FITTING & USE

V2-0616

INSPECTION, CARE & MAINTENANCE

INSPECTION, CARE & MAINTENANCE

Your harness should be thoroughly inspected before each use. Any harness

that does not pass inspection should be immediately retired from service and

discarded/destroyed.

Inspections should include:

• Examination of all load-bearing components for signs of damage.

• Inspection of all stitching for signs of wear, fraying, breaks, loosened/pulled

threads, or cuts.

• Inspection of webbing for signs of cuts, burns, discoloration, broken bers,

hard/soft sections, or excessive wear.

• Examination of buckles and attachment points for proper function.

• Examination of all metal components for corrosion, damage or sharp edges.

• Inspection of webbing rigging and safety buckles to ensure that harness has

been properly assembled.

• Inspection for any signs of damage from heat, chemical exposure, or various

hazardous environments.

• Inspection of date of manufacture and date placed in service to determine if

retirement of harness is needed (See “Retirement Criteria” section).

• Inspections should be recorded and maintained in an Equipment Inspection

Log. A sample is provided in these instructions.

CARE AND MAINTENANCE

Maintaining your harness properly will provide a longer service life and ensure

the highest level of safety during use.

The following maintenance guidelines should be followed:

• Store harness loosely packed in a clean, dry environment.

• Thoroughly air dry a wet harness before storing it, never dry in a heated

dryer.

• Keep your harness away from exposure to direct ame or extreme

temperatures.

• Temperature of storage or use must not exceed 176°F (80°C). The melting

point of nylon is 446°F (230°C).

• Prevent exposure of your harness to chemicals or other damaging

substances.

• No repairs or modication to this harness should be performed by anyone, or

warranty shall be voided and safety features could be compromised.

HOW TO PUT THE HARNESS ON CORRECTLY:

• To ensure a good t, the user must try on and adjust harness appropriately

prior to use.

