VF

5

3. SAFETY

3.1 General safety indications

The misuse of pumps and high pressure units, and the non-observance of installation and maintenance

instructions may cause severe injury to people and/or damage to property. Anyone requested to assemble or

use high pressure units must possess the necessary competence to do so, should be aware of the

characteristics of the components assembled/used, and must adopt all the necessary precautions in order to

guarantee maximum safety in any operating condition. In the interest of safety, no precaution that is

reasonably feasible must be neglected, both by the Manufacturer and the Operator.

3.2 High pressure unit safety requirements

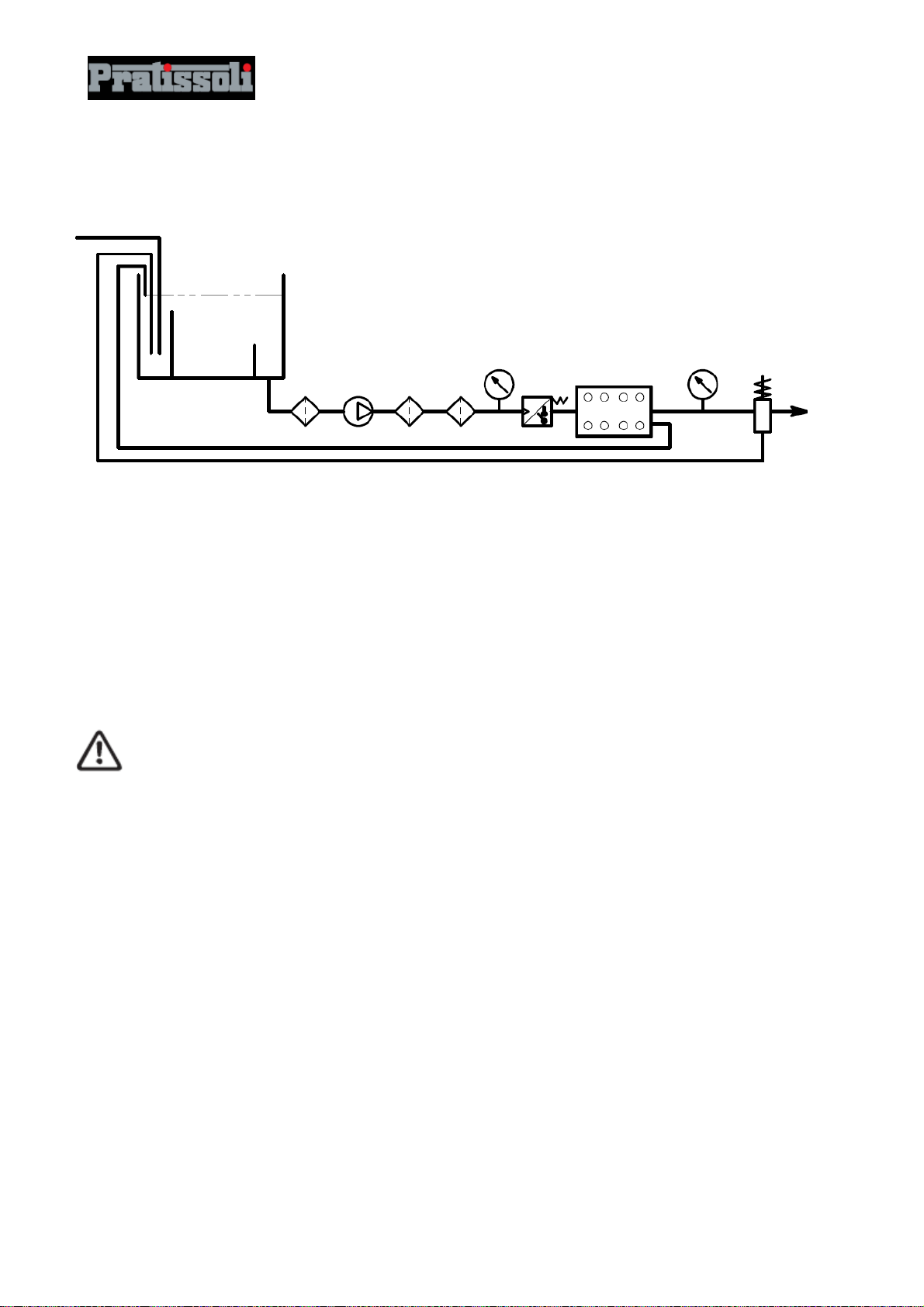

1. The pressure line must always be equipped with a safety valve.

2. High pressure unit components, in particular for those units working outside, must be adequately

protected against rain, frost and heat.

3. The unit’s electrical parts must be adequately protected from water spray, and must comply with the

specific norms in force.

4. High pressure pipes must be correctly sized for the unit’s maximum operating pressure, and must only be

used within the pressure range indicated by the pipe Manufacturer.

The same conditions apply for all other unit accessories where high pressure is involved.

5. The extremities of high pressure pipes must be sheathed and fastened to a steady structure in order to

avoid dangerous whiplashes should they burst or should their connections break.

