NOTE: Before cleaning, notify the proper authorities that the system

is undergoing maintenance. Disable the loop or system undergoing

maintenance to prevent unwanted alarms. It is recommended that the

detector be removed from its mounting base for easier cleaning and

that detectors be cleaned at least once a year. Use a vacuum cleaner

remove dust from the sensing chamber.

POTTER warrants that the equipment herein shall conform to

said descriptions as to all armation of fact and shall be free from

defects of manufacture, labeling, and packaging for a period of ve

(5) years from the invoice date to the original purchaser, provided

that representative samples are returned to POTTER for inspection.

e product warranty period is stated on the exterior of the product

package. Upon a determination by POTTER that a product is not as

warranted, POTTER shall, at its exclusive option, replace or repair

said defective product or parts thereof at its own expense, except

that Purchaser shall pay all shipping, insurance, and similar charges

incurred in connection with the replacement of the defective product

or parts thereof. is Warranty is void in the case of abuse, misuse,

abnormal usage, faulty installation, or repair by unauthorized per-

sons, or if for any other reason POTTER determines that said prod-

uct is not operating properly as a result of causes other than defective

manufacture, labeling, or packaging.

H. Warranty

G. CleaningE. Addressing

According to NFPA72, remote testing is NOT necessary

for duct applications. But if testing is still desired, it is

recommended to follow guidelines as described below.

Smoke Aerosol Test

Use a canned aerosol to spray directly to the side of the

detector. SmokeCheck 25S from HSI Fire and Smoke Centurion

from SDi are acceptable. Please contact local re and safety

equipment distributors to see which products are available.

Units failing the aerosol test should be immediately cleaned.

If cleaning cannot restore the unit to normal, it should be

replaced.

Air Sampling Verication

is detector is designed to be used in air handling systems with

air velocities of 300 to 3000 feet per minute. To ensure that the air

velocity in the duct falls within these parameters, use a velocity meter

(anemometer) to check the air velocity in the duct.

Magnet Test

e magnet test provides a quick test to verify the connections

and the detector electronically. is test should not replace the

aerosol test, which is required as part of regular testing and

maintenance per NFPA 72.

1. Hold the test magnet in the magnet test area as shown

below.

2. e LED ashes rapidly to indicate the detector is in

alarm.

3. Remove magnet.

4. Alarm on the re alarm panel should be reset.

5. If the unit fails the magnet test, test the unit with

an aerosol testing spray to conrm any failures.

F. Testing

NOTIFY APPROPRIATE AUTHORITY BEFORE

TESTING THE DETECTOR. PLACE FIRE PANEL IN

WALK TEST

MODE BEFORE CONDUCTING THE FOLLOWING TEST. REFER

TO THE PANEL INSTALLATION MANUAL FOR DETAIL.

Magnet Location

Pry the four (4) elastic arms

gently with a small, slotted

screwdriver to remove detector

cover.

Pry the elastic arm gently with a small, slotted screwdriver to

remove cage for cleaning.

