3. OPERATI G GUIDE

ALPHA C-20/25 CHARGER – OPERATI G MA UAL V1.0

Page 8

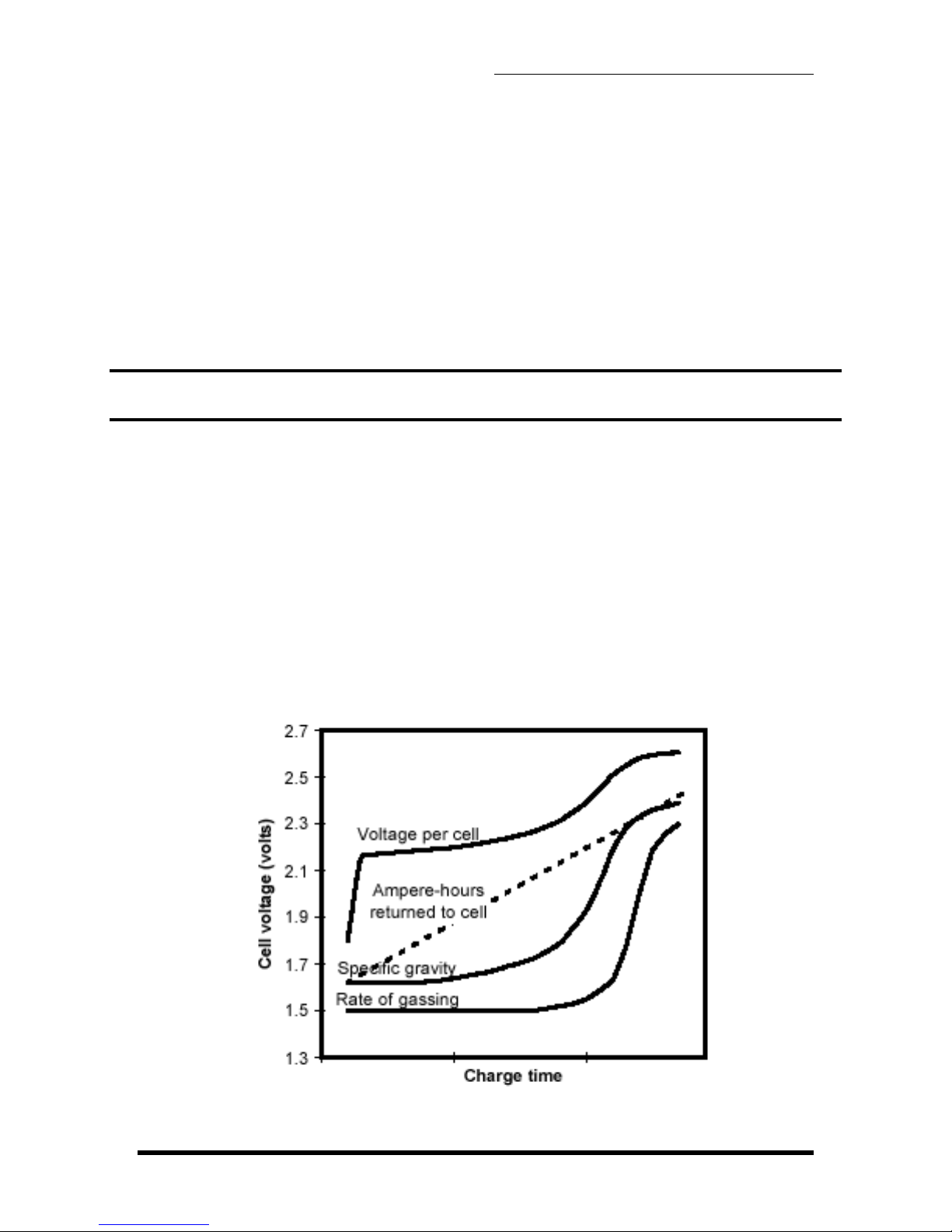

Figure 3-1. Charge characteristics of a lead-acid cell

As shown by the curve in figure 3-1 the cell voltage of a discharged battery rises

rapidly when the battery is first placed on charge. The extent of the initial rise

depends on the charging rate. As the charge continues, the voltage rises at a

slower rate and eventually levels off when a full state-of-charge is reached. It can

be seen that the specific gravity reading lags behind the rate of ampere-hour return

during most of the charging cycle. Consequently, the specific gravity is not

indicative of the available ampere-hour capacity until the cell approaches a full-

charge state.

When a battery reaches a full state-of-charge the voltage of the battery will

stabilize and remain constant or decrease. The charging should discontinue at this

stage. A minimum of 100% of previous discharge should be placed in the battery.