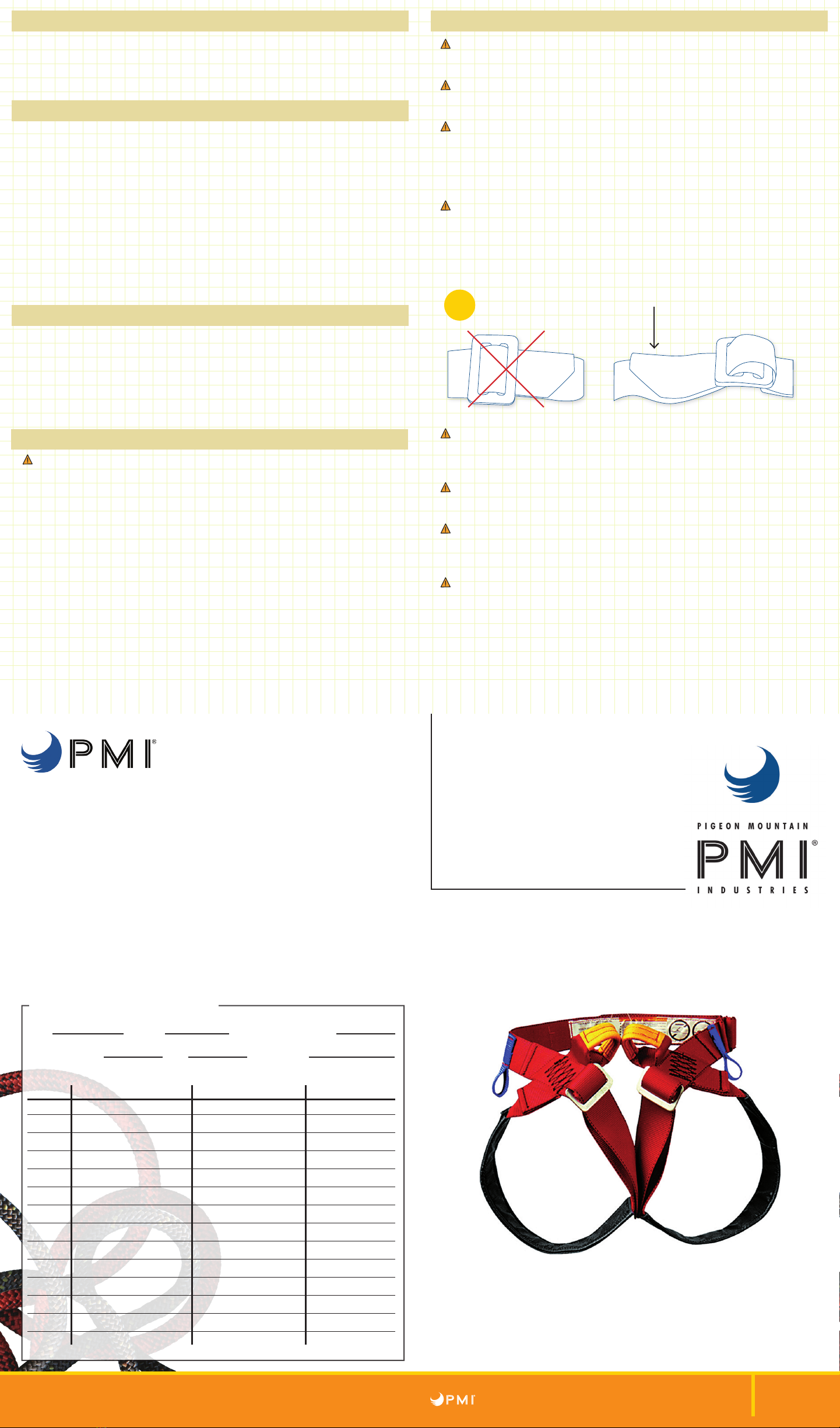

• Double Back Buckles: Loosen leg loops and waistbelt by sliding the slack

tail end of the webbing towards the buckle so that you create a bight of

webbing that is positioned in the middle of the buckle. Pull the slack bight

of webbing out of the buckle opposite of the tail end of the webbing to

adjust the harness to its largest size. Do not pull the webbing completely

through the buckle.

• Step through the waistbelt, inserting a leg into each leg loop.

• Secure the waistbelt comfortably so that it wraps over the top of the hip

bones and so that the front attachment points are about belly button level.

Do this by pushing the waistbelt webbing to create a bight of webbing in

the center of the buckle. Pull the side of the bight of webbing farthest from

the tail end of the webbing out so that the slack is taken out of the leg loop

and is snug around the waist.

• Pinch the buckle and webbing to hold in place, then with the other hand

pull the tail end of the webbing until the bight and all slack gets taken out

of the webbing and the waistbelt stays rmly in place.

• When each buckle is tightened to the desired snug t, take the tail end of

the webbing, tilt the buckle slightly and slide the webbing though the far

side of the slot in the buckle and pull tight to double back the buckle. Once

the webbing is doubled back through the buckle, there should be no less

than 3 inches of the tail end of webbing left. If there is less, then readjust

until you get 3 inches of webbing.

• Repeat this process with each of the leg loops until all applicable buckles

are doubled back.

• Use only with approved chest harness.

The design of this harness results in a variable “rise” (distance between leg

loops and waist belt) that can be easily adjusted at the leg loop safety buckles

to ensure that the harness sits comfortably and suspends the wearer properly.

If the rise is too short, there can be uncomfortable compression applied to

the crotch. This could also cause uneven top-heavy weight distribution which

could result in the wearer being ipped upside down. If the rise is too long,

the harness can put excessive compression above the hipbone. When adjusted

correctly, this harness positions the user comfortably in an upright, seated and

slightly reclined position.

PMI LIMITED WARRANTY

PMI products are warranted to the original retail purchaser to be free

from defect in material and workmanship for a period of one year. PMI

will repair or replace the item without charge provided inspection at our

factory discloses no misuse or alteration, which, in our judgment, has

affected the condition or functioning of the product. All implied warranties

imposed by law in connection with the sale of PMI products are also limited

in duration to a period of one year. PMI expressly excludes and shall not

be liable for any consequential damages arising out of any breach of the

express or implied warranties on sales of PMI products. Because of the

high risks involved in high angle rope work such as, but not limited to,

rescue, rope access, caving, rappelling, rock climbing and mountaineering,

no further warranties exist or are implied by PMI. Regulations issued under

the Magnuson-Moss Warranty Act require us to include the following

statement: some states do not allow limitations on how long an implied

warranty lasts nor the excluding or limitation of incidental or consequential

damages, so the above limitations may not apply to you.

Thank you for purchasing PMI products!

