SECTION 1

INTRODUCTION AND DESCRIPTION

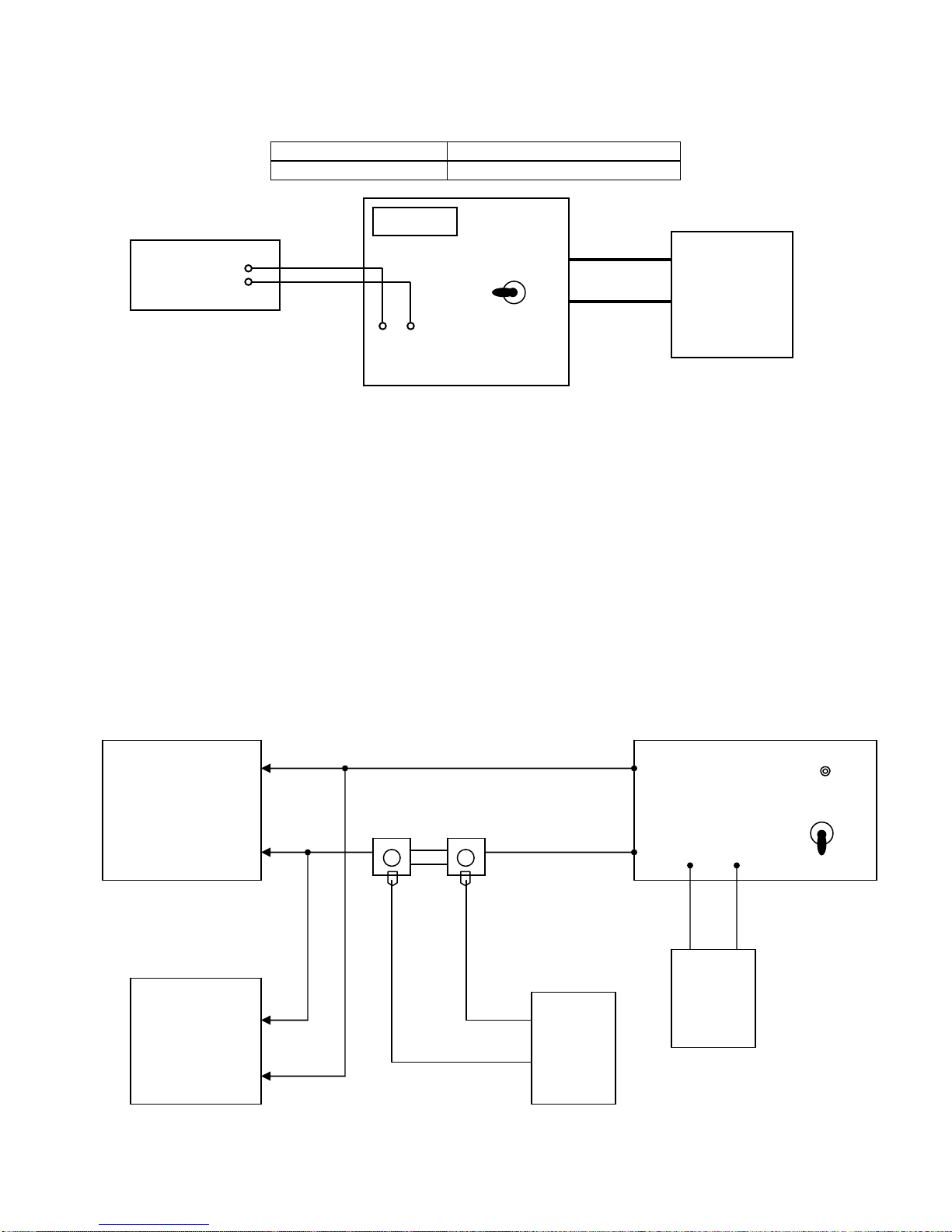

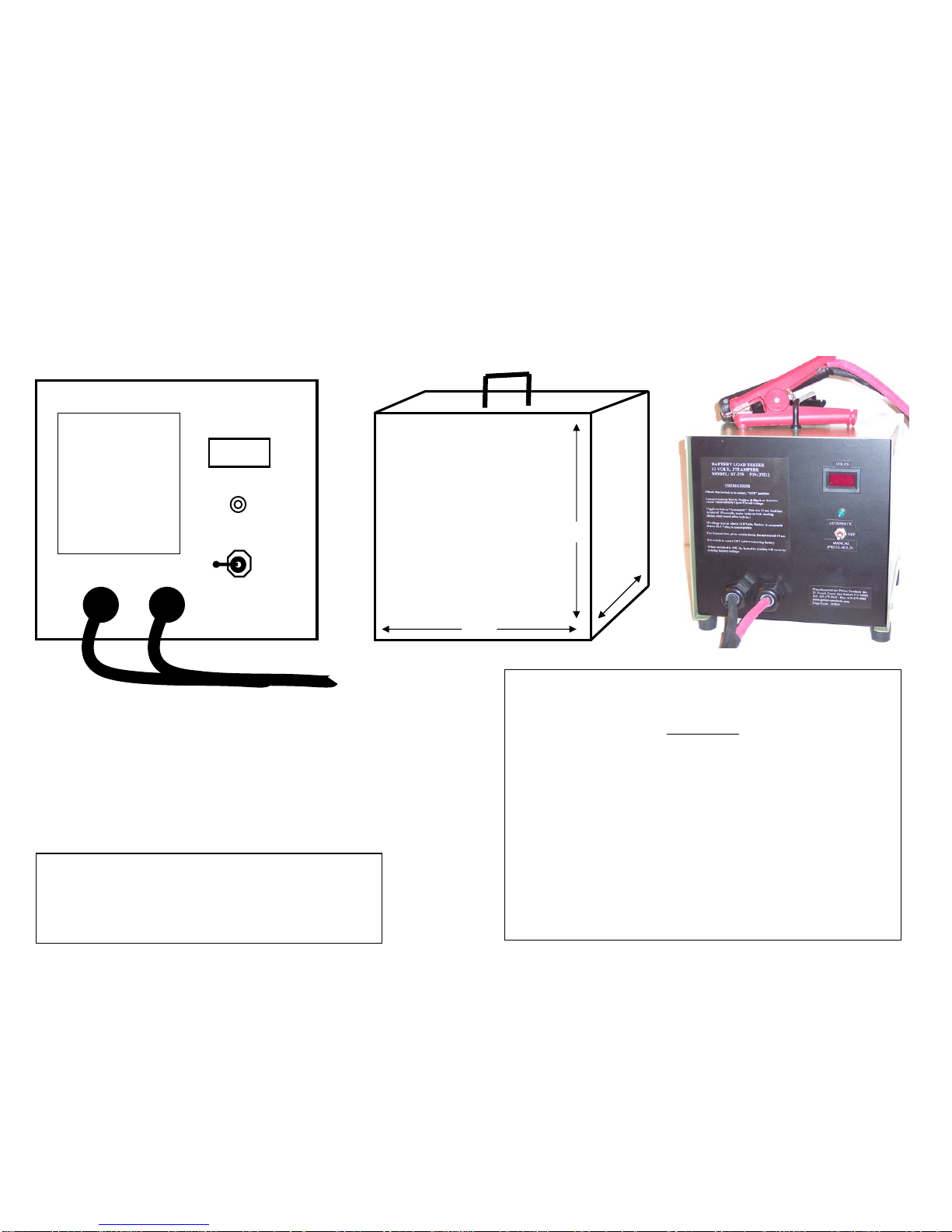

1.1 The ST-375 (P/N 37512) High Rate Discharge Unit is For testing SLI (Starting, Lighting, Ignition) engine start

batteries. It is used to accept or reject reject 12-Volt engine start batteries which have been fully charged prior to

testing. The ST-375 is designed to work on batteries that have CCA (Cold Cranking Amps) ratings in the

approximate range of 700 CCA to 1,000 CCA. However it will also accurately test batteries with a higher CCA

rating such as those used in large commercial trucks and military tactical vehicles. The unit is essentially an

SAE (Society of Automotive Engineers) tester which places a 375 Ampere load on the battery for a period of 15

seconds. A digital voltmeter on the unit reads and holds the battery voltage at the end of 15 seconds. If the

voltage is at or above 10.0 volts, the battery is ready for issue. If the voltage is below 10.0 volts the battery is

rejected. The battery may be recharged for another test depending on circumstances such as if this were a first

attempt to condition the rejected battery. The ST-375 has a high wattage resistive load bank. The resistors do

not glow during the 15 second test. The control switch has an automatic position which is pressed, released, and

tests for 15 seconds. A manual position can be pressed for less then 15 seconds. An internal 500 Ampere Shunt

has its test terminals (Kelvin Terminals) connected to a pair of test points on the front panel. The voltmeter also

