PR 9100 Series User manual

9113

Temperature /

mA Converter

No. 9113V106-UK

Product version: 9113-004

1503

PR electronics A/S tilbyder et bredt program af analoge og digitale

signalbehandlingsmoduler til industriel automation. Programmet

består af Isolatorer, Displays, Ex-barrierer, Temperaturtransmittere,

Universaltransmittere mfl. Vi har modulerne, du kan stole på i selv

barske miljøer med elektrisk støj, vibrationer og temperaturudsving,

og alle produkter opfylder de strengeste internationale standarder.

Vores motto »Signals the Best« er indbegrebet af denne filosofi – og

din garanti for kvalitet.

PR electronics A/S oers a wide range of analog and digital

signal conditioning devices for industrial automation. The product

range includes Isolators, Displays, I.S. Interfaces, Temperature

Transmitters, and Universal Devices. You can trust our products in

the most extreme environments with electrical noise, vibrations and

temperature fluctuations, and all products comply with the most

exacting international standards. »Signals the Best« is the epitome

of our philosophy – and your guarantee for quality.

PR electronics A/S ore une large gamme de produits pour le

traitement des signaux analogiques et numériques dans tous

les domaines industriels. La gamme de produits s’étend des

transmetteurs de température aux acheurs, des isolateurs aux

interfaces SI, jusqu’aux modules universels. Vous pouvez compter

sur nos produits même dans les conditions d’utilisation sévères,

p.ex. bruit électrique, vibrations et fluctuations de température.

Tous nos produits sont conformes aux normes internationales les

plus strictes. Notre devise »SIGNALS the BEST« c’est notre ligne

de conduite - et pour vous l’assurance de la meilleure qualité.

PR electronics A/S verfügt über ein breites Produktprogramm

an analogen und digitalen Signalverarbeitungsgeräte für die in-

dustrielle Automatisierung. Dieses Programm umfasst Displays,

Temperaturtransmitter, Ex- und galvanische Signaltrenner, und

Universalgeräte. Sie können unsere Geräte auch unter extremen

Einsatzbedingungen wie elektrisches Rauschen, Erschütterungen

und Temperaturschwingungen vertrauen, und alle Produkte von

PR electronics werden in Übereinstimmung mit den strengsten

internationalen Normen produziert. »Signals the Best« ist Ihre

Garantie für Qualität!

DK

UK

FR

DE

9113 - Product Version 9113-004 1

TEMPERATURE / mA CONVERTER

9113

CONTENTS

Warning....................................................................................................... 2

Symbol identification............................................................................ 2

Safety instructions................................................................................. 2

How to demount system 9000 ........................................................ 4

Advanced features................................................................................. 5

Application................................................................................................. 5

Technical characteristics...................................................................... 5

Applications............................................................................................... 6

PR 4501 display / programming front........................................... 7

Mounting / demounting the PR 4501/4511............................... 8

Ordering codes for 9113B................................................................... 9

Accessories ............................................................................................... 9

Electrical specifications........................................................................ 9

Configuration of sensor error check................................................ 14

Input signal outside range.............................................................. 14

Sensor error detection...................................................................... 14

Error indications................................................................................... 14

Connections .............................................................................................. 16

Block diagram........................................................................................... 17

Signal error and cable fault indications

without display front......................................................................... 18

Configuration / operating the function keys............................... 19

Routing diagram...................................................................................... 22

Routing diagram, Advanced settings (ADV.SET)........................ 24

Scrolling help texts in display line 3............................................... 25

Appendix.................................................................................................... 26

IECEx Installation Drawing.............................................................. 27

ATEX Installation Drawing............................................................... 30

FM Installation Drawing ................................................................... 33

INMETRO Installation Drawing ...................................................... 36

Safety Manual....................................................................................... 39

2 9113 - Product Version 9113-004

SYMBOL IDENTIFICATION

Triangle with an exclamation mark: Read the manual before installation

and commissioning of the device in order to avoid incidents that could lead

to personal injury or mechanical damage.

The CE mark proves the compliance of the device with the essential

requirements of the directives.

The double insulation symbol shows that the device is protected by

double or reinforced insulation.

Ex devices have been approved according to the ATEX directive for use in

connection with installations in explosive areas.

SAFETY INSTRUCTIONS

DEFINITIONS

Hazardous voltages have been defined as the ranges: 75...1500 Volt DC, and

50...1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and also

troubleshoot technically correct and in accordance with safety regulations.

Operators, being familiar with the contents of this manual, adjust and operate

the knobs or potentiometers during normal operation.

WARNING

The following operations should only be carried out on a discon-

nected device and under ESD-safe conditions:

General mounting, connection and disconnection of wires.

Troubleshooting the device.

Repair of the device and replacement of circuit breakers must

be done by PR electronics A/S only.

WARNING

Do not open the front plate of the device as this will cause dama-

ge to the connector for the display / programming front PR 4501.