Cleaning your harness:

Washing - If your harness is dirty, you can wash it by hand or in a front-

loading commercial washing machine. Use a PMI Laundry bag for keeping

the harness from getting tangled when washing in a machine. Wash harness

by using cool to warm water <30°C (<86°F) with a mild soap. PMI

recommends using PMI Rope Soap; otherwise non-detergent soaps are best.

Soap used should not contain any bleaching agents.

DO NOT:

• DO NOT use top loading washing machines with agitators because they

tangle/damage the harness severely and can cause damage to the machine.

• DO NOT use a commercial dryer to dry the harness.

• DO NOT leave a wet harness on a surface where contaminants may leach

(such as concrete).

• DO NOT expose the harness to exhaust fumes.

Disinfecting - Disinfection of a harness may occasionally become necessary,

such as when exposed to bloodborne pathogens. To disinfect a harness

from suspected bloodborne pathogens, PMI recommends following the NFPA

standard for cleaning rescue gear of bloodborne pathogens. Keeping in mind

that undiluted household bleach is known to damage nylon, NFPA calls for

using a diluted solution of household bleach to clean rescue gear exposed

to bloodborne pathogens. Add 60 ml of household bleach per 4 liters of tap

water. That’s about one quarter (1/4) cup of bleach per gallon of water. Be

aware that some commercial bleach solutions are stronger than the 1.5%

that is typical for household bleach. Soak the gear in the diluted solution for

ten minutes, then rinse thoroughly with tap water. The rinsing cycle is critical

to prevent any damage to the nylon from the bleach. It is good to soak the

gear in tap water for the same amount of time it soaked in the bleach solution.

Never store gear while it is wet.

WARNING!

The use of bleach over a long period of time, in repeated uses, can cause

damage to bers such as nylon. Disinfection of the harness using bleach

should be used sparingly and only when needed.

Drying - Dry your harness in a clean, dry area out of direct sunlight.

For best results, it should be hanged to dry in a low-humidity environment.

Write It Down - Remember to record the cleaning on the Equipment Log.

Keep It Clean - Store your harness in a clean, dark, dry environment, away from

exposure to acids, chemicals, noxious fumes, or other harmful agents.

PRODUCT LIFETIME

Regardless of history and use, a PMI® Pit Viper Caving Harness should be

retired if it is greater than 10 years from the date of manufacture. The actual

service life of of this harness may be much less than 10 years and should be

based largely on the results of frequent inspection and use history. Material

integrity and product performance characteristics will degrade over time. PMI

recommends that you thoroughly inspect your equipment before each use and at

a minimum at least once every 6 months. Specialized training may be required

to become competent with inspecting equipment and knowing when to retire

your equipment. Good judgment, as well as proper care and inspection, are key

to making personal decisions regarding the retirement of your harness.

A signicant event with the potential to change the product should prompt you

to consider retiring it immediately even if before or after only one use. Factors

that may affect the safety of a harness depends on the type and frequency

of usage (light to heavy), the environment including harsh environments with

extreme temperatures, marine (salty or highly corrosive) environments, chemical

contact, contact with sharp edges, etc. Textiles can become dry and brittle,

plastics can weaken in areas, small cracks can form, etc. The best way to

know when a change has occurred with your harness is to implement frequent

detailed inspections before each use.

RETIREMENT CRITIERIA

• RETIRE IMMEDIATELY any harness where the stitching is cut, torn,

excessively worn or visibly damaged.

• RETIRE IMMEDIATELY any harness that is greater than 10 years old

calculated from the date of manufacture, regardless of history or use.

• RETIRE IMMEDIATELY any harness whose strength may have been

compromised during use.

• RETIRE IMMEDIATELY any harness which is subjected to a major fall or

uncontrolled or excessive loading.

• RETIRE IMMEDIATELY any harness whose history and past usage you are

uncertain about.

• RETIRE IMMEDIATELY any harness that has been exposed to heat, direct

ame or excessive abrasion.

• RETIRE IMMEDIATELY any harness that has been exposed to liquids,

solids, gases, mists, or vapors of any chemical or other substance that can

deteriorate the harness materials.

• RETIRE IMMEDIATELY any harness that does not pass inspection.

• RETIRE IMMEDIATELY any harness that raises any doubt about its safety or

serviceability.

WARNING!

CUT RETIRED harnesses to discourage future use and discard it entirely.

A retired harness should not be stored, kept or maintained in such a way that

it could inadvertently be used again.