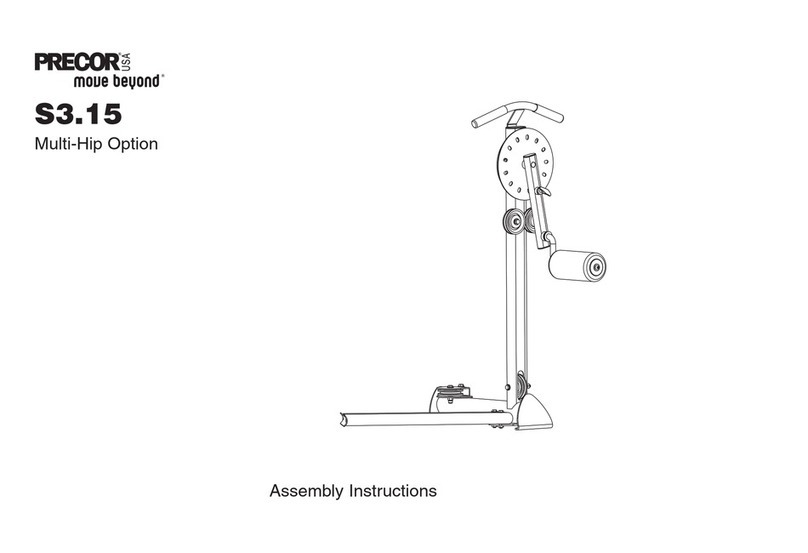

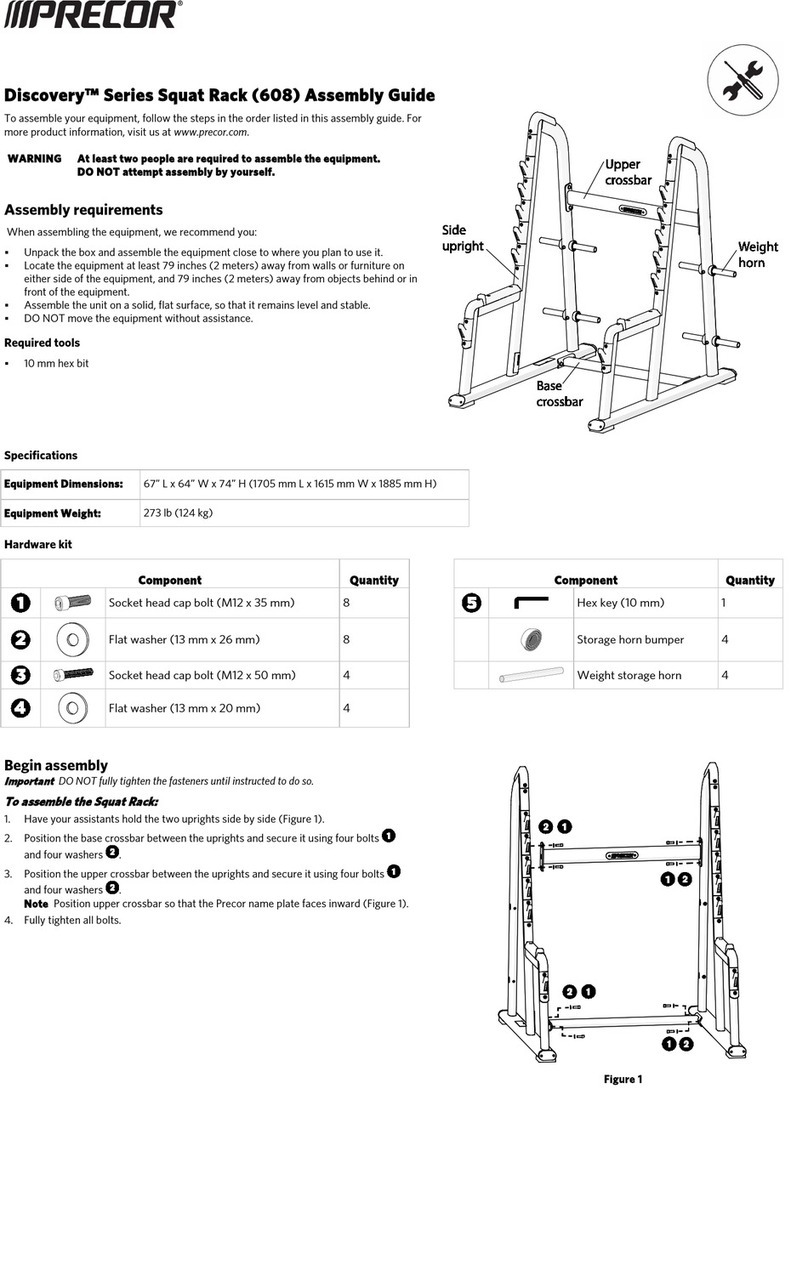

Attach movement arm to cam mounting plate and

pivot support

Figure 3

1. To attach the movement arm to the pivot support, slide one end of the axle into the pillow-

block bearing on the pivot support. Tighten the two set screws to hold the axle in place. Have

your assistant support the movement arm while you guide the movement arm onto the axle.

Your assistant should continue to support the movement arm through the rest of this

procedure.

2. Slide the cam onto the axle with the aluminum position adjustment plate facing the seat.

Note: The rubber stop on the cam should be below the welded stop on the Cam Mounting

Plate.

3. Slide the pillow-block bearing over the end of the axle. Tighten the two set screws on the

pillow-block bearing to hold the bearing on the axle.