This device contains no DIP-switches or jumpers.

9113 - Product Version 9113-004 3

RECEIPT AND UNPACKING

Unpack the device without damaging it. The packing should always follow the

device until this has been permanently mounted.

Check at the receipt of the device whether the type corresponds to the one

ordered.

ENVIRONMENT

Avoid direct sunlight, dust, high temperatures, mechanical vibrations and shock,

as well as rain and heavy moisture. If necessary, heating in excess of the stated

limits for ambient temperatures should be avoided by way of ventilation.

The device must be installed in pollution degree 2 or better.

The device is designed to be safe at least under an altitude up to 2 000 m.

MOUNTING

Only technicians who are familiar with the technical terms, warnings, and instruc-

tions in the manual and who are able to follow these should connect the device.

Should there be any doubt as to the correct handling of the device, please contact

your local distributor or, alternatively,

PR electronics A/S

www.prelectronics.com

The use of stranded wires is not permitted for mains wiring except when wires

are fitted with cable ends.

Descriptions of input / output and supply connections are shown in the block

diagram and on the side label.

The device is provided with field wiring terminals and shall be supplied from

a Power Supply having double / reinforced insulation. A power switch shall be

easily accessible and close to the device. The power switch shall be marked as

the disconnecting device for the device.

For installation on Power Rail 9400 the power is supplied by Power Control

module 9410.

Year of manufacture can be taken from the first two digits in the serial number.

CALIBRATION AND ADJUSTMENT

During calibration and adjustment, the measuring and connection of external

voltages must be carried out according to the specifications of this manual. The

technician must use tools and instruments that are safe to use.

4 9113 - Product Version 9113-004

NORMAL OPERATION

Operators are only allowed to adjust and operate device that are safely fixed in

panels, etc., thus avoiding the danger of personal injury and damage. This means

there is no electrical shock hazard, and the device is easily accessible.

CLEANING

When disconnected, the device may be cleaned with a cloth moistened with

distilled water.

LIABILITY

To the extent the instructions in this manual are not strictly observed, the

customer cannot advance a demand against PR electronics A/S that would

otherwise exist according to the concluded sales agreement.

HOW TO DEMOUNT SYSTEM 9000

Picture 1:

By lifting the bottom lock, the device

is detached from the DIN rail.

9113 - Product Version 9113-004 5

TEMPERATURE / mA CONVERTER

9113

• Input for RTD, TC and mA

• Active / passive mA output

• 1 or 2 channels

• Can be supplied separately or installed on power

rail, PR type 9400

• SIL 2-certified via Full Assessment

Advanced features

• Configurationandmonitoringbywayofdetachabledisplayfront(PR4501);

process calibration and signal simulation.

• Copyingoftheconfigurationfromonedevicetoothersofthesametypevia

the display front.

• TCinputscanuseeithertheinternalCJCoraterminalwithabuilt-inPt100

sensor (PR 5910Ex, channel 1 / PR 5913Ex, channel 2) for higher accuracy.

• Thedeviceautomaticallydetectswhetheritmustsupplyanactiveorapassive

current signal.

• Advancedmonitoringofinternalcommunicationandstoreddata.

• SIL2functionalityisoptionalandmustbeactivatedinamenupoint.

Application

• Thedevicecanbemountedinthesafeareaandinzone2/cl.1div.2and

receive signals from zone 0, 1, 2 and zone 20, 21, 22 including M1 / Class I/II/

III, Div. 1, Gr. A-G.

• Conversionandscalingoftemperature(Pt,NiandTC)andactivecurrent

signals.

• The9113hasbeendesigned,developedandcertifiedforuseinSIL2

applications according to the requirements of IEC 61508.

Technical characteristics

• 1greenand2redfrontLEDsindicateoperationstatusandmalfunction.

• 2.6kVACgalvanicisolationbetweeninput,outputandsupply.

