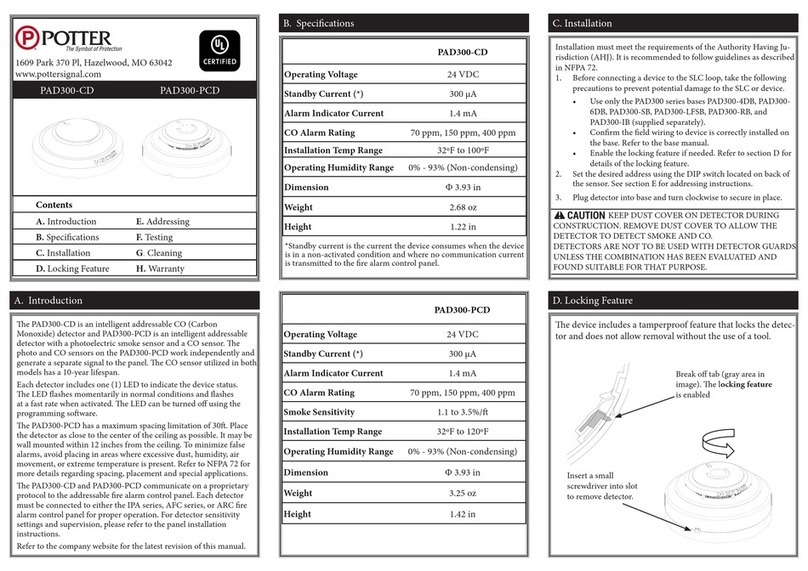

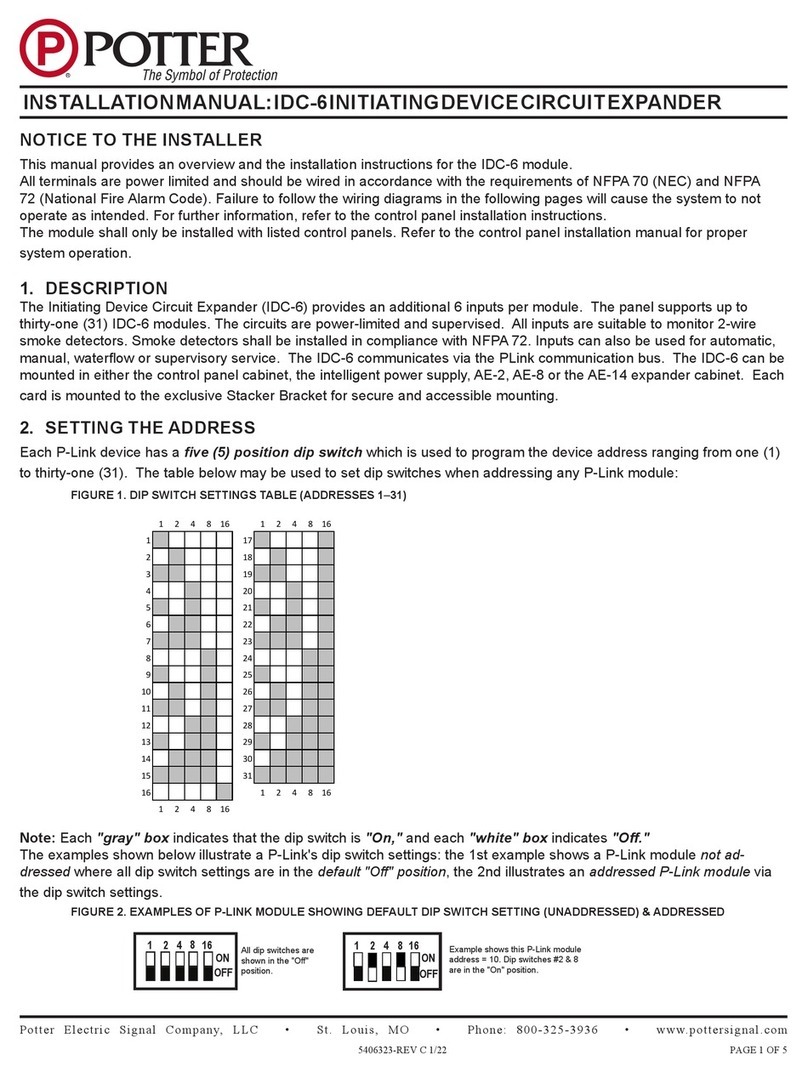

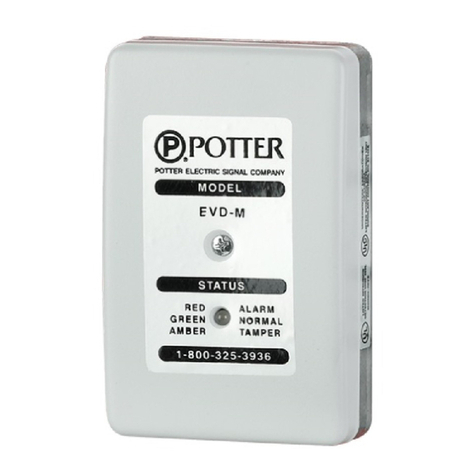

E. Addressing

Detector address can be congured using the

table below for DIP switch position settings.

POS DIP Switch on POS DIP Switch on POS DIP Switch on

1 1 43 1,2,4,6 85 1,3,5,7

2 2 44 3,4,6 86 2,4,5,7

3 1,2 45 1,3,4,6 87 1,2,3,5,7

4 3 46 2,3,4,6 88 4,5,8

5 1,3 47 1,2,3,4,6 89 1,4,5,7

6 2,3 48 5,6 90 2,4,5,7

7 1,2,3 49 1,5,6 91 1,2,4,5,7

8 4 50 2,5,6 92 3,4,5,7

9 1,4 51 1,2,5,6 93 1,3,4,5,7

10 2,4 52 3,5,6 94 2,3,4,5,7

11 1,2,4 53 1,3,5,6 95 1,2,3,4,5,7

12 3,4 54 2,3,5,6 96 6,7

13 1,3,4 55 1,2,3,5,6 97 1,6,7

14 2,3,4 56 4,5,6 98 2,6,7

15 1,2,3,4 57 1,4,5,6 99 1,2,6,7

16 5 58 2,4,5,6 100 3,6,7

17 1,5 59 1,2,4,5,6 101 1,3,6,7

18 2,5 60 3,4,5,6 102 2,3,6,7

19 1,2,5 61 1,3,4,5,6 103 1,2,3,6,7

20 3,5 62 2,3,5,5,6 104 4,6,7

21 1,3,5 63 1,2,3,4,5,6 105 1,4,6,7

22 2,3,5 64 7 106 2,4,6,7

23 1,2,3,5 65 1,7 107 1,2,4,6,7

24 4,5 66 2,7 108 3,4,6,7