has test points.

1.2 This procedure describes the verification of accuracy of Power Products High rate Discharger Tester P/N

37512. The 37512 being verified is referred to herein as the TI (Test Instrument). The TI operates from the

battery being tested and does not require any other power.

1.3 This procedure includes tests of essential performance parameters only. Any malfunction or out of limit

readings noticed during these procedures, whether specifically tested for or not, should be referred to power

products.

Table 1. Verification Description

TI Characteristics Performance Specification Test Method

Voltmeter

Internal shunt and load current

(NOTE: Shunt is 500Amp.

50 Millivolt)

2 internal timers. Timer 1

holds the voltmeter reading at

the end of 15 second test.

Timer 2 disconnects load 3

seconds after voltage hold (18

seconds total)

Range: 0 to 13 V (Meter range 99.9 V)

Tolerance: 0.2 V

Range: 0 to 38MV/380Amp

Tolerance: 1.0 Millivolts/ 10 Amps

Actual load tolerance is 375 Amps ± 10

Amps at 10.5 Volts 10 Seconds of load

(.028 Ohms at 10 Seconds)

TIME: tolerance 2 Seconds

TIME: tolerance 2 Seconds

Connect to battery or power supply, keep

TI power switch OFF. Compare TI

voltmeter reading with multi-meter.

Load the TI with a battery or high current

12 volt power supply. Use external shunt

and 2 multi-meters. Compare TI reading

with one multi-meter and with external

shunt and second multi-meter.

NOTE: Amp reading is 10X millivolt

reading

Check with Quartz stop-watch or timer.

Check with Quartz stop-watch or timer.

1