mA

mA

mA

mA

*

*

-

+

-

+

+

+

-

+

-

+

44

43

42

41

44

43

42

41

14

13

12

11

31

32

33

34

54

53

52

51

6 9113 - Product Version 9113-004

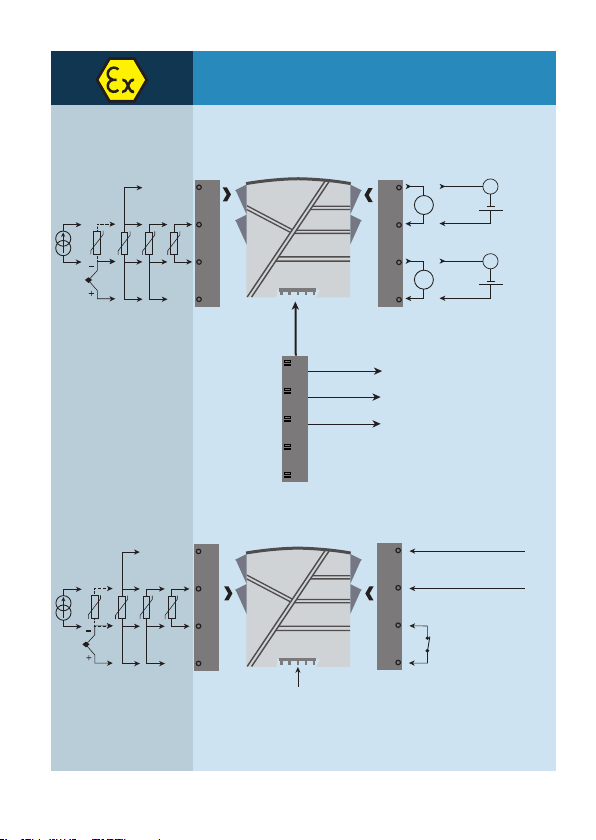

APPLICATIONS

Input signals:

Rail, +24 VDC

Rail, Gnd.

Power rail

Error signal

Analogue, 0/4...20 mA

Output signals:

Device status

Device status

Gnd.

Supply +19.2...31.2 VDC

N.C.

Power connection:

*Orderseparately:CJC

connetor 5910Ex/5913Ex

Zone 2 / Cl. 1, div. 2, gr. A-D or safe area

No connection

No connection

Channel 2:

Supply via

power rail

RTD

Connection,

wires

Current

TC

2-wire supply -

2-wire supply -

Ch. 1:

Ch. 2:

*Orderseparately:CJC

connetor 5910Ex/5913Ex

Zone 0, 1, 2,

20, 21, 22, M1 &

Cl. I/II/III, Div. 1

gr. A-G

Channel 1:

RTD

Connection,

wires

Current

TC

9113 - Product Version 9113-004 7

PR 4501 DISPLAY / PROGRAMMING FRONT

Functionality

The simple and easily understandable menu structure and the

explanatory help texts guide you effortlessly and automatically

through the configuration steps, thus making the product very

easy to use. Functions and configuration options are described

in the section ”Configuration / operating the function keys”.

Application

• Communicationsinterfaceformodificationofoperationalparametersin9113.

• Canbemovedfromone9113devicetoanotheranddownloadthe

configuration of the first unit to subsequent units.

• Whenmountedintheprocess,thedisplayshowsprocessvaluesanddevice

status.

Technical characteristics

• LCDdisplaywith4lines;Line1(H=5.57mm)showsinputstatus,line2and3

(H=3.33mm)showanalogueinput/outputvalueorTAGno.andunits,andline

4 shows status for communication and whether the device is SIL-locked. Static

dot=SIL-lockedandflashingdot=notSIL-locked.

• Programmingaccesscanbeblockedbyassigningapassword.Thepassword

is saved in the device in order to ensure a high degree of protection against

unauthorised modifications to the configuration.

OK

4501

1

3

4

2

3

8 9113 - Product Version 9113-004

MOUNTING / DEMOUNTING THE PR 4501/4511

1: Insert the taps of 4501/4511 into the holes at the top of the device.

2: Swing 4501/4511 into place.

Demounting of 4501/4511

3: Push the release button on the bottom of 4501/4511 and swing 4501/4511

up

Electrical specifications

Environmental conditions

Specifications range............................................... -20...+60°C

Storage temperature .............................................. -20...+85°C

Calibration temperature ........................................ 20...28°C

Relative humidity..................................................... < 95% RH (non-cond.)

Protection degree.................................................... IP20

Installation in............................................................. Pollution degree 2 & measurement /

overvoltage category II

Mechanical specifications:

Dimensions (HxWxD).............................................. 109 x 23.5 x 104 mm

Dimensions (HxWxD) w/ 4501 / 4511........... 109 x 23.5 x 116 / 131 mm

Weight approx........................................................... 250 g

Weight incl. 4501 / 4511 (approx.).................. 265 g / 350 g

DIN rail type............................................................... DIN EN 60715 / 35 mm

Wire size...................................................................... 0.13...2.08 mm2AWG 26...14

stranded wire

Screw terminal torque........................................... 0.5 Nm

Vibration...................................................................... IEC 60068-2-6 : 2007

Vibration: 2...13.2 Hz.............................................. ±1 mm

Vibration: 13.2...100 Hz........................................ ±0.7 g

Common specifications:

Supply voltage, DC.................................................. 19.2...31.2 VDC

Max. consumption.................................................... ≤3.5 W (2 channels)