25 1,4,5 67 1,2,7 109 1,3,4,6,7

26 2,4,5 68 3,7 110 2,3,4,6,7

27 1,2,4,5 69 1,3,7 111 1,2,3,4,6,7

28 3,4,5 70 2,3,7 112 5,6,7

29 1,3,4,5 71 1,2,3,7 113 1,5,6,7

30 2,3,4,5 72 4,7 114 2,5,6,7

31 1,2,3,4,5 73 1,2,4,7 115 1,2,5,6,7

32 6 74 3,4,7 116 3,5,6,7

33 1,6 75 1,3,4,7 117 1,3,5,6,7

34 2,6 76 2,3,4,7 118 2,3,5,6,7

35 1,2,6 77 1,3,4,7 119 1,2,3,5,6,7

36 3,6 78 2,3,4,7 120 4,5,6,7

37 1,3,6 79 1,2,3,4,7 121 1,4,5,6,7

38 2,3,6 80 5,7 122 2,4,5,6,7

39 1,2,3,6 81 1,5,7 123 1,2,4,5,6,7

40 4,6 82 2,5,7 124 3,4,5,6,7

41 1,4,6 83 1,2,5,7 125 1,3,4,5,6,7

42 2,4,6 84 3,5,7 126 2,3,4,5,6,7

127 1,2,3,4,5,6,7

Testing must meet the requirements of the Authority Having

Jurisdiction (AHJ). It is recommended to follow guidelines as

described in NFPA 72.

It is important to test the product aer installation and

periodically to ensure it functions probably.

Heat Test

Use hair dryer or heat gun to direct the heat toward the side

of the detector. Keep at a distance of 6 in or 15 cm to avoid

overheating.

