www.predig.com

31/2DIGIT NEMA 4X LOOP-POWERED METER

PRECISION DIGITAL CORPORATION

CORPORATE HEADQUARTERS

19 Strathmore Road • Natick MA • 01760 • USA • Tel: (800) 343-1001 • Fax: (317) 216-1277

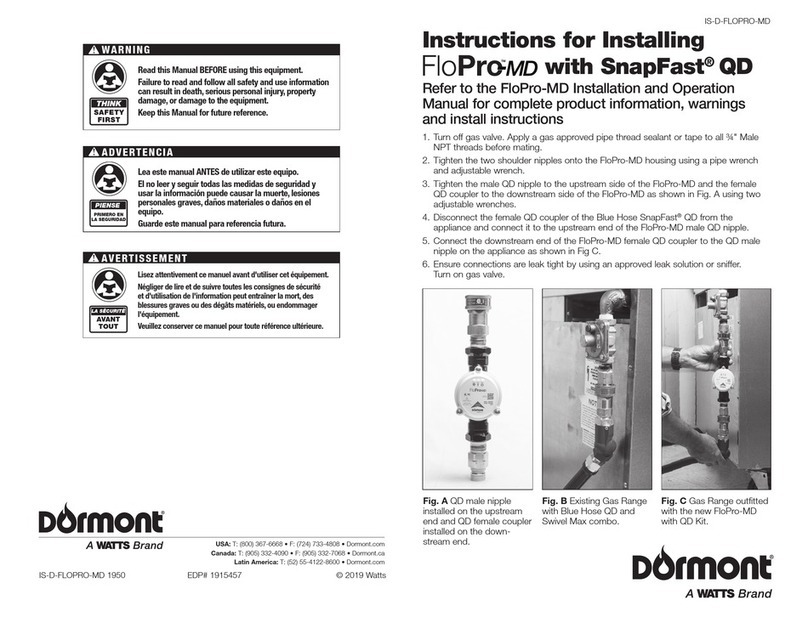

NOTE 1: If any of the following operations is performed in

the hazardous area, all appropriate hazardous area

procedures must be followed.

NOTE 2: To prevent damage to electronic components

caused by electrostatic discharge, a grounding strap should

be worn when servicing the display.

SETUP

The only tools needed for calibration are a calibrated current source and a

screwdriver.

CALIBRATION CONNECTIONS

To access the input terminals it is necessary to remove the enclosure cover

and the Display PCB. This is done by loosening the four screws on the

enclosure cover and removing the cover. Completely loosen the left screw

that holds the Display PCB to the enclosure and loosen the right screw

about four turns so the Display PCB remains secure to the enclosure.

Rotate the Display PCB 90° to gain access to the Input Signal PCB. Next,

connect a calibrated current source per Figure 1.

DECIMAL POINT SELECTION

The decimal point jumper array is located in the lower right corner of the

Display PCB next to the display. It is labeled DP1, DP2, DP3. Place a

jumper over both pins of DP1 for a display of 199.9, DP2 for 19.99, or

DP3 for 1.999.

CALIBRATION

LO and HI calibration controls are located to the left of the display

(see Figure 1). Apply a signal equal to 4 mA and adjust the LO control to

display the desired reading. Apply a signal between 16 and 20 mA and

adjust the HI control to display the desired reading. Complete the

calibration procedure by making any minor adjustments to the LO and HI

controls.

INSTALLATION

Installation of the meter involves removing the Display PCB from its

enclosure and connecting a 1/2″conduit fitting to the hole provided. Refer

to PD686 FM Approved & CSA Certified Loop-Powered Intrinsic Safety

Barrier Connections Diagrams for further details. Wall mounting holes are

located in each corner of the enclosure (see Figure 4).

LOOP CONNECTIONS

Disconnect power to the loop and install the meter as illustrated in Figure

2 and the PD686 FM Approved & CSA Certified Loop-Powered Intrinsic

Safety Barrier Connections Diagrams that are supplied with the instru-

ment. Replace the enclosure cover.

REMOVING THE DISPLAY PCB FROM ITS ENCLOSURE

Remove the enclosure cover and Display PCB as described in

“Calibration Connection” above. The Display PCB and Input Signal PCB

are connected together with one black and one red wire. The wires are

soldered to the Display PCB and connected to a screw terminal connector

on the Input Signal PCB. Disconnect the black and red signal wires from

the screw terminal connector and lift Display PCB from enclosure. Care

should be taken to avoid static electricity from damaging the electronic

circuitry.

REMOVING THE DISPLAY PCB FROM THE LOOP

Disconnect power to the loop prior to removing the Display PCB from its

enclosure. When removing the Display PCB care should be taken to avoid

static electricity damaging the electronic circuitry. Remove the enclosure

cover and Display PCB as described in the previous paragraph. To restore

the loop, connect LOOP JUMPER (see Figure 1) over both pins. Replace

cover and restore power to the loop. The loop will flow through LOOP

JUMPER. When the instrument is put back in service the push-on jumper

must be removed from LOOP JUMPER pins, save jumper by connecting

over one pin only.

SERVICING THE DISPLAY PCB OUTSIDE THE LOOP

Two modes of input signal allow the user to remove the Display PCB for

service without interrupting the loop as indicated above and operate the

Display PCB at another location. The loop remains connected to the Input

Signal PCB while the Display PCB is absent for service. The user may

operate the Display PCB at another location by connecting a signal to

“S+” & “S-” wires on the Display PCB.

Refer to Figure 3.

LIM686 Rev A 05/00