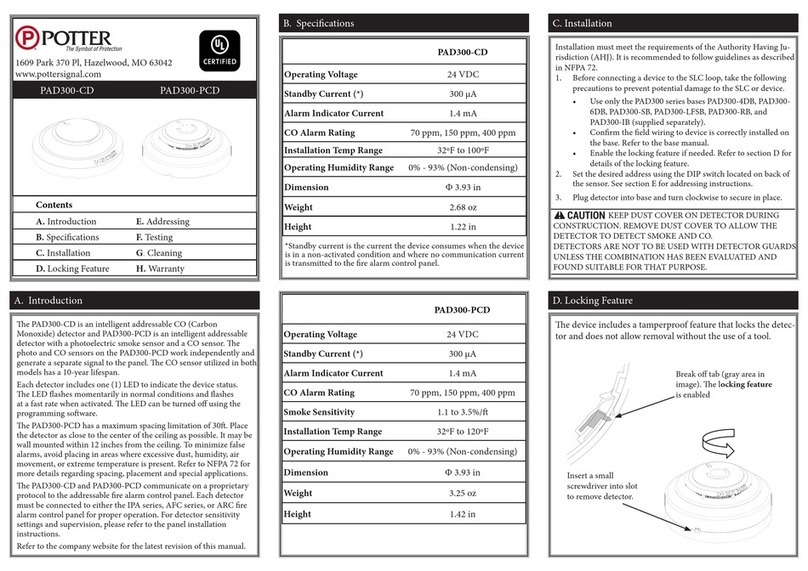

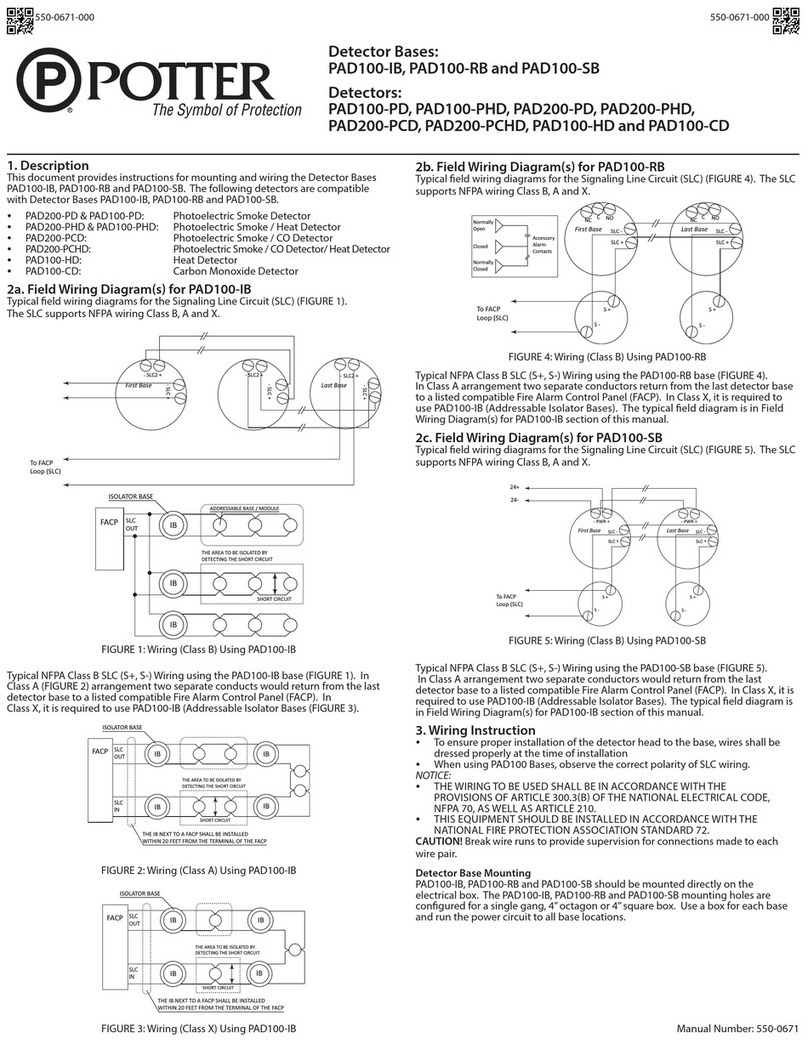

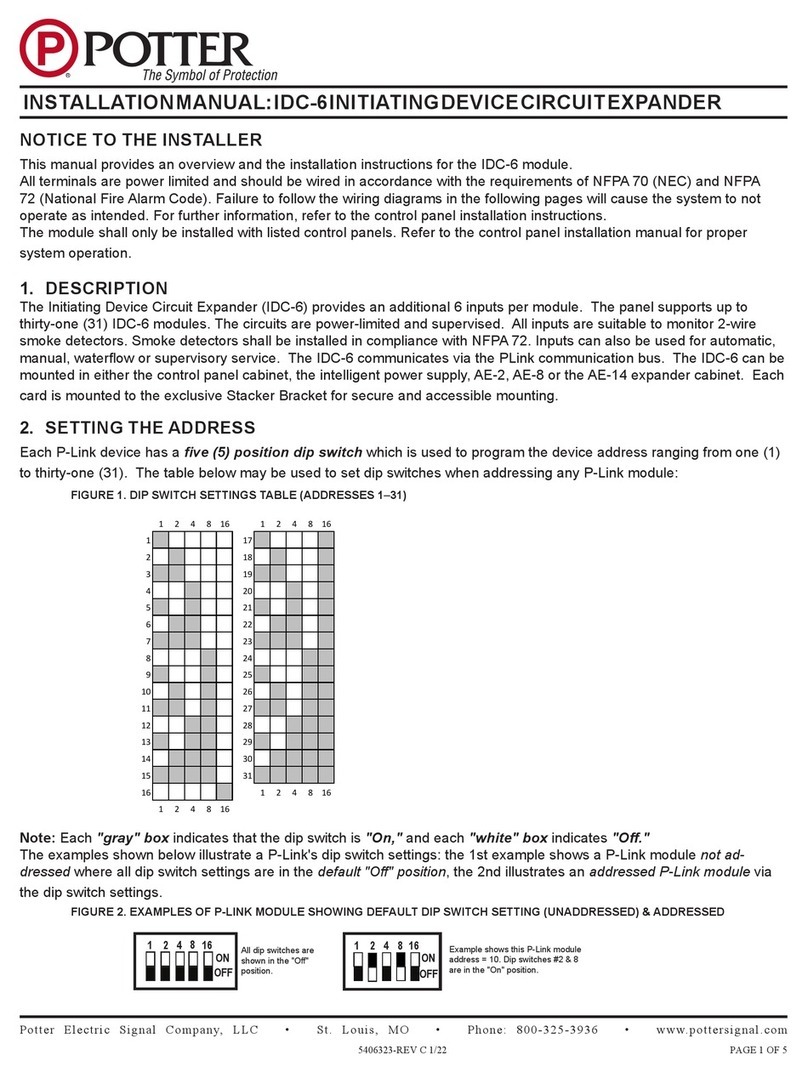

Detector address can be congured using the

table below for DIP switch position settings.

POS DIP Switch on POS DIP Switch on POS DIP Switch on

1 1 43 1,2,4,6 85 1,3,5,7

2 2 44 3,4,6 86 2,4,5,7

3 1,2 45 1,3,4,6 87 1,2,3,5,7

4 3 46 2,3,4,6 88 4,5,8

5 1,3 47 1,2,3,4,6 89 1,4,5,7

6 2,3 48 5,6 90 2,4,5,7

7 1,2,3 49 1,5,6 91 1,2,4,5,7

8 4 50 2,5,6 92 3,4,5,7

9 1,4 51 1,2,5,6 93 1,3,4,5,7

10 2,4 52 3,5,6 94 2,3,4,5,7

11 1,2,4 53 1,3,5,6 95 1,2,3,4,5,7

12 3,4 54 2,3,5,6 96 6,7

13 1,3,4 55 1,2,3,5,6 97 1,6,7

14 2,3,4 56 4,5,6 98 2,6,7

15 1,2,3,4 57 1,4,5,6 99 1,2,6,7

16 5 58 2,4,5,6 100 3,6,7

17 1,5 59 1,2,4,5,6 101 1,3,6,7

18 2,5 60 3,4,5,6 102 2,3,6,7

19 1,2,5 61 1,3,4,5,6 103 1,2,3,6,7

