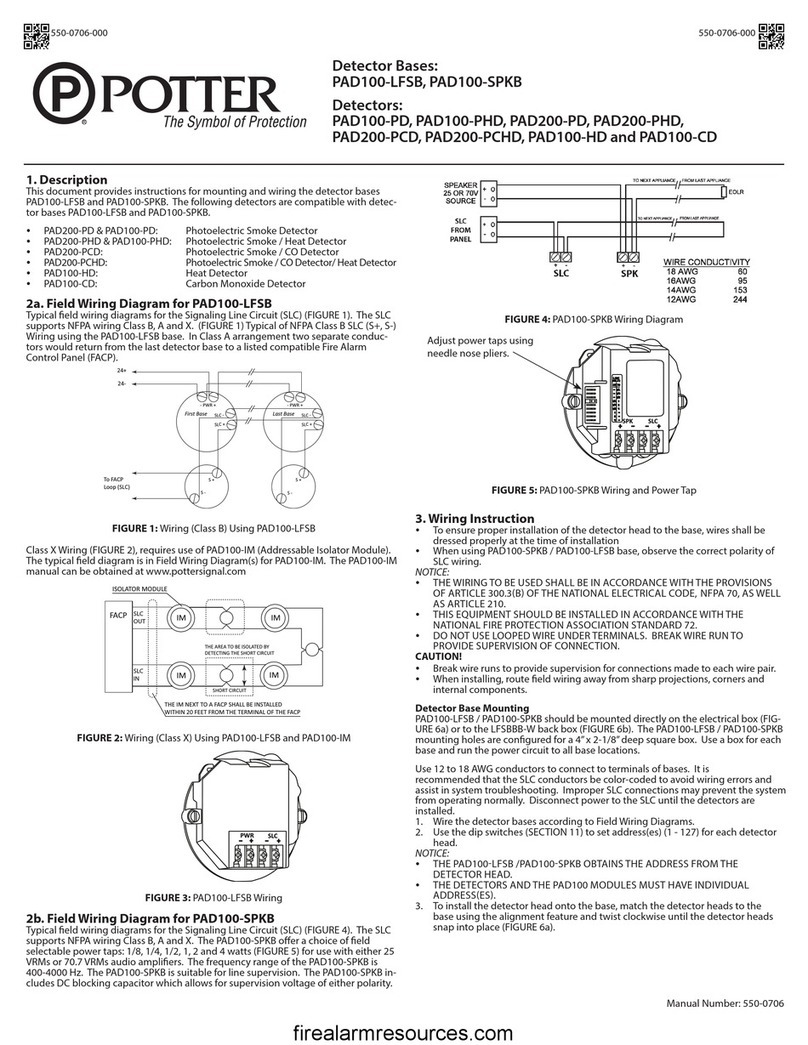

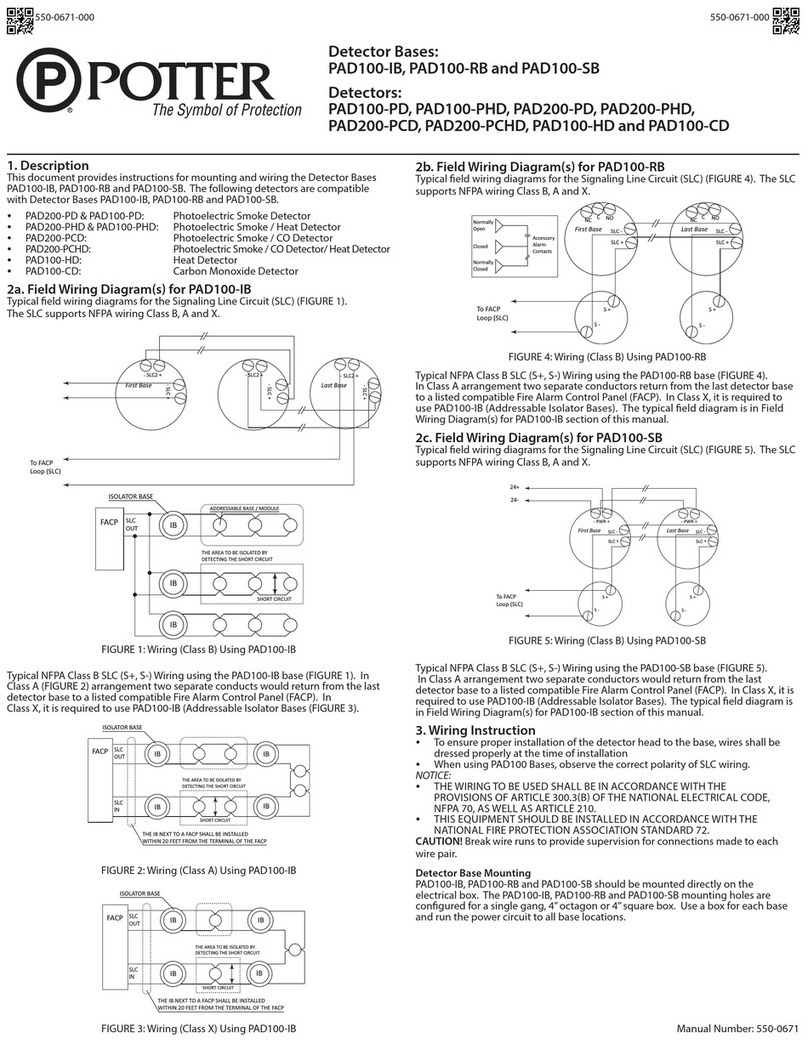

All terminals are power limited and should be wired in

accordance with the requirements of NFPA 70 (NEC) and

NFPA 72 (National Fire Alarm Code). Failure to follow the

wiring diagrams in the following pages will cause the system

to not operate as intended.

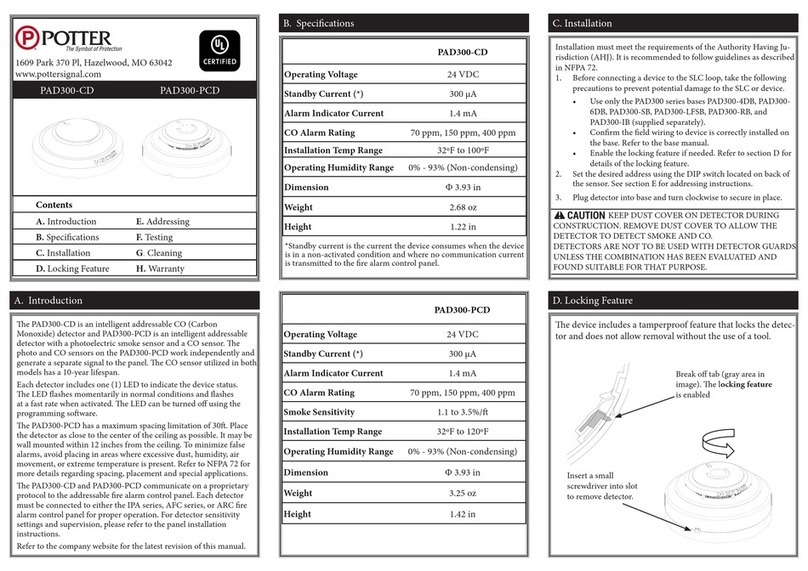

1. Before connecting a device to the SLC loop, take the

following precautions to prevent potential damage to the

SLC or device.

• Power to the SLC is removed.

• Field wiring on device is correctly installed on the base

(supplied separately). Beware of the polarity marked next

to the terminals. S+ is positive and S- is negative.

• Use wires between size 22 AWG to 12 AWG.

• Strip all wires 1/4 inch from their edges shown here:

• Field wiring has no open or short circuit.

2. Connect PWR to 24VDC+/-. Synchronization requires

connection to the NAC or I/O output of a compatible panel.