Units failing the heat test should be serviced.

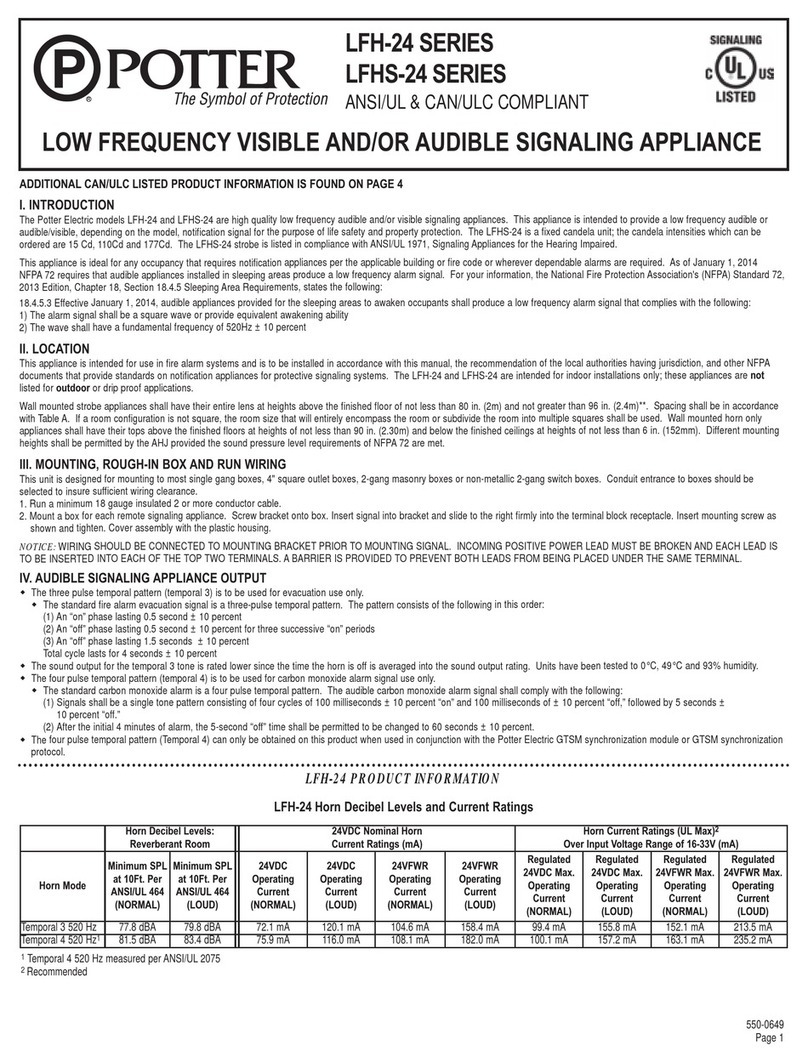

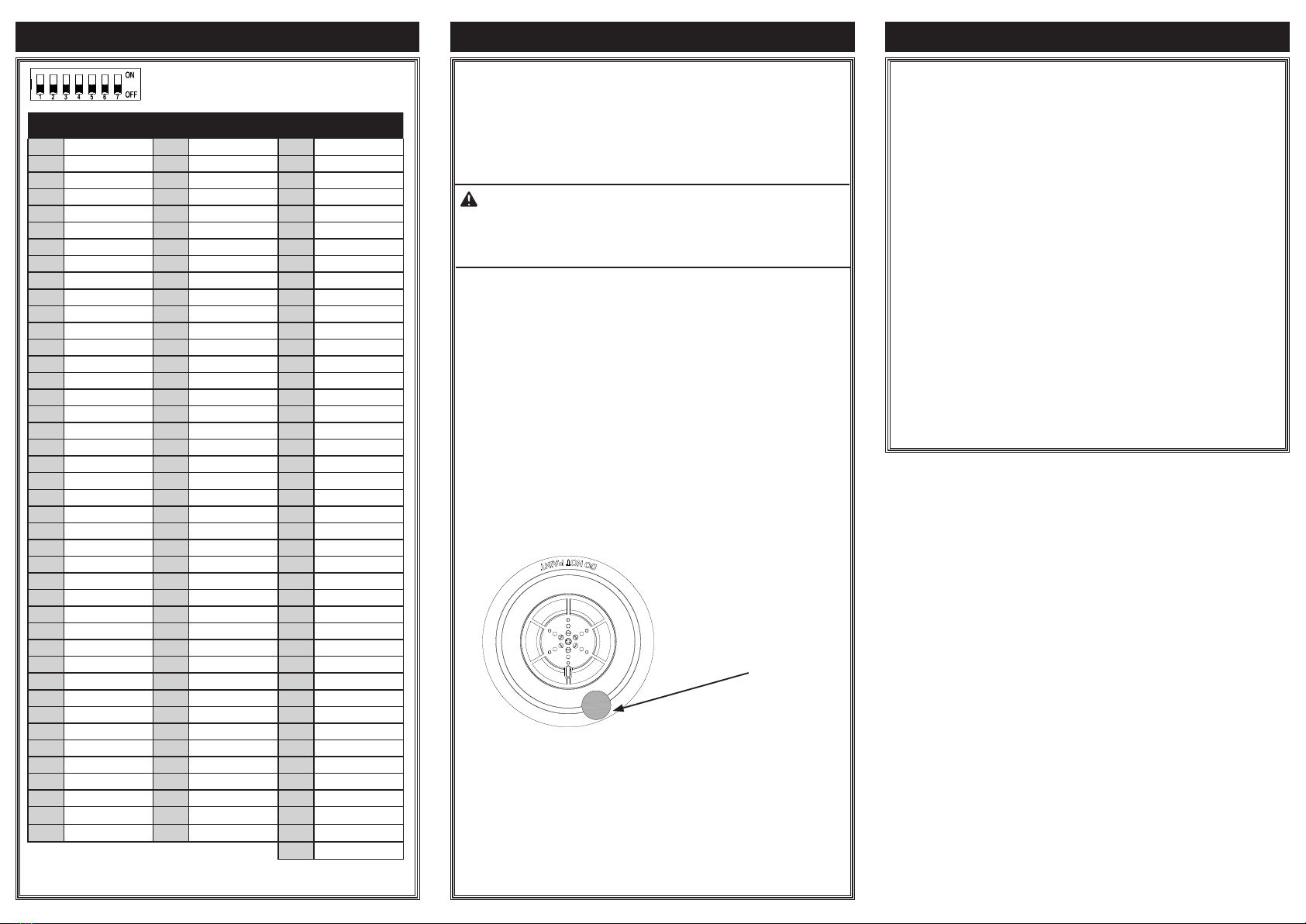

Magnet Test

e magnet test provides a quick test to verify the connections

and the detector electronically. is test should not replace the

aerosol test, which is required as part of regular testing and

maintenance per NFPA 72.

1. Hold the test magnet in the magnet test area as shown

below.

2. e LED ashes rapidly to indicate the detector is in

alarm.

3. Remove magnet.

4. Alarm on the re alarm panel should be reset.

5. Unit failed the magnet test should be tested again

with heat gun or hair dryer to conrm the failure.

F. Testing

NOTIFY APPROPRIATE AUTHORITY BEFORE

TESTING THE DETECTOR. PLACE FIRE PANEL IN

WALK TEST

MODE BEFORE CONDUCTING THE FOLLOWING TEST. REFER

TO THE PANEL INSTALLATION MANUAL FOR DETAIL.

Magnet Location

POTTER warrants that the equipment herein shall conform

to said descriptions as to all armation of fact and shall be

free from defects of manufacture, labeling, and packaging for

a period of ve (5) years from the invoice date to the original

purchaser, provided that representative samples are returned

to POTTER for inspection. e product warranty period is

stated on the exterior of the product package. Upon a de-

termination by POTTER that a product is not as warranted,

POTTER shall, at its exclusive option, replace or repair said

defective product or parts thereof at its own expense, except

that Purchaser shall pay all shipping, insurance, and similar

charges incurred in connection with the replacement of the

defective product or parts thereof. is Warranty is void in

the case of abuse, misuse, abnormal usage, faulty installation,

or repair by unauthorized persons, or if for any other reason

POTTER determines that said product is not operating prop-

erly as a result of causes other than defective manufacture,

labeling, or packaging.

G. Warranty

Manual Number:

54035210X_A

Manual Issue Date:

07/01/2022