4501 = Display / programming front

4511 = Communication enabler

5910Ex = CJC connector, channel 1

5913Ex = CJC connector, channel 2

9400 = Power rail

9404 = Module stop for rail

9410 = Power control unit

9420 = Power supply 24 V / 120 W - Ex nAC

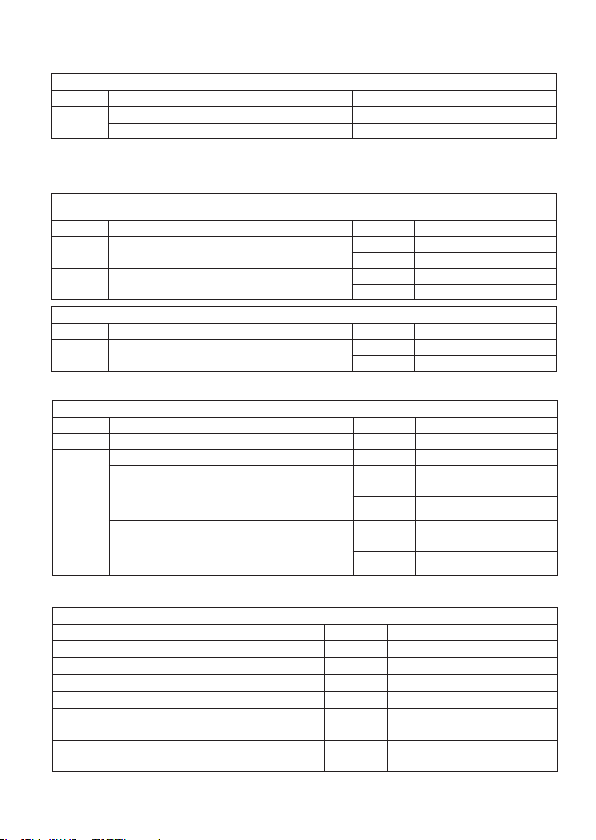

Ordering codes for 9113B

Type Channels

9113B Single : A

Double : B

Accessories

10 9113 - Product Version 9113-004

Fuse............................................................................... 400 mA SB / 250 VAC

Isolation - test / working:

Input to any...................................................... 2.6 kVAC / 300 VAC reinforced

Analogue output to supply........................ 2.6 kVAC / 300 VAC reinforced

Status relay to supply .................................. 1.5 kVAC / 150 VAC reinforced

Communications interface ................................... Communication enabler 4511 /

Programming front 4501

Signal / noise ratio .................................................. Min. 60 dB (0...100 kHz)

Average response time incl. delay:

Temperature input......................................... ≤1 s

mA input ............................................................ ≤0.4 s

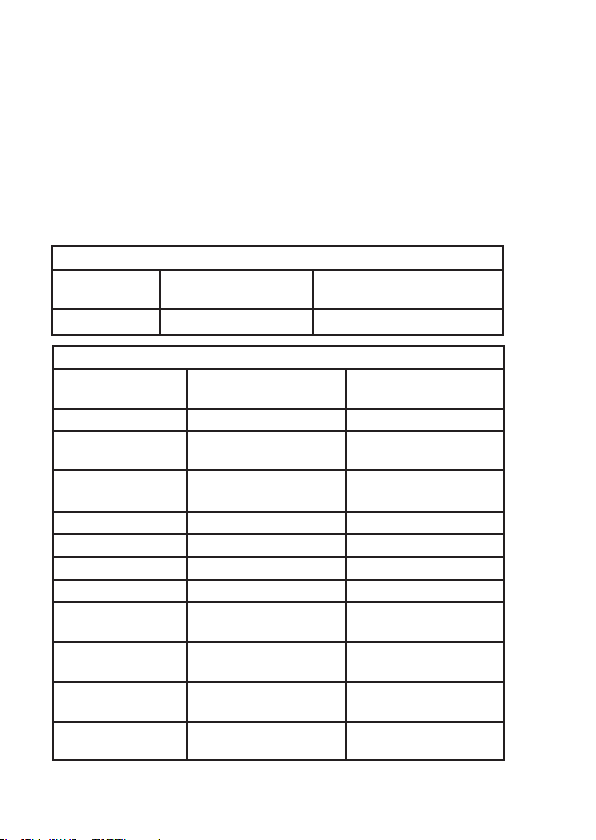

Accuracy, the greater of the general and basic values:

Basic values

Input

type Basic

accuracy Temperature

coefficient

mA ≤±16 µA ≤±1.6 µA / °C

Pt100, Pt200,

Pt 1000 ≤±0.2°C ≤±0.02°C / °C

Pt500, Ni100,

Ni120, Ni 1000 ≤±0.3°C ≤±0.03°C / °C

Pt50, Pt400, Ni50 ≤±0.4°C ≤±0.04°C / °C

Pt250, Pt300 ≤±0.6°C ≤±0.06°C / °C

Pt20 ≤±0.8°C ≤±0.08°C / °C

Pt10 ≤±1.4°C ≤±0.14°C / °C

TC type:

E,J,K,L,N,T,U

≤±1°C

≤±0.1°C / °C

TC type: R, S, W3,

W5, LR

≤±2°C

≤±0.2°C / °C

TC type: B

160...400°C ≤±4.5°C ≤±0.45°C / °C

TC type: B

400...1820°C ≤±2°C ≤±0.2°C / °C

General values

Input

type Absolute

accuracy Temperature

coefficient

All ≤±0.1% of span ≤±0.01% of span / °C

9113 - Product Version 9113-004 11

EMC immunity influence.................................................. < ±0.5% of span

Extended EMC immunity:

NAMUR NE 21, A criterion, burst ................................. < ±1% of span

RTD input:

Input for RTD types:

Pt10*, Pt20*, Pt50*, Pt100, Pt200, Pt250, Pt300, Pt400, Pt500, Pt1000

Ni50, Ni100, Ni120, Ni1000

Cable resistance per wire (max.)....................... 50 Ω

Sensor current........................................................... Nom. 0.2 mA

Effect of sensor cable resistance

(3- / 4-wire)................................................................ < 0.002 Ω/ Ω

Sensor error detection........................................... Programmable ON / OFF

Sensor error current:

when detecting............................................... < 2 μA

else......................................................... 0 μA

* No short circuit detection for Pt10, Pt20 and Pt50

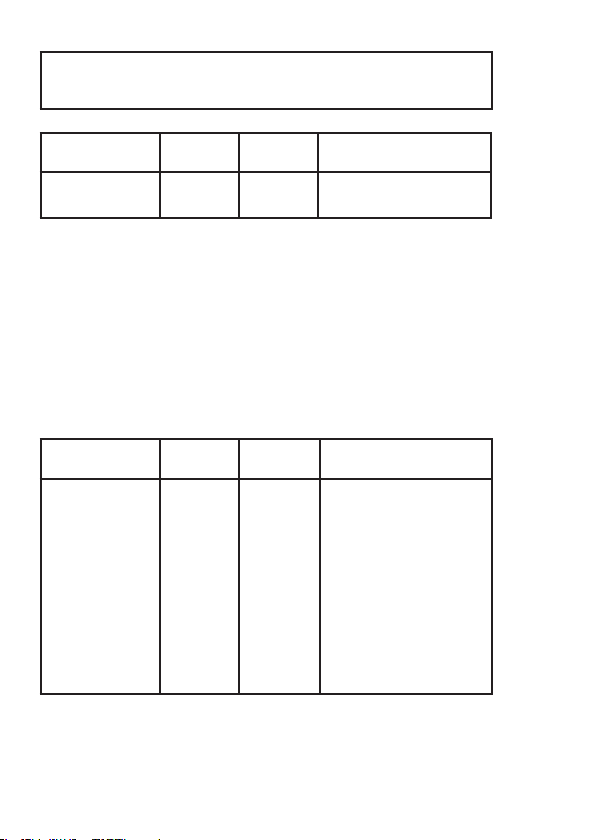

TC input:

Input

type Min.

value Max.

value

Standard

Pt100

Ni100 -200°C

-60°C +850°C

+250°C IEC60751

DIN 43760

Type Min.

value Max.

value

Standard

B

E

J

K

L

N

R

S

T

U

W3

W5

LR

+0°C

-100°C

-100°C

-180°C

-200°C

-180°C

-50°C

-50°C

-200°C

-200°C

0°C

0°C

-200°C

+1820°C

+1000°C

+1200°C

+1372°C

+900°C

+1300°C

+1760°C

+1760°C

+400°C

+600°C

+2300°C

+2300°C

+800°C

IEC 60584-1

IEC 60584-1

IEC 60584-1

IEC 60584-1

DIN 43710

IEC 60584-1

IEC 60584-1

IEC 60584-1

IEC 60584-1

DIN 43710

ASTM E988-90

ASTM E988-90

GOST 3044-84

12 9113 - Product Version 9113-004

Coldjunctioncompensation(CJC):

via external sensor in connector 5910. 20...28°C ≤±1°C

-20...20°C and 28...70°C ≤±2°C

viainternalCJCsensor.................................. ±(2.0°C + 0.4°C * ∆t)

∆t=internaltemperature-ambienttemperature

Sensor error detection........................................... Programmable ON or OFF

(only wire breakage)

Sensor error current:

when detecting............................................... Nom. 2 μA

else....................................................................... 0 μA

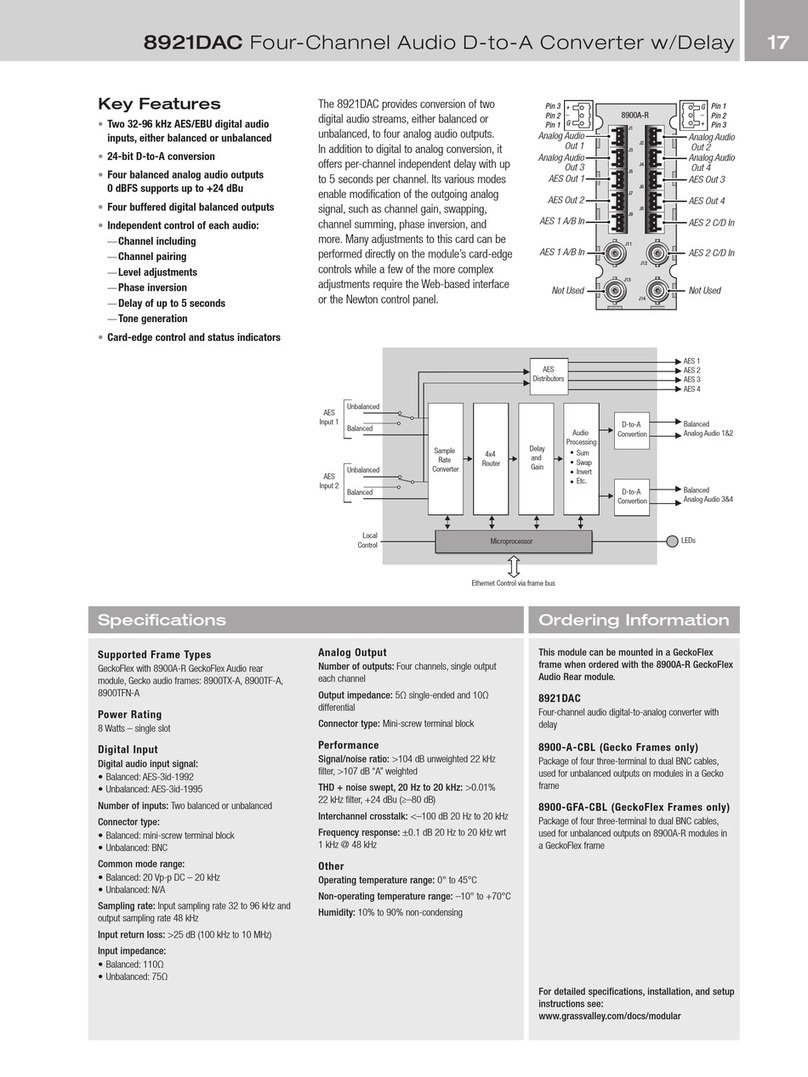

Current input:

Measurement range................................................ 0...20 mA

Programmable measurement ranges............... 0...20 and 4...20 mA

Input resistance........................................................ Nom. 20 Ω+ PTC 50 Ω

Sensor error detection........................................... Programmable ON / OFF

Only 4...20 mA (NAMUR)

Current output:

Signal range (span)................................................. 0...20 mA

Programmable signal ranges............................... 0...20 / 4...20 /

20...0 and 20...4 mA

Load (max.)................................................................. 20 mA / 600 Ω/ 12 VDC

Load stability............................................................. ≤0.01% of span / 100 Ω

Sensor error detection........................................... 0 / 3.5 / 23 mA / none

NAMUR NE 43 Upscale/Downscale................. 23 mA / 3.5 mA

Output limitation:

on 4...20 and 20...4 mA signals................ 3.8...20.5 mA

on 0...20 and 20...0 mA signals .............. 0...20.5 mA

Current limit ............................................................... ≤28 mA

2-wire 4...20 mA output:

Signal range............................................................... 4...20 mA

Load stability............................................................. ≤0.01% of span / 100 Ω

Load resistance......................................................... ≤(Vsupply -3.5)/0.023 A [Ω]

External 2-wire supply range ............................. 3.5...26 VDC

Effect of external 2-wire supply

voltage variation...................................................... < 0.005% of span / V

Status relay in safe area:

Max. voltage .............................................................. 125 VAC / 110 VDC

Max. current............................................................... 0.5 AAC / 0.3 ADC

Max. AC power .......................................................... 62.5 VA / 32 W

of span =ofthecurrentlyselectedmeasurementrange

9113 - Product Version 9113-004 13

Approvals:

EMC 2004/108/EC .................................................. EN 61326-1

LVD 2006/95/EC...................................................... EN 61010-1

c UL us, Standard for Safety................................ UL 61010-1

EAC TR-CU 020/2011............................................ EN 61326-1

Marine:

Det Norske Veritas, Ships & Offshore ............. Stand. f. Certific. No. 2.4

I.S. / Ex:

ATEX 94/9/EC............................................................ KEMA 07ATEX0148 X

IECEx............................................................................. IECEx KEM 09.0052X

c FM us......................................................................... 3038279-C

INMETRO ..................................................................... NCC 12.1310 X

CCOE.............................................................................. P337349/3

EAC Ex TR-CU 012/2011..................................... RU C-DK.GB08.V.00410

Functional Safety:

SIL2 Certified & Fully Assessed acc. to IEC 61508

14 9113 - Product Version 9113-004

Configuration of sensor error check

Visualisation in the 4501 of:

Input signal outside range

Sensor error detection

Error indications

Sensor error check:

Device: Configuration Sensor error detection:

9113 OUT.ERR=NONE. OFF

Else: ON

Outside range readout (IN.LO, IN.HI):

If the valid range of the A/D converter or the polynomal is exceeded

Input Range Readout Limit

CURR 0...20 mA / 4...20 mA IN.LO < -1.05 mA

IN.HI > 25.05 mA

TEMP TC / RTD IN.LO < temperature range -2°C

IN.HI > temperature range +2°C

Sensor error detection (SE.BR, SE.SH):

Input Range Readout Limit

CURR Loop break (4...20 mA) SE.BR <=3.6mA;>=20.75mA

TEMP

TC SE.BR > 10 kΩ...165 kΩ

RTD: 2-, 3- and 4-wire

For Pt10, Pt20, Pt50, Pt100, Pt200, Ni50 and

Ni120

SE.BR > 900...1000 Ω

(cable > 50 Ω)

SE.SH < app. 15 Ω

RTD: 2-, 3- and 4-wire

for Pt250, Pt300, Pt400, Pt500, Pt1000 and

Ni1000

SE.BR > 10...12 kΩ

(cable > 50 Ω)

SE.SH < app. 15 Ω

Display readout below min. / above max. (-1999, 9999):

Input Range Readout Limit

All All -1999 Display readout <-1999

9999 Display readout >9999

Readout at hardware error

Error search Readout Cause

Input underrange IN.LO See conditions above

Input overrange IN.HI See conditions above

Sensor wire breakage SE.BR See conditions above

Sensor short circuit SE.SH See conditions above

TestofinternalCJCsensor CJ.ER InternalCJCsensordefectorCJC

temperature out of range**

CJCconnectorerror-checkCJC-connectorblock CJ.CE DefectormissingCJC-connector,

temperature out of allowed range

9113 - Product Version 9113-004 15

! All error indications in the display flash once per second. The help text explains the error.

* Error is acknowledged by either stepping through the basic setup, or by resetting the device power.

Some types of errors can only be acknowledged by resetting the device power.

** Error is acknowledged by either stepping through the basic setup, or by resetting the device power.

Error can be disregarded by selecting input type different than TC.

*** Error is acknowledged by stepping through the basic setup.

Readout at hardware error

Error search Readout Cause

Input error - check input connection and reset power IN.ER

Signal levels on input beyond

limits or connected to wrong

terminals*

Output error - check output connections and reset power AO.ER Error in analogue output

current (SIL mode only)*

No communication NO.CO No communication with

(4501)

Flash memory error - check configuration FL.ER

CO.ER

FLASH error (configuration

invalid)***

Invalid configuration type or version TY.ER

Configuration read from

EEprom has invalid type or

rev. no.