4. Insert the cam support plate into the slot in the weight tower frame and attach the cam

support plate using:

3 – M12 x 65 mm hex head bolts

3 – 13 mm flat washers

Note: The cam support plate can be tightened completely.

5. Secure the movement arm and the pillow-block bearing to the cam support plate using:

2 - M12 x 40 mm hex head bolts (secured on the side opposite the pillow-block bearing)

2 - Barrel spacers (fit into mounting holes on pillow-block bearing)

4 - 13 mm flat washers

2 - M12 nylon lock nuts (secured on the pillow-block bearing side)

6. Secure the movement arm and the cam support plate to the pivot support tube using:

2 – M10 x 25 mm flat head cap screws

2 – Aluminum pivot caps

7. Attach the leg extension arm to the movement arm using:

1 - M10 x 25 mm flat head cap screw

1 - Aluminum pivot cap

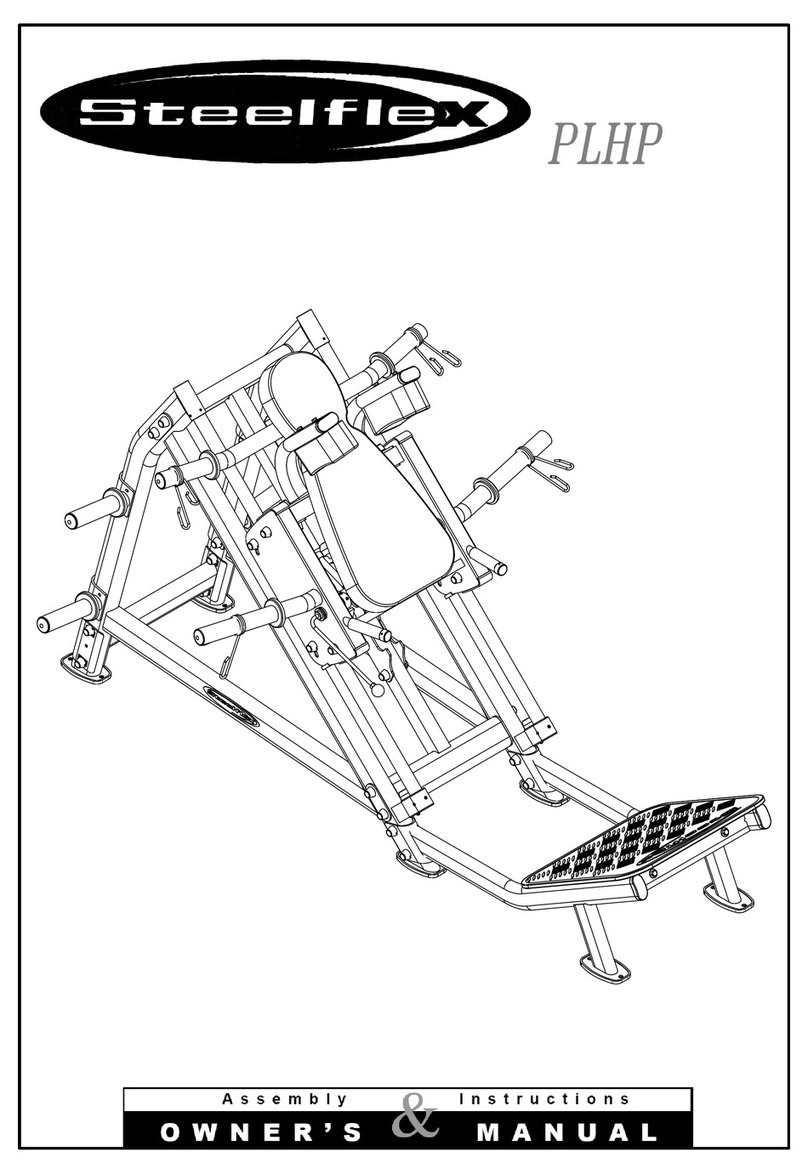

Install weight stack tower

Figure 4

1. Insert the guide rods into the holes at the bottom of the weight tower frame.

Important: A hole passes through one end of each guide rod. Be sure to insert the end

without the hole into the bottom of the frame.

2. Pull the guide rods away from the frame, keeping their lower ends engaged in the bottom of

the tower frame. Slide one weight stack bumper over each guide rod, narrow end up.

3. Check the guide rods for silicone lubricant. If you do not find any, add some of the lubricant

supplied in the hardware kit to the guide rods.

4. Carefully slide nineteen 10 lb. (4.5 kg) weight plates onto the guide rods, one by one.

5. Slide the top weight plate with weight stack stem onto the two guide rods and lower the

stem through the center holes of the weight plates.

6. If the cable assembly is attached to the top weight plate, then unscrew it and remove it at

this time. Slide the ring at the end of the tether of the weight selection pin over the right-hand

post on the top weight plate.

7. Secure the weight stack assembly to the weight tower frame. Slide an O-ring onto the smaller

diameter shoulder of each guide rod locking collar, then slide the collars onto the guide rods

(the smaller diameter shoulder on the collar should be facing up). Re-align the guide rods with

the mounting holes at the top of the weight tower.

8. Have your assistant hold the guide rods in place. Slide the collars up until the shoulder of

each collar fits into the tower frame. Insert one M6 × 45 mm button head cap screw through

the holes in each collar and each guide rod, then attach an M6 nylon lock nut to each button

head cap screw. Tighten the button head cap screws securely, then attach and tighten the M8

set screws using the S4 hex key.

©2021 Precor Incorporated |VSL Leg Extension|Assembly Guide |P/N CWR057777-102 ENU 31 July 2021 |2