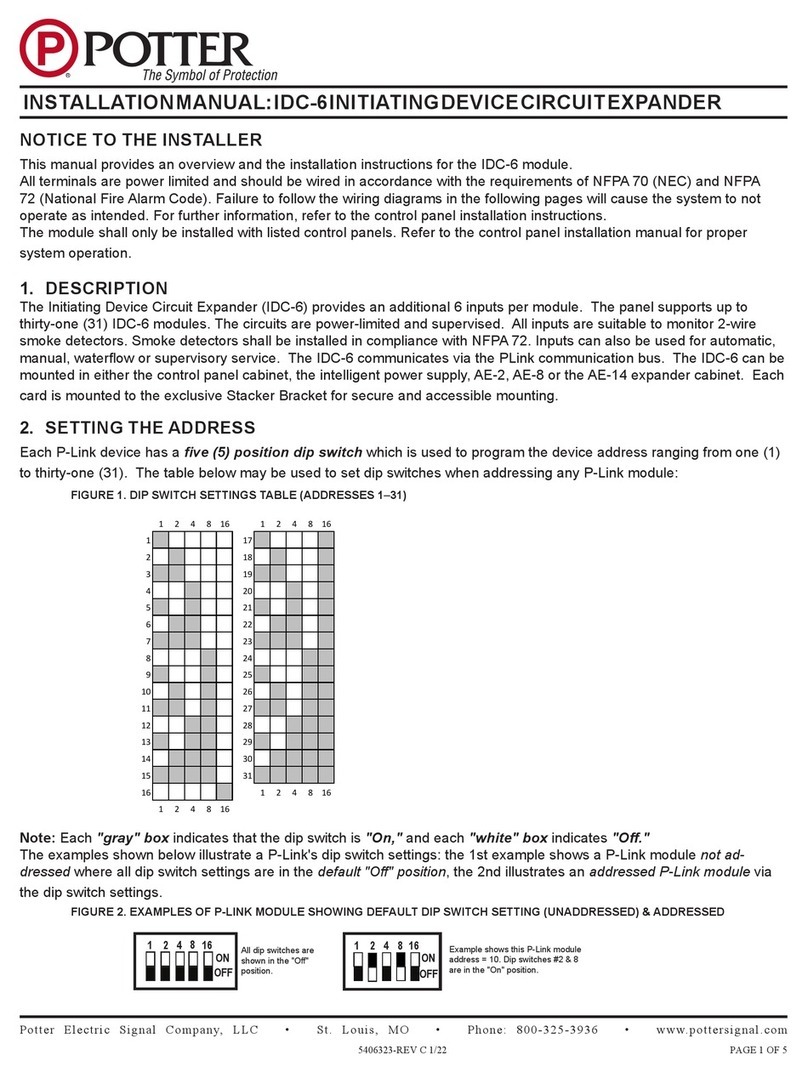

3. Set the desired address using the DIP switch located on back

of the sensor. Refer to addressing instruction in the manual of

detector.

4. Plug sensor on base and turn clockwise to secure in place. Refer

to section E for detail of the locking feature.

e product may be installed as a Class B, Class A or Class X.

Class B:

D. Wiring

1/4 inch

DO NOT LOOP WIRE AROUND TERMINAL.

SEPARATE WIRES TO ALLOW FOR CONNECTION

SUPERVISION.

e device includes a tamperproof feature that locks the detector and

does not allow removal without the use of a tool.

Class A and X Wiring:

NOTE: THE BUILT-IN ISOLATION IN EACH PAD300 SERIES

DETECTOR CONFIGURED IN CLASS A WITH THE SOUNDER

BASE ALSO MAKES THE INSTALLATION A CLASS X.

NOTE: CLASS X REQUIRES A CLOSE NIPPLE OR CONDUIT

CONNECTION TO EVERY DEVICE.

E. Locking Feature

Break o tab (gray area in

image). e locking featurelocking feature is

enabled

Insert a small

screwdriver into slot

to remove detector.

It is important to test the sounder aer installation and periodically.

Please follow the instructions below.

1. From keypad menu, access Point Control menu function

(Option 5 – System Tools and then Option 2 – Point Control).

2. Select Built In SLC (Assuming Sounder Base is connected to

Panel’s built in SLC Circuit and not SLC expansion card).

3. Enter the Device Address of the Detector with Sounder Base.

4. Press Enter Button and it should display the device address.

5. Press UP Arrow Button to scroll to the Sounder Base. Panel

display changes to show the Sounder Base associated with the

detector.

6. Press Enter Button. Panel Display should read “Enter Key Will

Activate Output.”

7. Press Enter Button again to activate sounder base.

Test synchronization by commanding a group of sounder bases.

Units failing the test should be immediately serviced.

POTTER warrants that the equipment herein shall conform to

said descriptions as to all armation of fact and shall be free from

defects of manufacture, labeling, and packaging for a period of ve

(5) years from the invoice date to the original purchaser, provided

that representative samples are returned to POTTER for inspection.

e product warranty period is stated on the exterior of the product

package. Upon a determination by POTTER that a product is not as

warranted, POTTER shall, at its exclusive option, replace or repair

said defective product or parts thereof at its own expense, except

that Purchaser shall pay all shipping, insurance, and similar charges

incurred in connection with the replacement of the defective product

or parts thereof. is Warranty is void in the case of abuse, misuse,

abnormal usage, faulty installation, or repair by unauthorized per-

sons, or if for any other reason POTTER determines that said prod-

uct is not operating properly as a result of causes other than defective

manufacture, labeling, or packaging.

G. Warranty

F. Testing

NOTIFY APPROPRIATE AUTHORITY BEFORE

TESTING THE SENSOR. PLACE FIRE PANEL IN WALK TEST

MODE BEFORE CONDUCTING THE FOLLOWING TEST. REFER

TO THE PANEL INSTALLATION MANUAL FOR DETAIL.

Manual Number:

54035220X_A

Manual Issue Date:

07/01/2022