PR 9116 Series User manual

9116

Universal

converter

No. 9116V104-UK

Product version: 9116-003

1341

PR electronics A/S tilbyder et bredt program af analoge og digitale

signalbehandlingsmoduler til industriel automation. Programmet

består af Isolatorer, Displays, Ex-barrierer, Temperaturtransmittere,

Universaltransmittere mfl. Vi har modulerne, du kan stole på i selv

barske miljøer med elektrisk støj, vibrationer og temperaturudsving,

og alle produkter opfylder de strengeste internationale standarder.

Vores motto »Signals the Best« er indbegrebet af denne filosofi – og

din garanti for kvalitet.

PR electronics A/S oers a wide range of analogue and digital

signal conditioning devices for industrial automation. The product

range includes Isolators, Displays, Ex Interfaces, Temperature

Transmitters, and Universal Devices. You can trust our products in

the most extreme environments with electrical noise, vibrations and

temperature fluctuations, and all products comply with the most

exacting international standards. »Signals the Best« is the epitome

of our philosophy – and your guarantee for quality.

PR electronics A/S ore une large gamme de produits pour le

traitement des signaux analogiques et numériques dans tous

les domaines industriels. La gamme de produits s’étend des

transmetteurs de température aux acheurs, des isolateurs aux

interfaces SI, jusqu’aux modules universels. Vous pouvez compter

sur nos produits même dans les conditions d’utilisation sévères,

p.ex. bruit électrique, vibrations et fluctuations de température.

Tous nos produits sont conformes aux normes internationales les

plus strictes. Notre devise »SIGNALS the BEST« c’est notre ligne

de conduite - et pour vous l’assurance de la meilleure qualité.

PR electronics A/S verfügt über ein breites Produktprogramm an

analogen und digitalen Signalverarbeitungsmodule für die in-

dustrielle Automatisierung. Dieses Programm umfasst Displays,

Temperaturtransmitter, Ex- und galvanische Signaltrenner, und

Universalgeräte. Sie können unsere Geräte auch unter extremen

Einsatzbedingungen wie elektrisches Rauschen, Erschütterungen

und Temperaturschwingungen vertrauen, und alle Produkte von

PR electronics werden in Übereinstimmung mit den strengsten

internationalen Normen produziert. »Signals the Best« ist Ihre

Garantie für Qualität!

DK

UK

FR

DE

9116 - Product Version 9116-003 1

UNIVERSAL CONVERTER

9116

CONTENTS

Warning....................................................................................................... 2

Safety instructions................................................................................. 2

How to demount system 9000 ........................................................ 4

Advanced features................................................................................. 5

Application................................................................................................. 5

Technical characteristics...................................................................... 5

Applications............................................................................................... 6

PR 4501 Display / programming front........................................... 7

Ordering codes for 9116B .................................................................. 8

Accessories ............................................................................................... 8

Electrical specifications........................................................................ 8

Configuration of sensor error check................................................ 12

Input signal outside range.............................................................. 13

Sensor error detection...................................................................... 13

Hardware error..................................................................................... 14

Connections .............................................................................................. 16

Block diagram........................................................................................... 17

Signal error and cable fault indications

without display front......................................................................... 18

Configuration / operating the function keys............................... 19

Routing diagram...................................................................................... 24

Routing diagram, Advanced settings (ADV.SET)........................ 26

Scrolling help texts in display line 3............................................... 27

Graphic depiction of window ............................................................. 29

Graphic depiction of setpoint ............................................................ 30

Appendix.................................................................................................... 31

IECEx Installation Drawing.................................................................. 32

ATEX Installation Drawing .................................................................. 36

FM Installation Drawing....................................................................... 40

INMETRO Installation Drawing.......................................................... 44

Safety Manual .......................................................................................... 48

2 9116 - Product Version 9116-003

SYMBOL IDENTIFICATION

Triangle with an exclamation mark: Read the manual before installation

and commissioning of the device in order to avoid incidents that could lead

to personal injury or mechanical damage.

The CE mark proves the compliance of the device with the essential

requirements of the directives.

The double insulation symbol shows that the device is protected by

double or reinforced insulation.

Ex devices have been approved according to the ATEX directive for use in

connection with installations in explosive areas. See installation drawings

in appendix.

SAFETY INSTRUCTIONS

DEFINITIONS

Hazardous voltages have been defined as the ranges: 75...1500 Volt DC, and

50...1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and also

troubleshoot technically correct and in accordance with safety regulations.

Operators, being familiar with the contents of this manual, adjust and operate

the knobs or potentiometers during normal operation.

WARNING

The following operations should only be carried out on a discon-

nected device and under ESD-safe conditions:

General mounting, connection and disconnection of wires.

Troubleshooting the device.

Repair of the device and replacement of circuit breakers must

be done by PR electronics A/S only.

WARNING

Do not open the front plate of the device as this will cause dama-

ge to the connector for the display / programming front PR 4501.

This device contains no DIP-switches or jumpers.

9116 - Product Version 9116-003 3

RECEIPT AND UNPACKING

Unpack the device without damaging it and check whether the device type

corresponds to the one ordered. The packing should always follow the device

until this has been permanently mounted.

ENVIRONMENT

Avoid direct sunlight, dust, high temperatures, mechanical vibrations and shock,

as well as rain and heavy moisture. If necessary, heating in excess of the stated

limits for ambient temperatures should be avoided by way of ventilation.

The device must be installed in pollution degree 2 or better.

The device is designed to be safe at least under an altitude up to 2 000 m.

MOUNTING

Only technicians who are familiar with the technical terms, warnings, and instruc-

tions in the manual and who are able to follow these should connect the device.

Should there be any doubt as to the correct handling of the device, please contact

your local distributor or, alternatively,

PR electronics A/S

www.prelectronics.com

The use of stranded wires is not permitted for mains wiring except when wires

are fitted with cable ends.

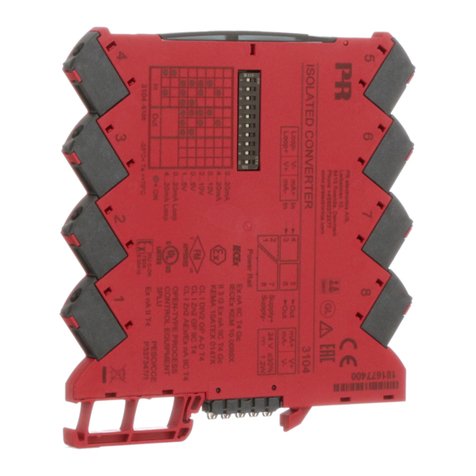

Descriptions of input / output and supply connections are shown in the block

diagram and on the side label.

The device is provided with field wiring terminals and shall be supplied from

a Power Supply having double / reinforced insulation. A power switch shall be

easily accessible and close to the device. The power switch shall be marked as

the disconnecting unit for the device.

For installation on Power Rail 9400 the power is supplied by Power Control Unit

9410.

Year of manufacture can be taken from the first two digits in the serial number.

CALIBRATION AND ADJUSTMENT

During calibration and adjustment, the measuring and connection of external

voltages must be carried out according to the specifications of this manual. The

technician must use tools and instruments that are safe to use.

Other manuals for 9116 Series

2

Table of contents

Other PR Media Converter manuals

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Linear Technology

Linear Technology DC1523A Demo Manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide