleach to clean rescue gear. Add 60 ml of household bleach per 4 liters

of tap water. That’s about one quarter (1/4) cup of bleach per gallon of water. Be

aware that some commercial bleach solutions are stronger than the recommended

1.5% that is typical for household bleach. Soak the gear in the diluted solution for

ten minutes, then rinse thoroughly with tap water. The rinsing cycle is critical to

prevent any damage to the nylon from the bleach. It is good to soak the gear in tap

water for the same amount of time it soaked in the bleach solution. Never store gear

while it is wet.

WARNING

The use of bleach over a long period of time, in repeated uses, can cause damage

to bers such as nylon. Disinfection of the harness using bleach should be used

sparingly and only when needed.

Drying - Dry your harness in a clean, dry area out of direct sunlight. For best results,

it should be hung up to air dry in a low-humidity environment. DO NOT leave a wet

harness on a surface where contaminants may leach (such as concrete).

Write It Down - Remember to record the cleaning on the Equipment Log.

Keep It Clean - Store your harness in a clean, dark, dry environment, away from

exposure to acids, other harmful chemicals, noxious fumes or other abuse.

Retiring your harness is a judgment that is the responsibility of the user and should

be based largely on results of frequent inspections, environment and use history. If

you have any questions regarding retirement of your harness you can contact PMI.

Use the following Retirement Criteria as guidelines for retiring your harness:

•RETIRE IMMEDIATELY any harness where the stitching is cut, torn, excessively

worn or visibly damaged.

•RETIRE IMMEDIATELY if harness has been in service for 5 years or more, it must

be retired even if a visual inspection reveals no concerns.

•RETIRE IMMEDIATELY any harness whose strength may have been compromised

during use.

•RETIRE IMMEDIATELY any harness which is subjected to a major fall or

uncontrolled or excessive loading.

•RETIRE IMMEDIATELY any harness with a manufacture date which is greater than

10 years old, regardless of history and usage.

•RETIRE IMMEDIATELY any harness whose history and past usage you are

uncertain about.

•RETIRE IMMEDIATELY any harness that has been exposed to excessive heat,

direct ame or excessive abrasion.

•

•RETIRE IMMEDIATELY any harness that has been exposed to liquids, solids,

gases, mists, or vapors of any chemical or other substance that can deteriorate

the harness materials.

•RETIRE IMMEDIATELY any harness that does not pass inspection.

•RETIRE IMMEDIATELY any harness that does not pass inspection when following

the inspection procedures in these instructions, both before and after each use.

WARNING

CUT ANY RETIRED HARNESS to discourage future use and discard it entirely. A

retired harness should not be stored, kept or maintained in such a way that it could

inadvertently be used again.

ABOUT YOUR PERSONAL SAFETY

•Failure to follow these stated warnings may result in serious injury or death.

•You are responsible for your own safety and decisions while using this product.

•Activities involving the use of this product are inherently dangerous; you must

understand and accept the risks involved.

•Special training and knowledge are required to use this product. These

instructions are not an acceptable substitute for appropriate training by a qualied

instructor. The techniques employed in the safe and proper use of this equipment

may only be learned through training from an instructor who is well qualied

in all phases of vertical rope work. Such instruction will include evaluation of

your comprehension of, and ability to perform, the task required to safely and

efciently use this equipment. Never attempt to use this product until you have

received appropriate instruction and are approved to be competent by your

instructor.

•Harness should not be used near moving machinery, electrical hazards, sharp

edges, or abrasive surfaces without proper additional safety equipment in place.

In addition, harness should be carried where it will be protected, as the harness

could melt or burn and fail if exposed to ame or high temperature.

•All webbing tails should be properly secured before use.

•This harness is tted with safety buckles that ensure no slip performance when

properly rigged. If not used properly, the buckle will not hold and can result in

injury or death. Inspect the buckle on receipt and before use to ensure that the

two part buckle design is functioning properly.

•The user must have a rescue plan prepared and the means available to implement

it while wearing this harness.