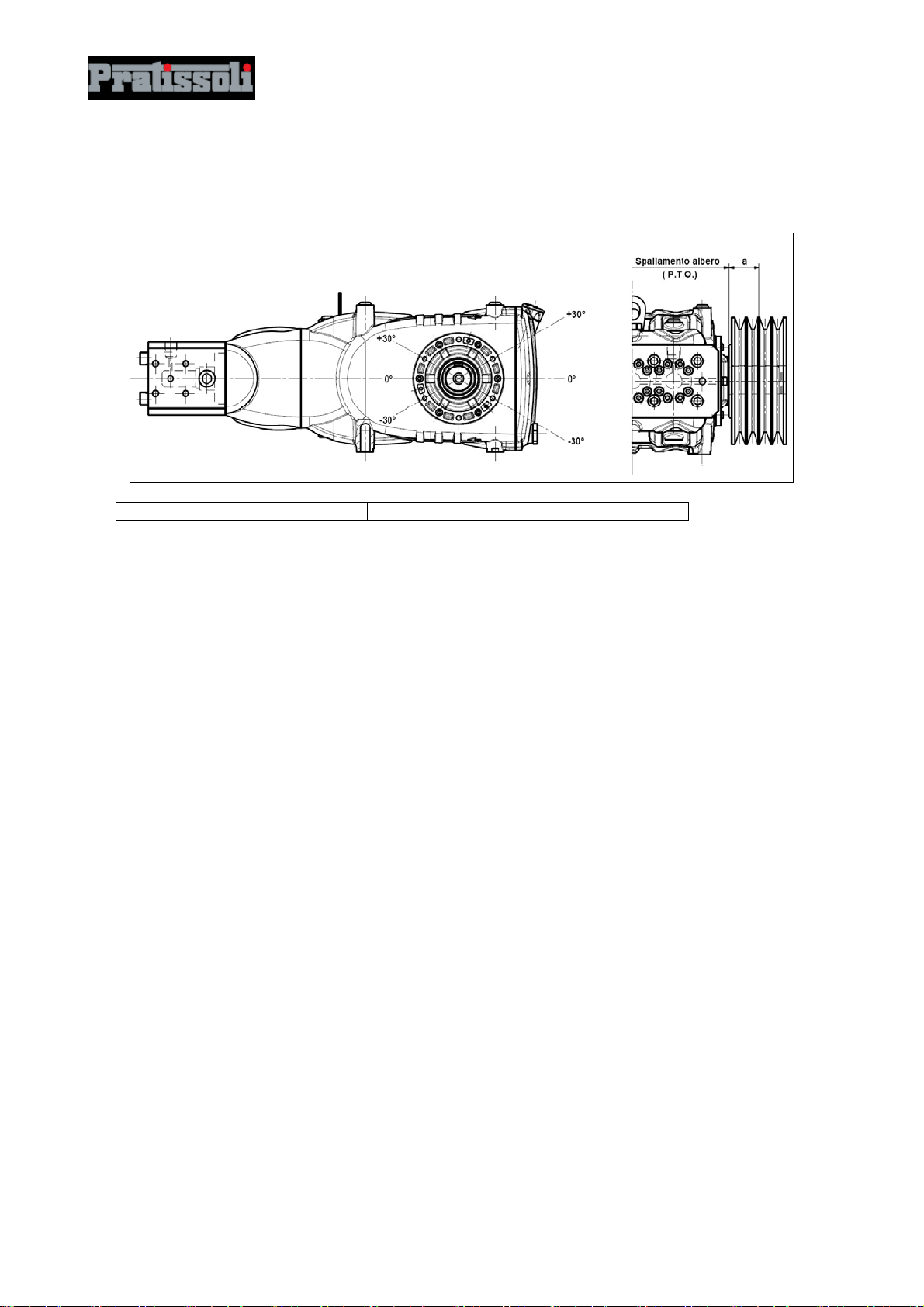

6. Appropriate safety guards must be provided for the pump transmission systems (joints, pulleys and belts,

auxiliary drives).

3.3 Safety during operation

The working area of a high pressure system must be clearly signalled. Access must be prohibited to non-

authorised personnel and, if possible, the area must be fenced in. The personnel authorised to access this

area must be previously trained, and informed about the risks that may arise from failures or malfunctions of

the high pressure unit.

Before starting the unit, the Operator must check:

1. That the high pressure unit is correctly fed (see paragraph 9.5).

2. That Pump intake filters are perfectly clean; we advise to use a device that indicates the filter’s clogging

level.

3. That electrical parts are adequately protected and in perfect conditions.

4. That high pressure pipes do not show apparent signs of abrasion, and that fittings are in perfect shape.

Any anomaly or reasonable doubt that may arise before or during operation must be promptly reported, and

verified by competent personnel. In these cases, pressure must be immediately released and the high

pressure unit stopped.

3.4 General procedures for using nozzles

1. The Operator must always place his own and other worker’s safety before any other interest; his actions

should always be governed by good sense and responsibility.

2. The Operator must always wear a helmet with a protective visor, waterproof clothing, and appropriate

boots capable of guaranteeing grip on wet pavements.

Note: appropriate clothing will effectively protect against water spray, but it may not offer adequate protection

against the direct impact of water jets or sprays from a close distance. Some circumstances may require

further protection.