In general a vented battery may be charged at any rate that will not produce

excessive gassing or electrolyte temperatures above 115°F (46°C). Sealed lead-

acid batteries should never be charged in a constant-current mode with a current

greater than C

1

/10 (C

1

equals the rated capacity of the battery). During constant

current charging at a rate in excess of C

1

/10, oxygen is produced at an excessive

rate. The resulting increasing pressure will cause the cell to vent. Venting of

gasses results in a depletion of electrolyte. As the electrolyte cannot be replaced in

a sealed battery, the cell will dry out resulting in a decrease in capacity and

eventually battery failure. Therefore constant-potential charging is the

recommended charge method for sealed batteries (SLAB).

3.2 CHARGING METHODS

There are two main methods of charging a battery:

1) constant current

2) constant potential.

In what follows both methods will be described in some detail.

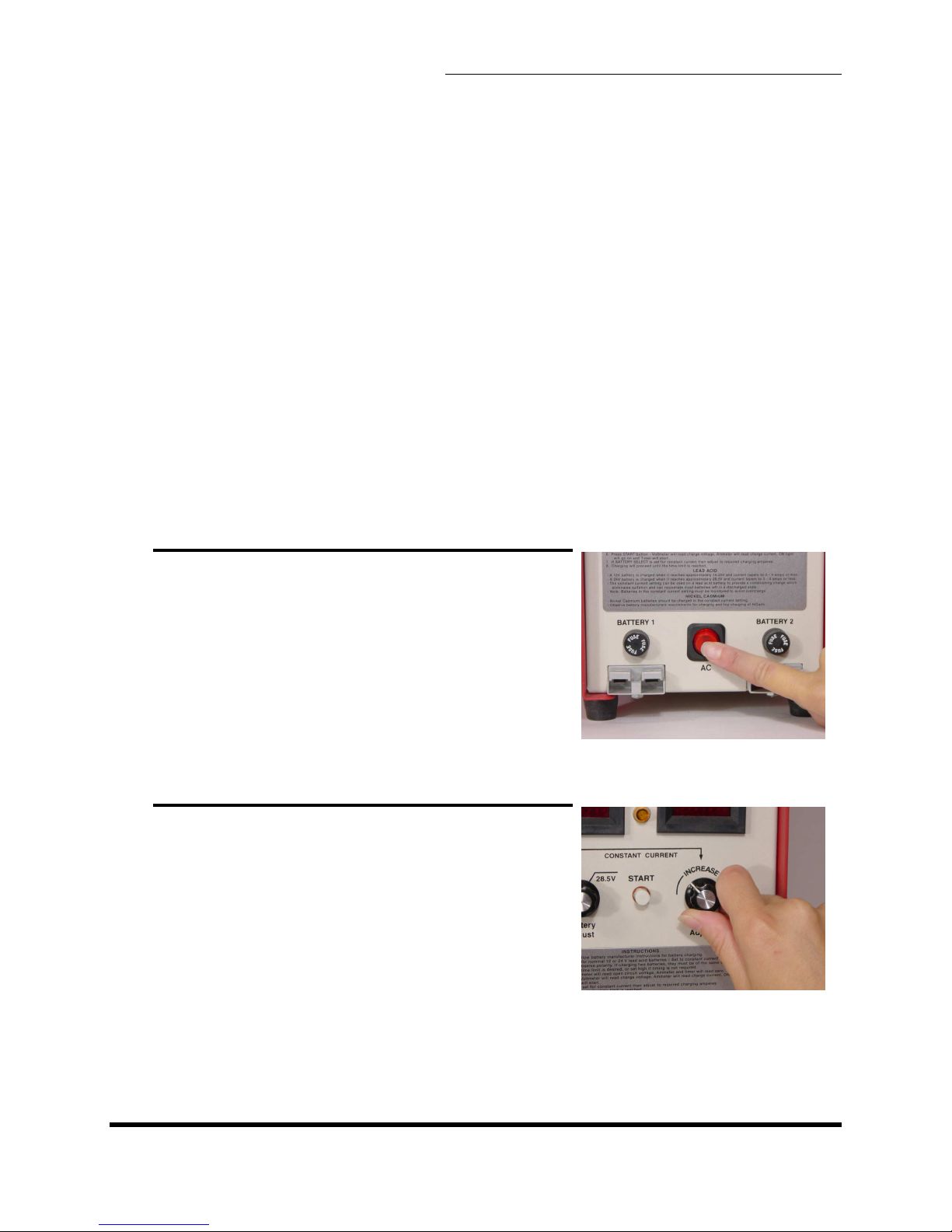

3.2.1 CONSTANT-CURRENT CHARGE METHOD

In this method the current remains at a preset level while the voltage can reach a

high level, e.g. 34-37 volts.

An advantage of the constant-current charge method is that the ampere-hour input

into the battery can be determined precisely by multiplying the charging current

with the charge time in hours. However, it is necessary to ensure that the battery is

not charged at a high rate for an excessive period of time. Such overcharging can

result in overheating, excessive gassing, and possible damage to the battery.