•For any safety information regarding this harness refer to all Manufacturer’s/User

Instructions that shall remain available before and after use of this product.

•Use and inspect this product only in accordance with the manufacturer’s

instructions.

•The main attachment D-rings (sternal, dorsal, and waist) are for attaching to full

strength anchors used to support life-safety loads. Equipment such as life safety

lanyards, descenders, ascenders, and fall arrest systems are to be attached to

these points in accordance with applicable standards and regulations.

•The side D-rings are for work positioning only and designed to be used as a pair

with an appropriate work positioning lanyard. The side D-rings are NOT to be used

as life safety attachment points.

•The accessory loops are designed to attach equipment only and should NEVER be

used for life safety applications such as belaying, anchoring a person, or tying in

to a life safety system.

•Do not alter this product in any way.

•Keep these Manufacturer’s Instructions, all product labels and the Equipment

Inspection Log WITH the equipment so that any potential user can read them prior

to use and make entries after use.

•PMI is not responsible or liable in any way for damages of any kind, injury or

death resulting from direct or indirect incidents related to the use of its products.

•If in doubt about this use of this product or for any additional questions, please

contact PMI at 706-764-1437 before using this product.

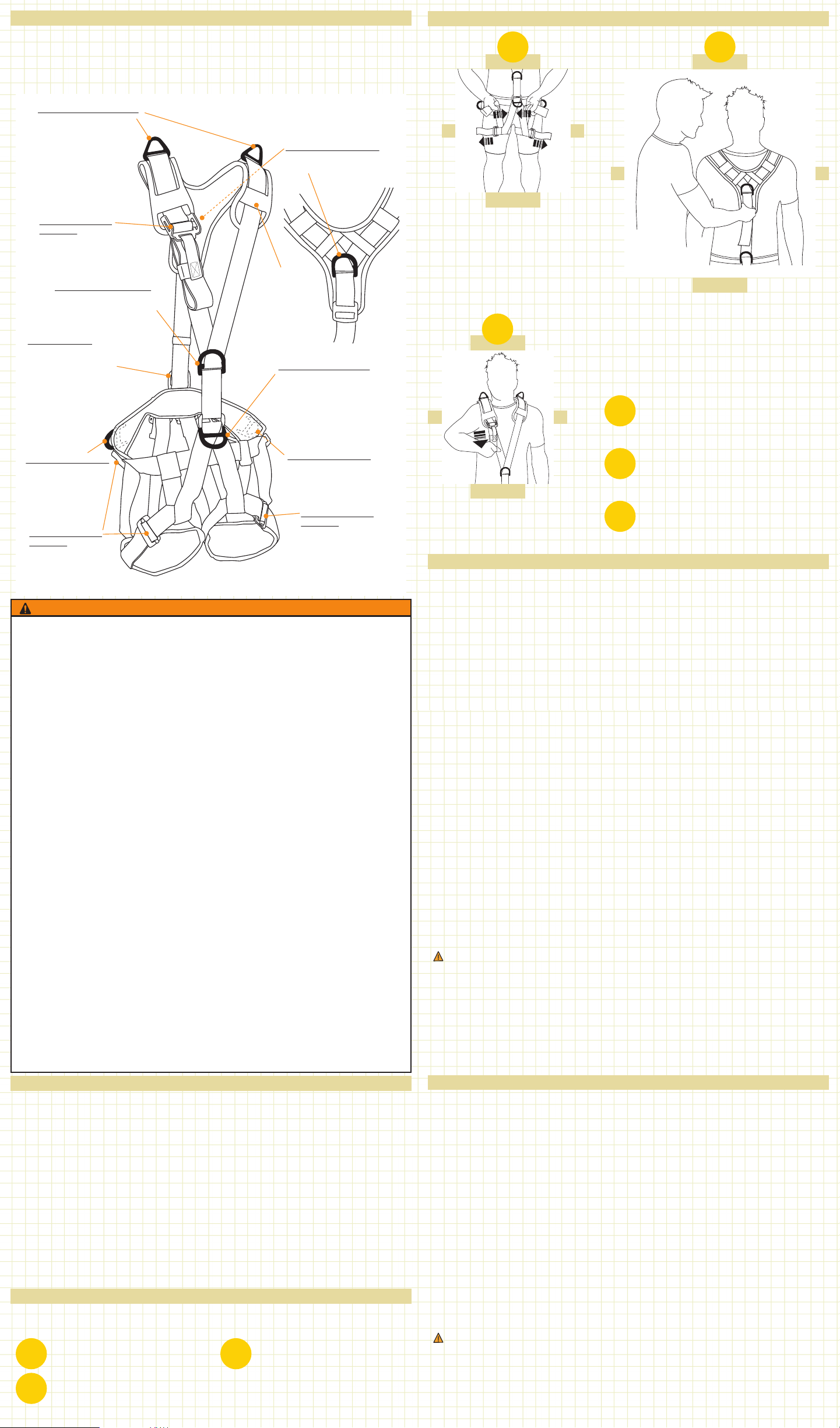

S

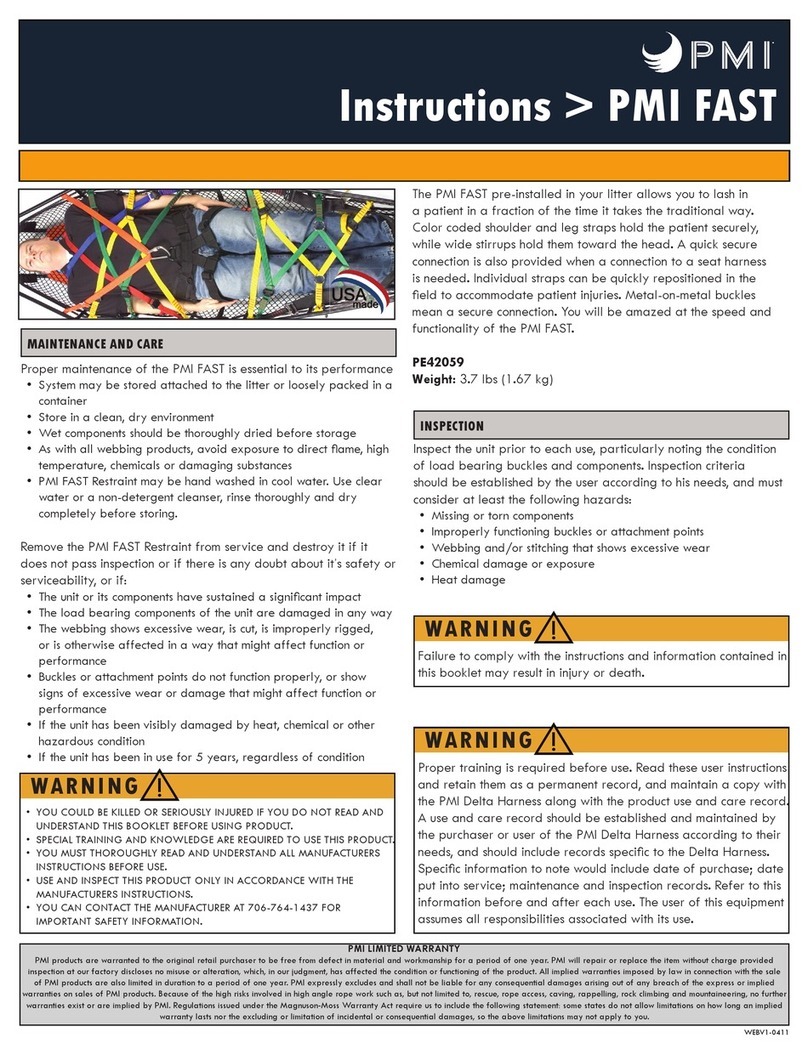

1Loosen waist belt, leg loops,

and front chest strap. 2Step through waist belt,

inserting a leg into each loop.

3Flip chest harness forward, over your head, placing head between straps.