Hardware error RA.ER RAM error*

Hardware error IF.ER Internal Flash error*

Hardware error SW.ER SW monitor error*

Hardware error AD.ER A/D converter error*

Hardware error AO.SU Analogue output supply error*

Hardware error CA.ER Factory calibration error*

Hardware error CM.ER Main CPU error*

Hardware error II.ER Initialisation check error*

Hardware error RS.ER Reset error*

Hardware error IC.ER Input communication error*

Hardware error M1.ER Main CPU to Ch.1 error*

Hardware error M2.ER Main CPU to Ch.2 error*

Hardware error MC.ER Main CPU config. error*

Hardware error MF.ER Main CPU Flash error*

Hardware error MR.ER Main CPU RAM error*

Hardware error MS.ER Main CPU supply error*

Hardware error MP.ER Main CPU ProgFlow error*

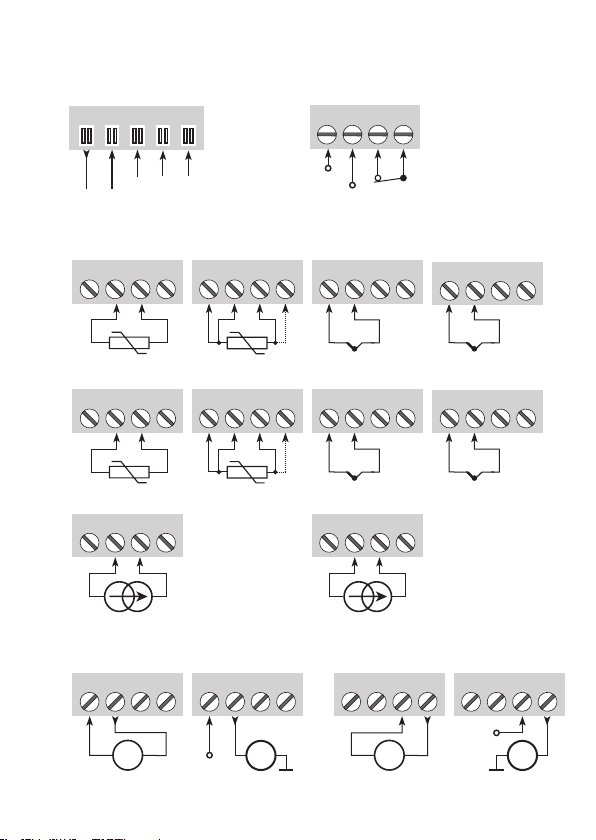

41 42 43 44 41 42 43 44 41 42 43 44 CJC

51 52 53 54 51 52 53 54 51 52 53 54

11 12 13 14

mA mA

11 12 13 14

41 42 43 44

mA

11 12 13 14

11 12 13 14

mA

51 52 53 54

31 32 33 34

CJC

51 5452

91 92 93 94 95

-+-+

-+ -+

-+ -+

-+

+

+

-+

4441 42

16 9113 - Product Version 9113-004

CONNECTIONS

Inputs

Outputs

Supply and

status relay

Current

(Active output

RTD, 3- / 4-wireRTD, 2-wire TC, internal

CJCsensor

Current

+24 V

N.C.

Gnd.

NCNCGnd.

+24 V

Power Rail

connections

2-wire transmitter

(Passive output)

Channel 1

RTD, 3- / 4-wireRTD, 2-wire

Channel 2Channel 1

Current

Channel 2

Channel 1

Current

(Active output 2-wire transmitter

(Passive output)

TC, internal

CJCsensor

*TC,

CJCconnector

* Order separately:

CJCconnector

5910Ex (ch. 1) /

5913Ex (ch. 2).

*TC,

CJCconnector

NC=noconnection

Error signal

9113

51

31

14

32

34

33

12

11

13

100C

12 mA

*

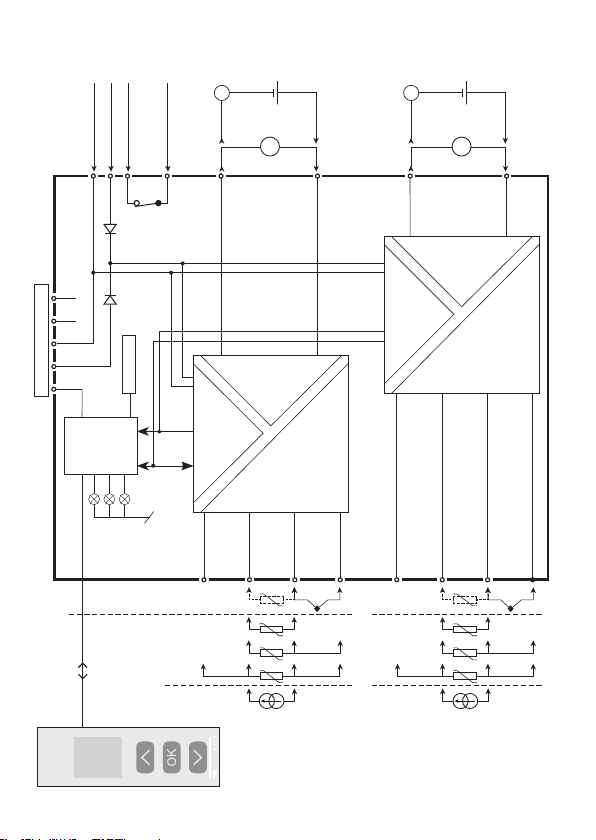

*

I+

mA

I+

mA

54

53

52

44

43

42

41

NC*NC*

+24V

CPU

FLASH

mA

mA

++

-

+

-

+

-

+

-

+

234

234

9113 - Product Version 9113-004 17

Status relay N.C.

Status relay N.C.

RTD, conn.

wires

Gnd.

Supply +24 VDC

Gnd.

Gnd.

Current

RTD, conn.

wires TC

Current

Gnd.

Power Rail connections

Channel 1

Channel 2

TC

Device status, Green

Ch. 1 status, Red

Ch. 2 status, Red

*NC=noconnection

BLOCK DIAGRAM

18 9113 - Product Version 9113-004

Signal error and cable fault indications without display front

List of LED and error signal indications

Condition Green LED Ch. 1:

Red LED

Ch. 2:

Red LED

Status relay,

N.C.

Power rail

signal status

Device OK Flashing OFF OFF Energized Open

No supply OFF OFF OFF De-energized Closed

Device defective OFF ON ON De-energized Closed

Ch. 1 defective (ch. 2 OK) Flashing ON OFF De-energized Closed

Ch. 2 defective (ch. 1 OK) Flashing OFF ON De-energized Closed

Channel 1, signal OK Flashing OFF OFF Energized Open

Ch. 1, wire short / break Flashing Flashing OFF De-energized Closed (if activated)

Channel 2, signal OK Flashing OFF OFF Energized Open

Ch. 2, wire short / break Flashing OFF Flashing De-energized Closed (if activated)

This manual suits for next models

3

Table of contents

Other PR Media Converter manuals