20 3,5 62 2,3,5,5,6 104 4,6,7

21 1,3,5 63 1,2,3,4,5,6 105 1,4,6,7

22 2,3,5 64 7 106 2,4,6,7

23 1,2,3,5 65 1,7 107 1,2,4,6,7

24 4,5 66 2,7 108 3,4,6,7

25 1,4,5 67 1,2,7 109 1,3,4,6,7

26 2,4,5 68 3,7 110 2,3,4,6,7

27 1,2,4,5 69 1,3,7 111 1,2,3,4,6,7

28 3,4,5 70 2,3,7 112 5,6,7

29 1,3,4,5 71 1,2,3,7 113 1,5,6,7

30 2,3,4,5 72 4,7 114 2,5,6,7

31 1,2,3,4,5 73 1,2,4,7 115 1,2,5,6,7

32 6 74 3,4,7 116 3,5,6,7

33 1,6 75 1,3,4,7 117 1,3,5,6,7

34 2,6 76 2,3,4,7 118 2,3,5,6,7

35 1,2,6 77 1,3,4,7 119 1,2,3,5,6,7

36 3,6 78 2,3,4,7 120 4,5,6,7

37 1,3,6 79 1,2,3,4,7 121 1,4,5,6,7

38 2,3,6 80 5,7 122 2,4,5,6,7

39 1,2,3,6 81 1,5,7 123 1,2,4,5,6,7

40 4,6 82 2,5,7 124 3,4,5,6,7

41 1,4,6 83 1,2,5,7 125 1,3,4,5,6,7

42 2,4,6 84 3,5,7 126 2,3,4,5,6,7

127 1,2,3,4,5,6,7 Manual Number:

54035217X_A

Manual Issue Date:

07/01/2022