Faults

Should a fault occur, e.g. after wear of a part, please

contact your local Ferm dealer.

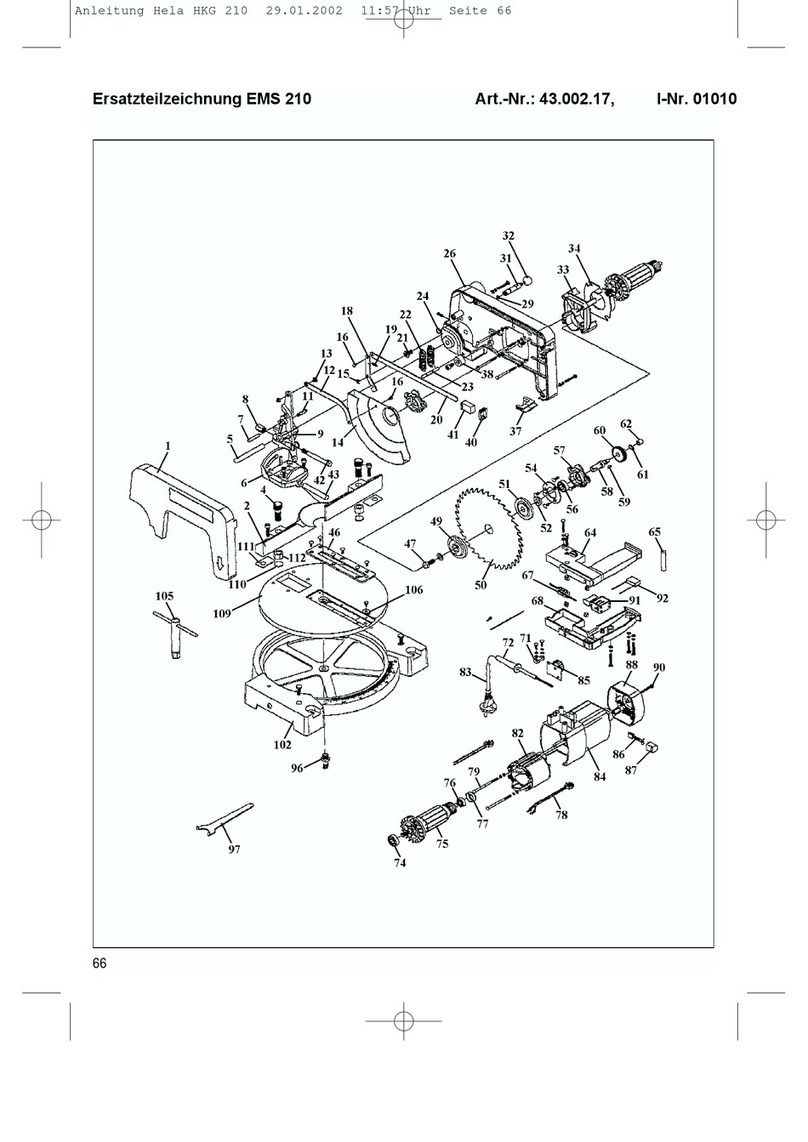

In the back of this manual you find an exploded view

showing the parts that can be ordered.

ENVIRONMENT

In order to prevent the machine from damage during

transport, it is delivered in a sturdy packaging. Most of

the packaging materials can be recycled. Take these

materials to the appropriate recycling locations.

Take your unwanted machines to your local Ferm-

dealer. Here they will be disposed of in an

environmentally safe way.

GUARANTEE

The guarantee conditions can be found on the separately

enclosed guarantee card.

We declare under our sole responsibility that this

product is in conformity with the following standards or

standardized documents

EN 50144-1, EN 50144-2-3, EN 55014-1,

EN 55014-2,EN 61000-3-2, EN 61000-3-3

in accordance with the regulations.

98/37/CEE,

73/23/CEE,

93/68/CEE,

89/336/CEE

from 01-05-2004

Oststrasse 11 - 13

50996 KÖLN BRD

E. Kok

Quality department

CE

ı

DECLARATION OF CONFORMITY (UK)

Powercraft 5

9. Use safety glasses.

Also use face or dust mask when operation is dusty.

10.Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11.Do not abuse cord.

Never carry tool by cord or yank it to disconnect it

from electrical socket. Keep cord from heat, oil and

sharp edges.

12.Secure work.

Use clamps or a vice to hold work. It’s safer than

using your hand and it frees both hands to operate

tool.

13.Do not overreach.

Keep proper footing and balance at all times.

14.Maintain tools with care.

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically

and, if damaged, have repaired by authorized service

facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and free

from oil and grease.

15.Disconnect tools.

When not in use, before servicing and when changing

accessories such as blades, bits and cutters.

16.Remove adjusting keys and wrenches.

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17.Avoid unintentional starting.

Do not carry plugged-in tools with finger on switch.

Be sure switch is off when plugging in.

18.Outdoor use extension cords.

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

Always use tool in conjunction with a residual circuit

breaker device.

19.Stay alert.

Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

20.Check damaged parts.

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

determine that it will operate properly and perform

its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged

should be properly repaired or replaced by an

authorized service centre unless otherwise indicated

elsewhere in this instructions manual. Have defective

switches replaced by an authorized centre. Do not

use tool if switch does not turn on and off.

21.Warning.

The use of any other accessory or attachment other

than recommended in this operation instructions or

the catalogue may present a risk of personal injury.

22.Have your tool repaired by an expert.

This appliance is manufactured to very high

standards and meets relevant safety regulations.

Repairs should only be done by a suitable qualified

electrical engineer or otherwise.

23.Hear protection must be worn.

USE

FITTING A SAW BLADE

The machine is equipped with a quick fit system.

•Turn the clamping ring of the saw blade holder as far

to the left as possible and hold it there.

• Place the saw blade in the blade holder.

• Let go of the clamping ring.

•Make sure when changing the saw blade that the

blade holder is free of material debris (such as

splinters of wood or metal).

•Before use, always check that the saw blade is

securely fixed.

Removing the saw blade

•Turn the clamping ring of the saw blade holder as far

to the left as possible and hold it there.

•Remove the saw blade from its holder.

• Let go of the clamping ring.

ADJUSTMENT OF THE GUIDE SHOE

Fig. 1

In order to be able to follow the shoe guide (6) easily, and

to make it rest properly on the material to be sawn, you

can adjust the guide shoe. This can be done by releasing

the handle (4) under the machine at the front and then

moving the guide shoe forwards or backwards.

Make sure that the guide shoe handle is returned to the

closed position before you begin to use the machine

again.

USING THE SAW

Fig. 3

Press the switch (1) to start the motor.

To make the saw run continuously, press switch (1) and

then press the button on the side of the handgrip (3).

To switch off continuous running, press switch (1) and

release it again.

The small blade with fine teeth that is supplied (Fig. 1,

no.8) can be used for sawing non-ferrous metals (max

3mm) such as aluminium or copper.

Never put force on the saw blade when you are sawing.

MAINTENANCE

During maintenance and cleaning always remove

the mains plug from the socket. Never use liquids

when cleaning electrical parts of the saw bench.

Cleaning

Keep the ventilation slots of the machine clean to

prevent overheating of the engine. Regularly clean the

machine housing with a soft cloth, preferably after each

use. Keep the ventilation slots free from dust and dirt. If

the dirt does not come off use a soft cloth moistened

with soapy water. Never use solvents such as petrol,

alcohol, ammonia water, etc. These solvents may

damage the plastic parts.

Lubrication

The machine requires no additional lubrication.

4Powercraft